Thermal management in large area flexible OLED assembly

一种有机发光装置、大面积的技术,应用在光源领域,达到延长使用寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

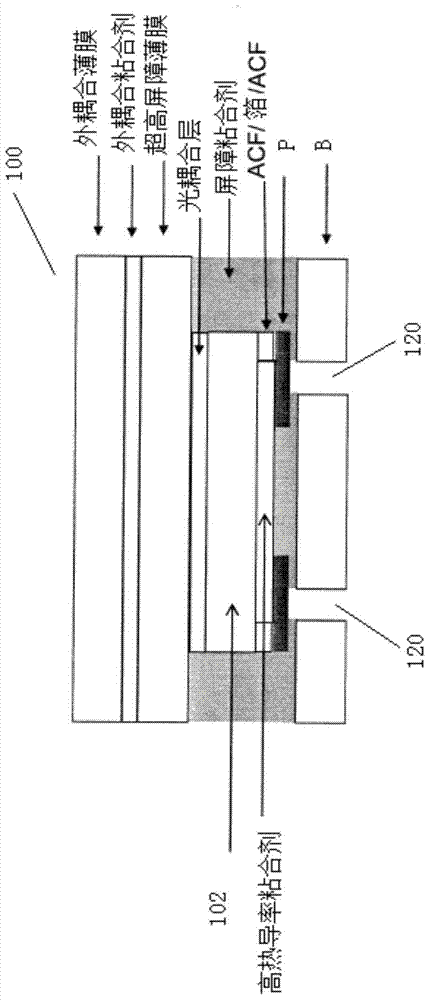

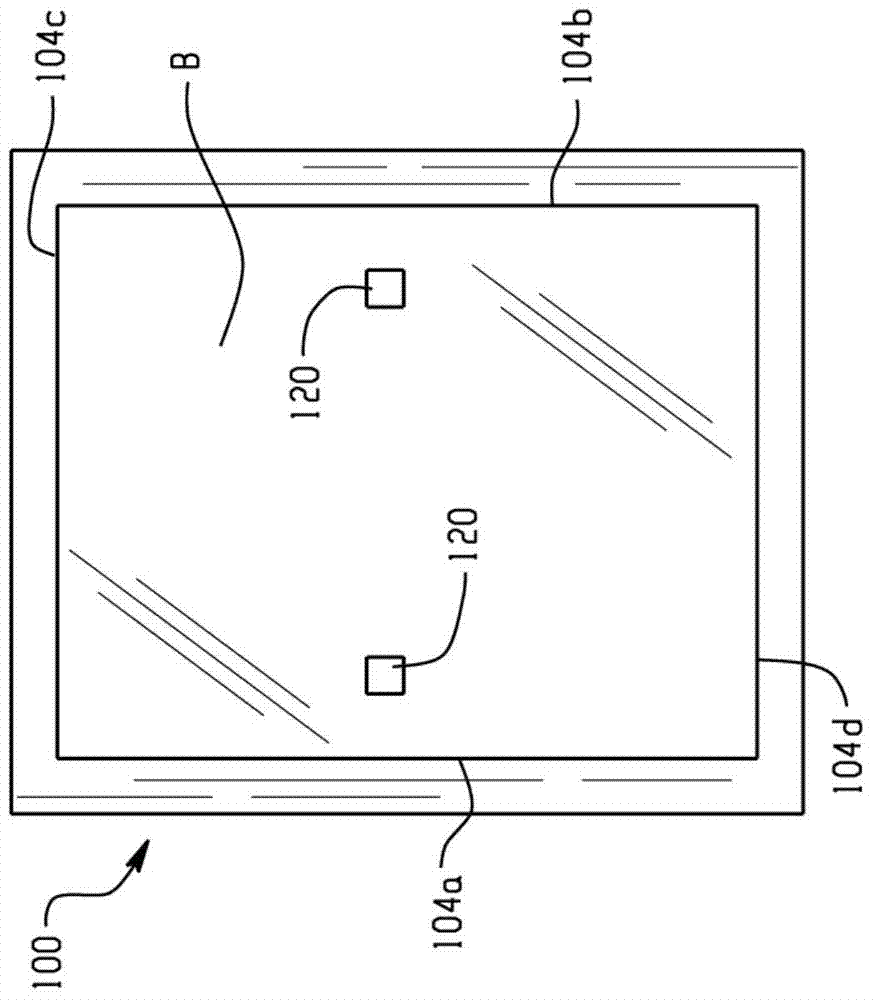

[0032] For the purposes of the following description, the specific details of a generally planar flexible light source or OLED device are generally well known to those skilled in the art. Accordingly, further descriptions in this specification are considered unnecessary in order to enable a full and complete understanding of the present invention. Those details required by the invention are provided below and illustrated in the accompanying drawings. As used in this specification, the term "lighting component" refers to any component of all or some of the constituent materials described in this specification, including at least a light source and a connector cable for providing electrical power to the component. The light source may be an OLED device or panel comprising at least one hermetically sealed OLED device. Although the preferred arrangement of the lighting assembly is a large area flexible lighting assembly, selected aspects may also be applied in other lighting solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com