Mini water pump

A technology of miniature water pumps and water levels, applied to pumps, pump devices, pump components, etc., can solve the problems of shortening the service life of water pumps, and achieve the effects of reduced power consumption, long service life and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

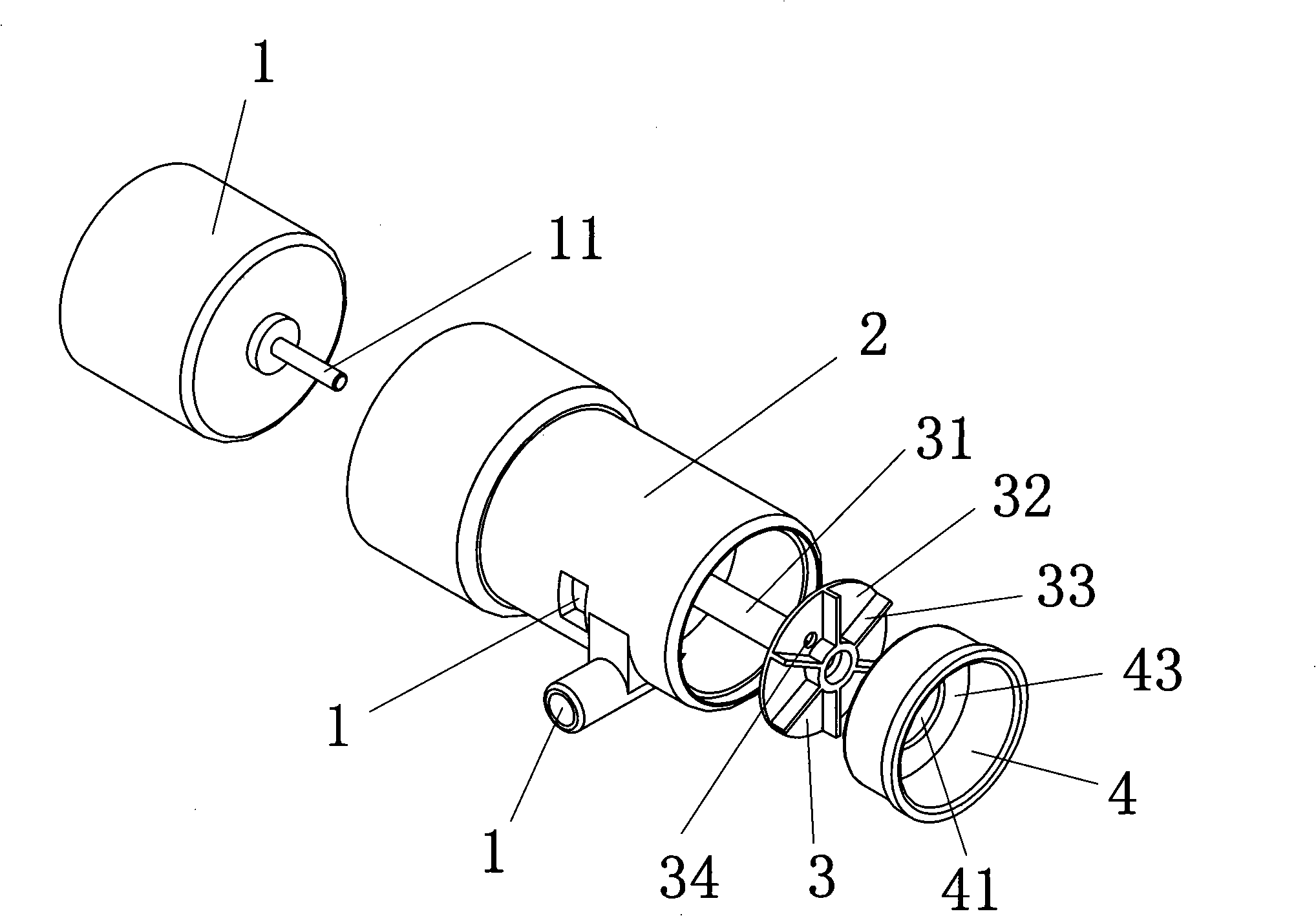

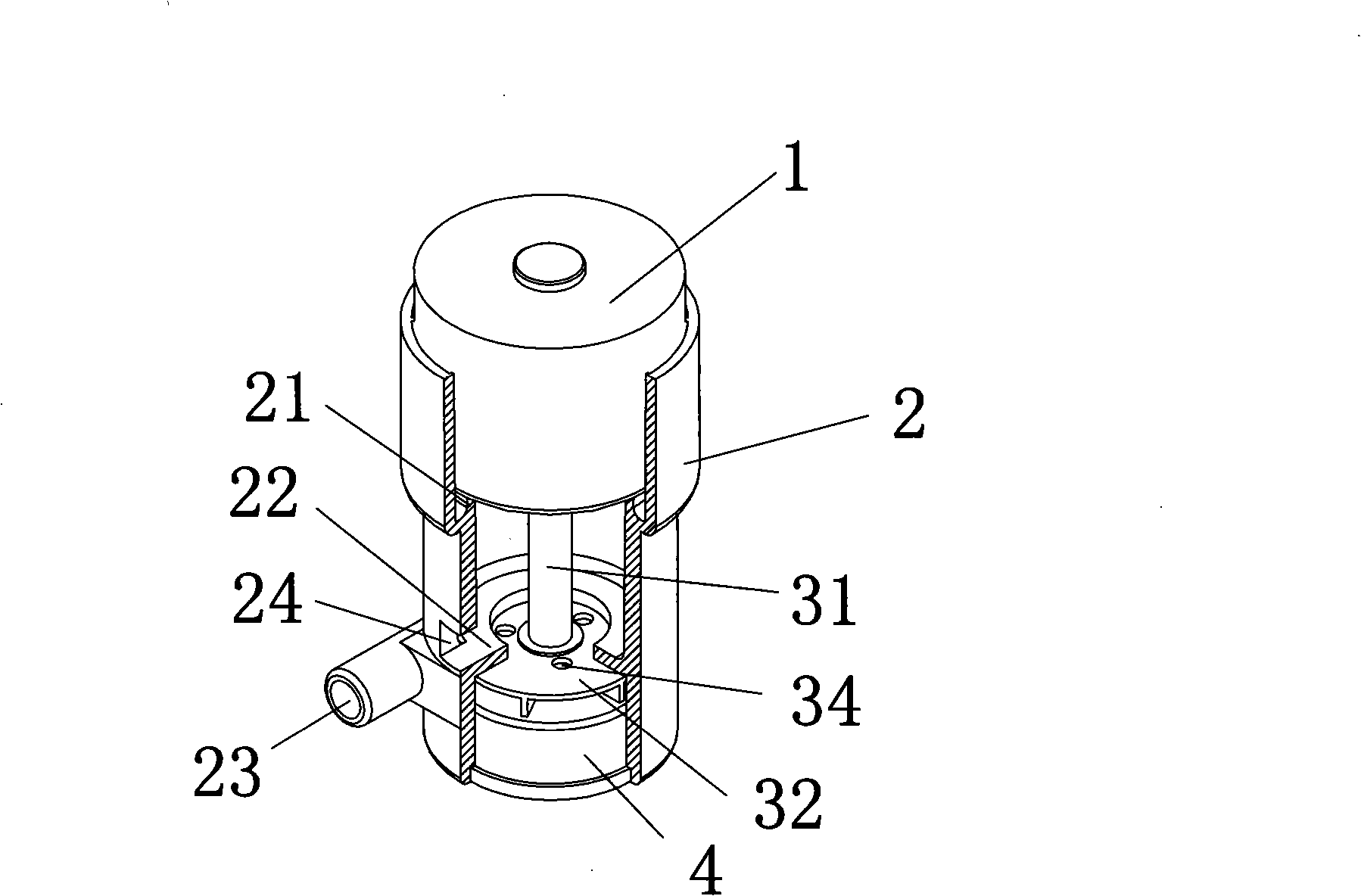

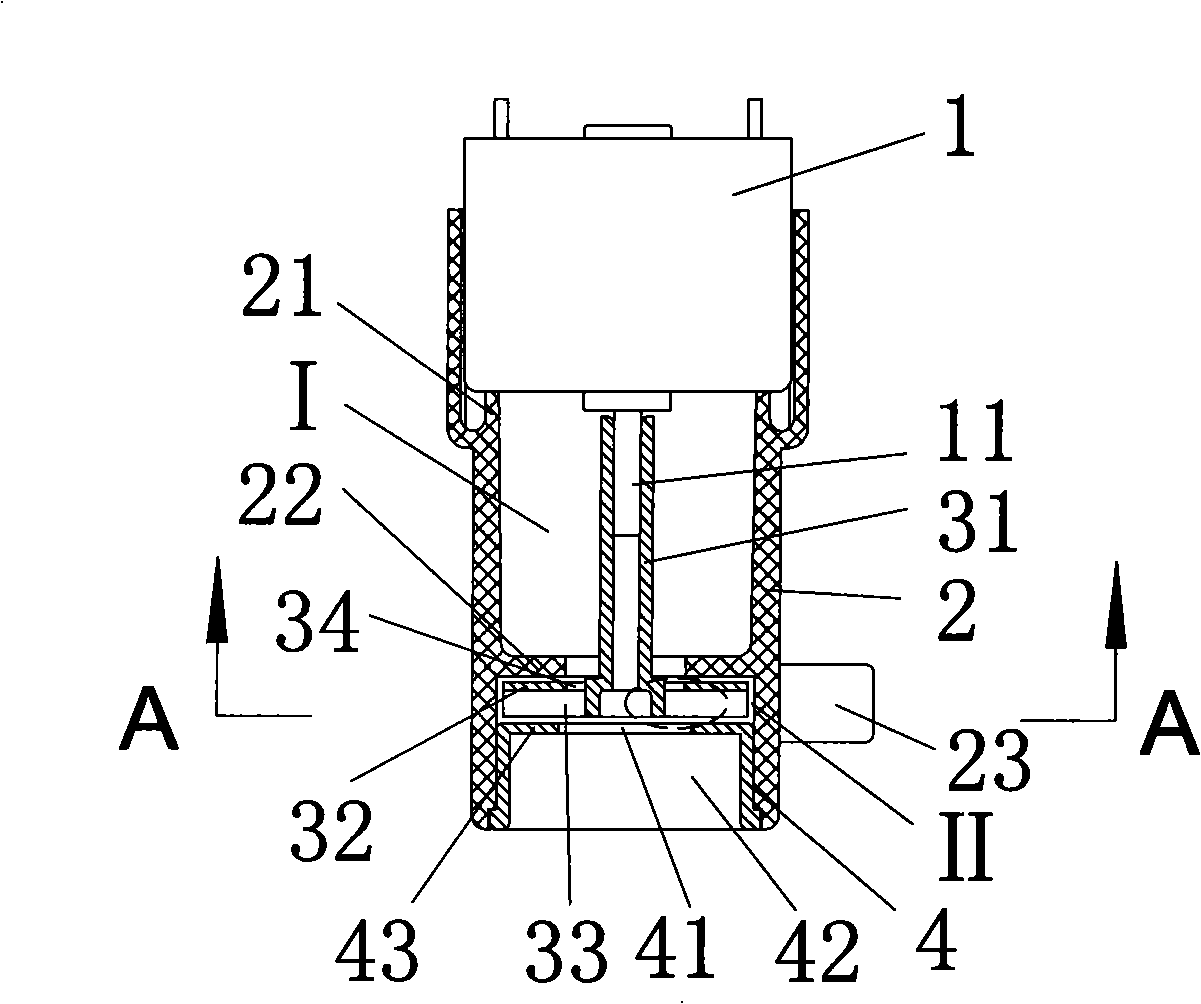

[0016] see Figure 1 ~ Figure 4 , this embodiment includes a motor 1, a housing 2, an impeller 3 and an end cover 4, the inner wall of the housing 2 is provided with an outwardly protruding flange 21 and a boss 22, and the outer wall of the housing 2 is provided with an outlet along its tangential direction. The water outlet 23 has a water level hole 24 parallel to the end surface of the housing 2 on the circumferential wall of the housing 2, the water level hole 24 is located above the water outlet 23, and the lower edge of the water level hole 24 is flush with the upper edge of the boss 22 , that is, the lower edge of the water level hole 24 and the upper edge of the boss 22 are on the same plane. The impeller 3 is composed of an integrated impeller shaft 31, a chassis 32 and six blades 33, the impeller shaft 31 is located above the chassis 32, and the six blades 33 are uniformly distributed under the chassis 32 in a radial form centered on the center of the chassis 32 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com