Star shaped compressing mechanism

A technology of a compression mechanism and a compressor shell, applied in the field of compressors, can solve the problems of parts replacement, difficult maintenance, poor balance and reliability, short service life of valve plates, etc., and achieves good balance and reliability, The effect of smooth movement and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

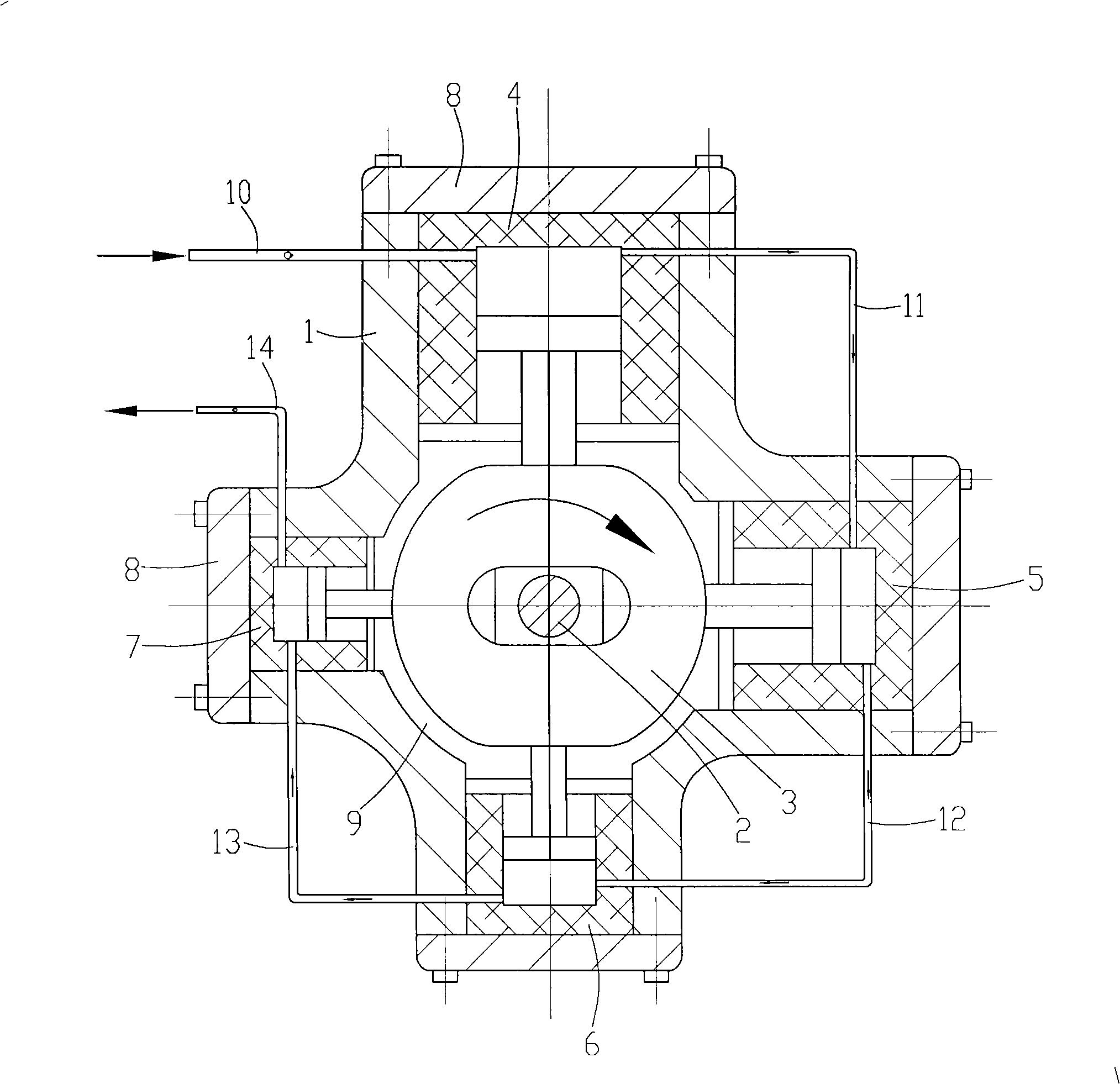

[0019] Such as figure 1 As shown, the present invention consists of a compressor housing 1, a motor main shaft 2, a drive wheel 3, a first-stage cylinder 4, a second-stage cylinder 5, a third-stage cylinder 6, a fourth-stage cylinder 7, an end cover 8, an air intake pipe 10, a first The air pipe 11, the second air pipe 12, the third air pipe 13 and the exhaust pipe 14 are composed of components, wherein the middle part of the compressor housing 1 is the working chamber 9, and the periphery of the working chamber 9 has four cylinders for installation. The four accommodating cavities are distributed symmetrically in a cross, the inner end of each accommodating cavity communicates with the working chamber 9, and the outer end of the accommodating cavity is sealed by an end cover 8, which is connected to the compressor through screws. The housing 1 is fixed. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com