Crystallizer on-line width modulation system and its method

A crystallizer and width adjustment technology, applied in the direction of using feedback control, etc., can solve problems such as loss of raw materials and time, reduce production efficiency, increase production cost, etc., to reduce slab defects, prevent steel breakout accidents, and eliminate gas. gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

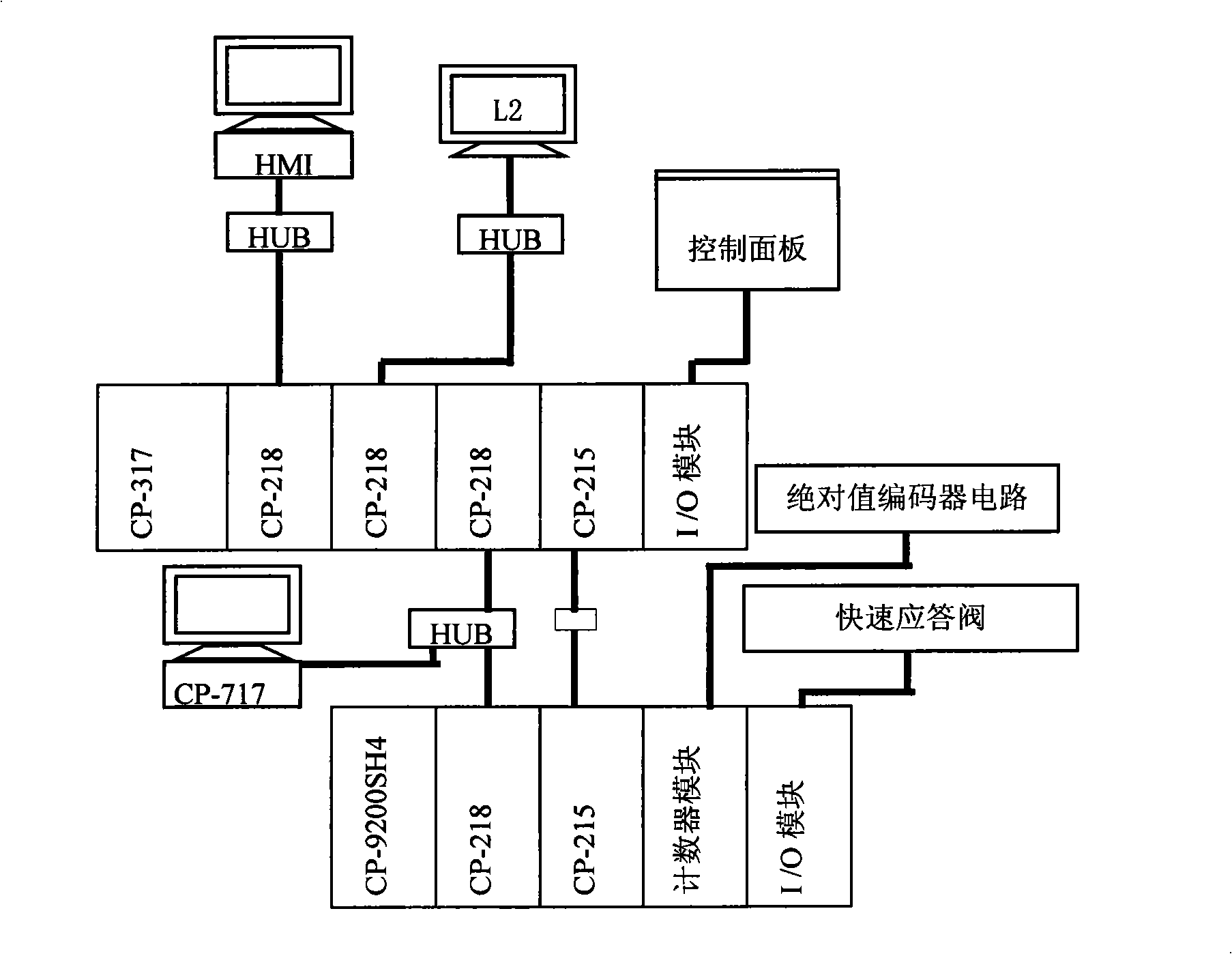

[0046] Such as figure 1 As shown, a crystallizer online width adjustment system, including,

