Ship oiling system risk prealarming method

A technology of risk early warning and lubricating oil system, applied in the direction of pressure lubricated lubricating safety devices, etc., can solve problems such as intricate relationships, and achieve the effect of speeding up the process of informatization, ensuring safety, and improving maintenance and management levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

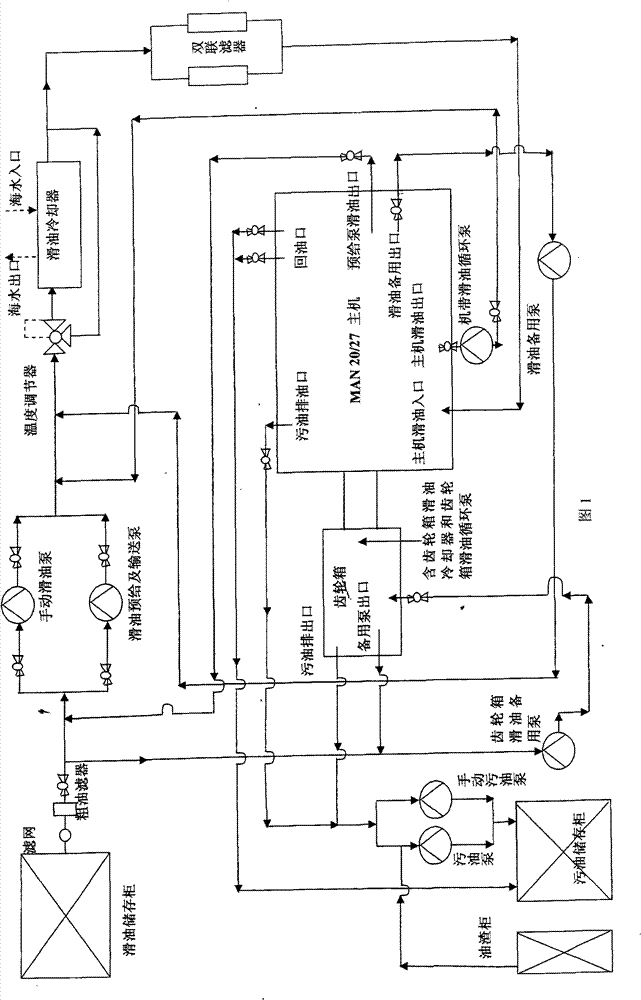

[0050] Usually, the main engine lubricating oil system of a ship includes the following equipment: lubricating oil storage cabinet, dirty oil storage cabinet, oil residue tank, filter screen, crude oil filter, duplex filter, manual lubricating oil pump, machine belt lubricating oil circulation pump, lubricating oil Pre-supply and delivery pumps, dirty oil pumps, manual dirty oil pumps, lubricating oil coolers, thermostats, valves (pressure regulating valves, check valves, etc.), piping systems (oil main pipe branch pipes, oil return pipes, oil suction pipes, oil overflow pipes, etc.)

[0051] General ship lubricating oil system risk warning schematic diagram figure 1 Shown: The oil pump sucks the lubricating oil from the belt oil pan through the pipeline, through the temperature regulator and cooler, or through the bypass pipeline to the oil filter, and then to the oil main pipe on the engine. When the engine starts, the bearing lubricating oil is provided by the pre-feed pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com