LED encapsulation having cooling pin and manufacturing method therefor

A technology for light-emitting diodes and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of difficulty in manufacturing, rising manufacturing costs, detachment of heat sinks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

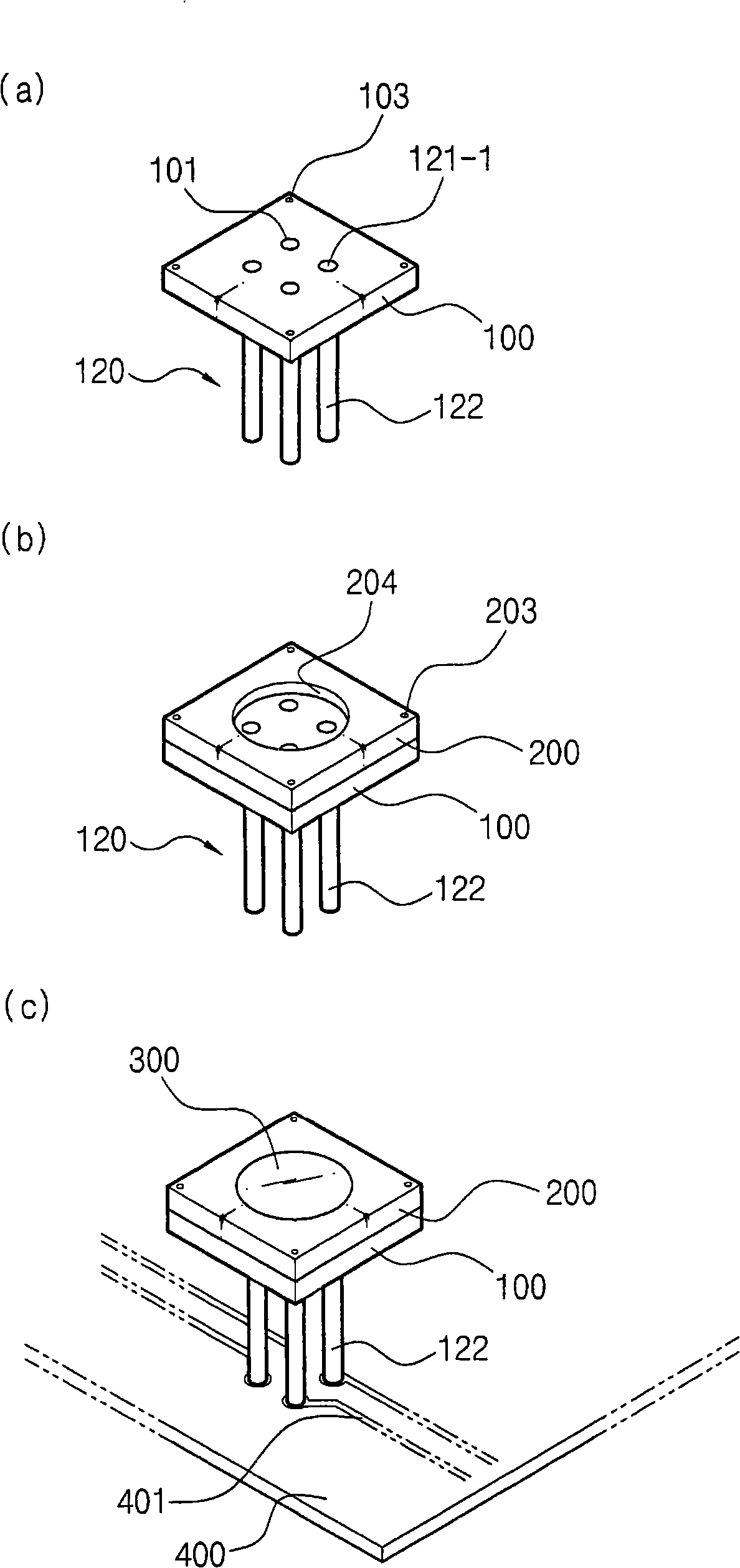

[0024] exist figure 1 (a) to (c) show the structure of a light emitting diode package according to one embodiment of the present invention.