[0047] Two opposite crystallizers,

[0048] A driving device arranged outside the two crystallizers and receiving control signals to adjust the width between the two crystallizers;

[0049] Absolute encoder circuit, used to collect and output the actual value of the crystallizer position;

[0050] Programmable logic controller (PLC), connected to the absolute encoder circuit, accepts the actual value and the target value input from the outside, and outputs a control signal to the drive device according to the target value and the actual value;

[0051] Wherein, the driving device includes a quick-response valve and a stepping electro-hydraulic cylinder (referred to as a stepping cylinder) pneumatically connected to the quick-response valve, and the stepping cylinder is connected to the crystallizer. The quick-response valve QSV can be a product with the model number HS-G01-AR-D2B-1...

Embodiment 2

[0058] A crystallizer online width adjustment method is characterized in that comprising the following steps:

[0059] 1) Compare the current actual value and the final target value of the two crystallizers to determine whether it is widening or narrowing, if it is widening, then enter step 2), if it is narrowing, then go to step 3);

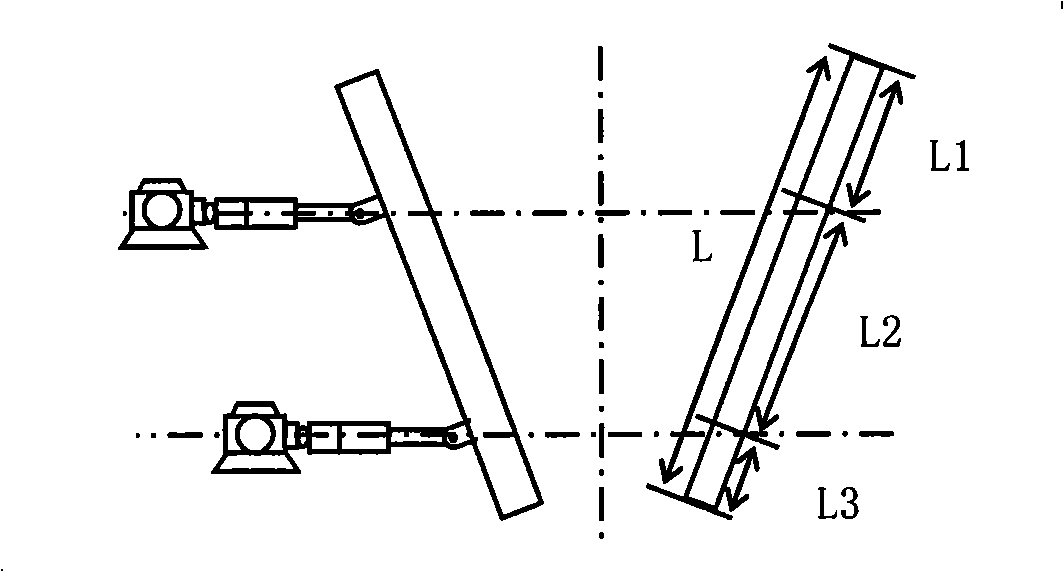

[0060] 2) Translation, that is, horizontal translation of the crystallizer;

[0061] 3) Taper adjustment, that is, maintain the width of the short side or long side between the two crystallizers, and adjust the taper between the two crystallizers towards the final target value;

[0062] 4) Amplitude modulation, that is, maintaining the taper between the two crystallizers, and adjusting the relative distance between the two crystallizers towards the final target value;

[0063] 5) Taper adjustment, that is, maintain the width of the long side or short side between the two crystallizers, and adjust the taper between the two crystallizers towards ...

Embodiment 3

[0067] A crystallizer online width adjustment method, comprising the following steps:

[0068] A Judgment step

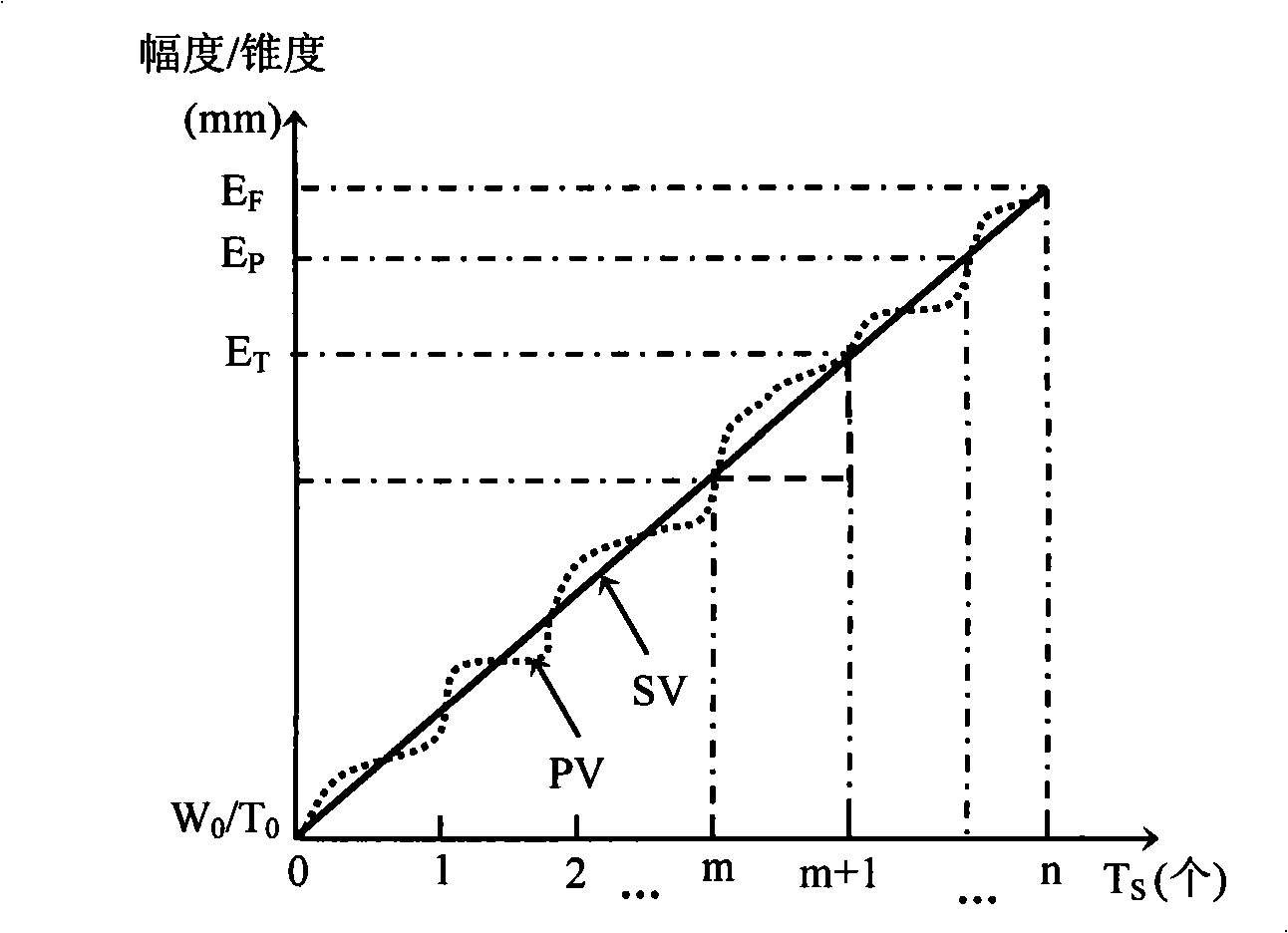

[0069] A1. According to the current actual value and the final target value of the two crystallizers, and set one or more stage target values according to the actual value and the final target value, the target value of the stage is between the actual value and the target value; by setting The target value of the stage is determined, so that the adjustment of the crystallizer can be divided into multiple steps. The target value of the stage can be set according to the mechanical parameters, the current actual value and the final target value.

[0070] A2. Set the next target value to the value closest to the current actual value in the direction of the final target value among the stage target value and the final target value, and determine whether it is widening or narrowing. If it is widening, go to step B , if it is narrowing, go to step C;

[0071] B Width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com