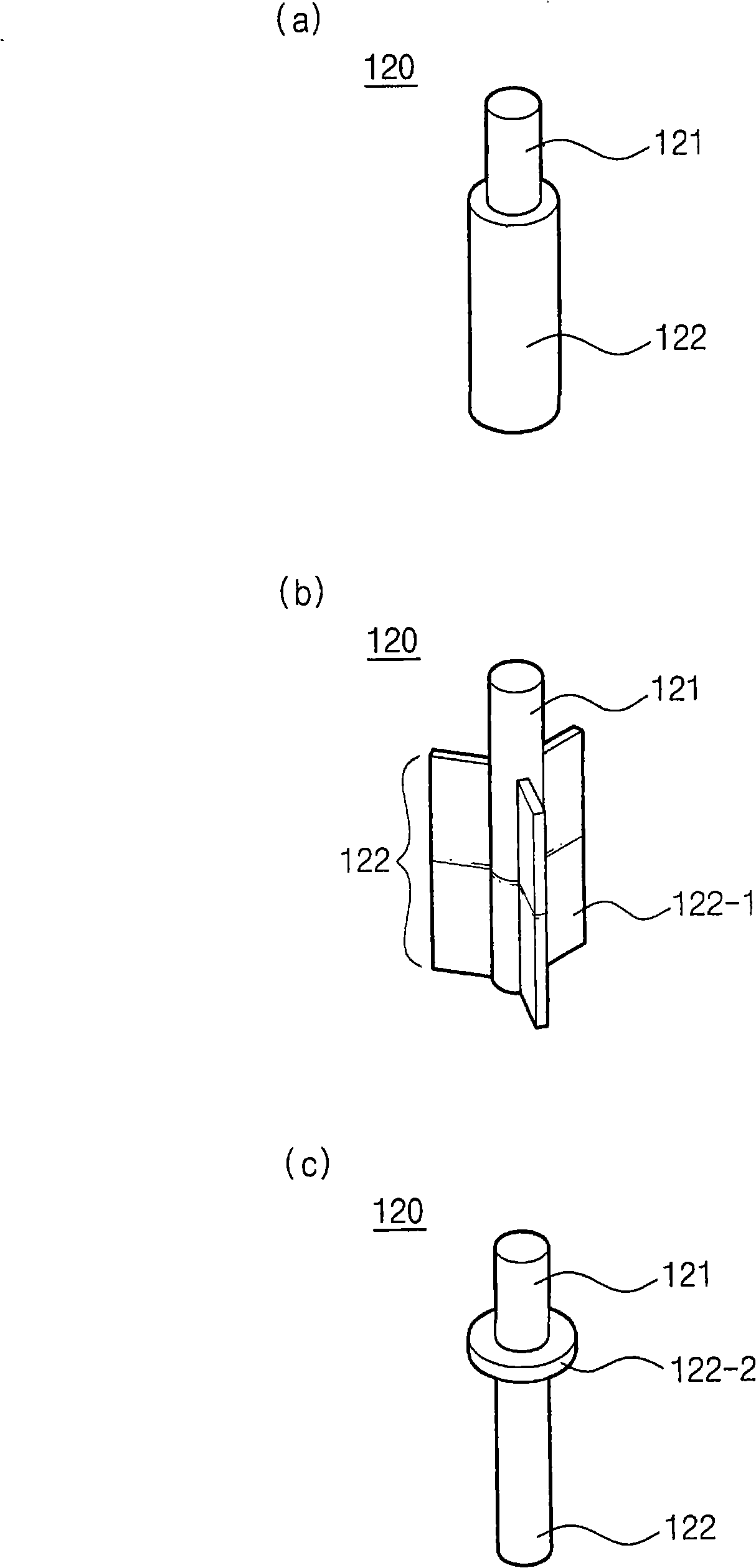

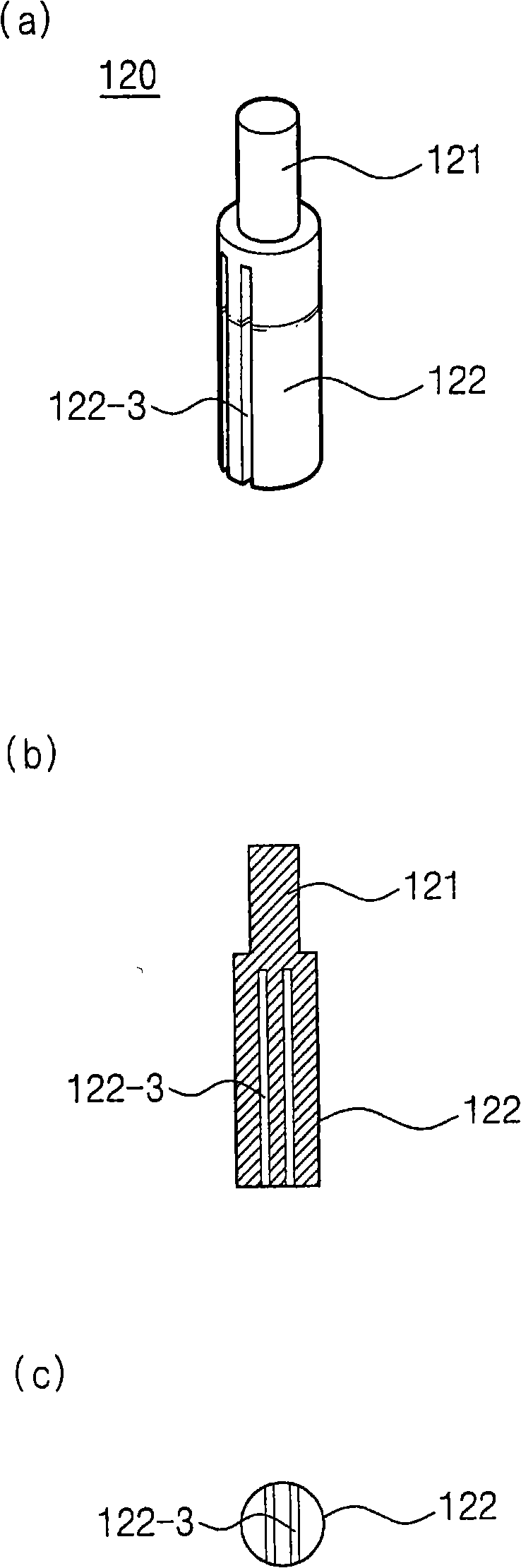

[0025] First, if figure 1 As shown in (a), the light-emitting diode package according to one embodiment of the present invention consists of a substrate part 100 and a heat dissipation pin 120 that is riveted to one side of the substrate part and protrudes to the other side of the substrate part. constitute.

[0026] The substrate unit 100 may be formed of a printed circuit board or an insulating resin material such as plastic, and is preferably formed of a printed circuit board. In addition, on the above-mentioned base plate part 100, in order to realize the riveting of the heat dissipation pin and it, one end portion for inserting the heat dissipation pin 120 is vertically opened, that is, the insertion part 121 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com