Active magnetic refrigerator

A magnetic refrigerator, active technology, applied in refrigerators, refrigeration and liquefaction, machines using electric/magnetic effects, etc., can solve the problems of heat exchange efficiency decline, loss, and inability to control the amount of heat transfer fluid, etc., to achieve installation Simplification, improvement of heat exchange efficiency, and excellent layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

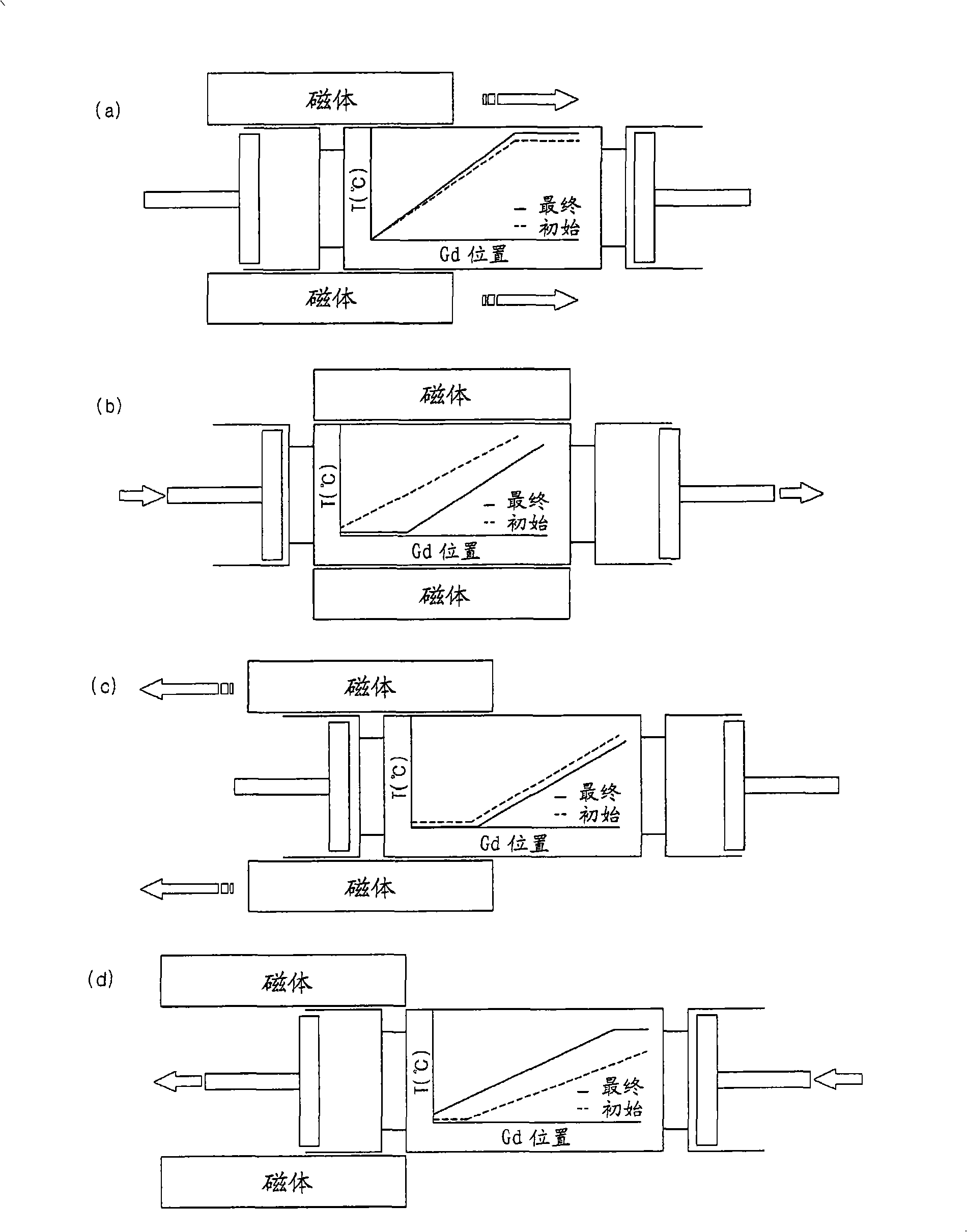

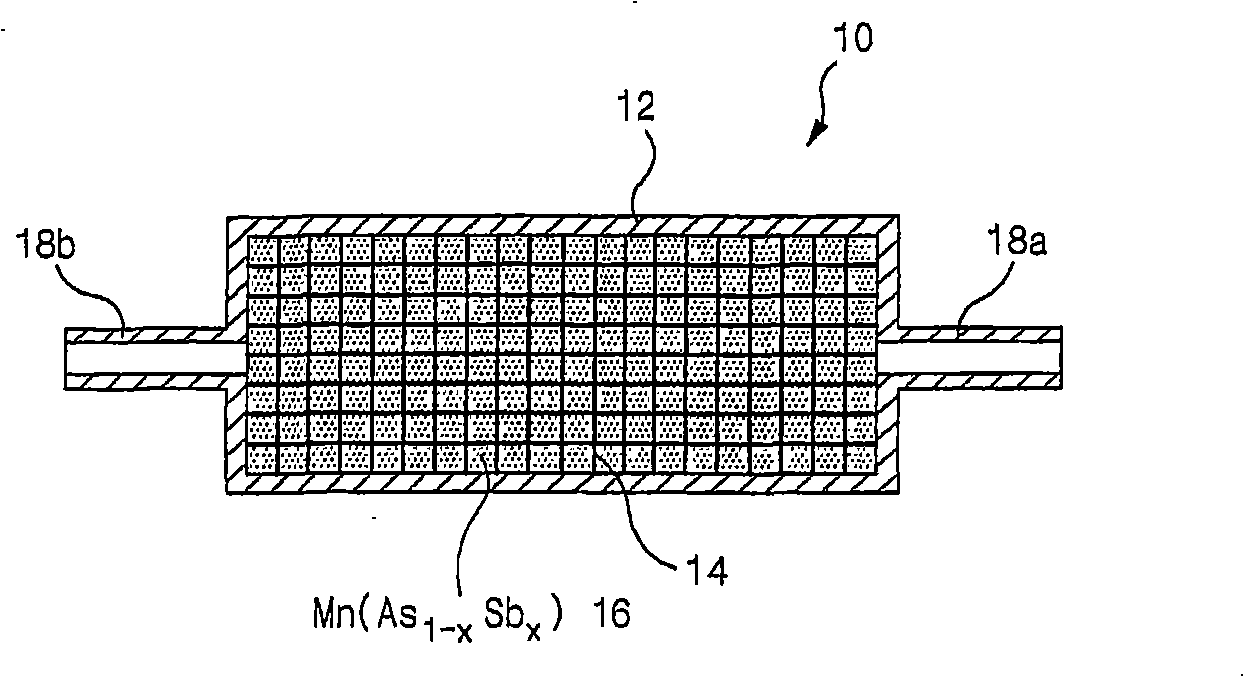

[0090] Image 6 is a configuration diagram showing a magnetic refrigerator according to a first preferred embodiment of the present invention. Figure 7 is for Image 6 The plan view of the magnet unit of the active magnetic refrigerator, while Figure 8 is for Image 6 Perspective view of the exterior of the magnetic heat exchange unit of the active magnetic refrigerator.

[0091] like Figure 6 to Figure 8 As shown, the active magnetic refrigerator according to this preferred embodiment of the present invention includes a first magnetic heat exchange unit 113A and a second magnetic heat exchange unit 113B with magnetocaloric materials, for supplying Two magnetic heat exchange units 113B, the magnet unit 140 applying a magnetic field or canceling their magnetic field, the hot heat exchanger 162, the cold heat exchanger 163, the first solenoid valve 120a and the second solenoid valve 120b.

[0092] The heat transfer fluid is divided into first heat transfer fluids 17aa an...

no. 2 approach

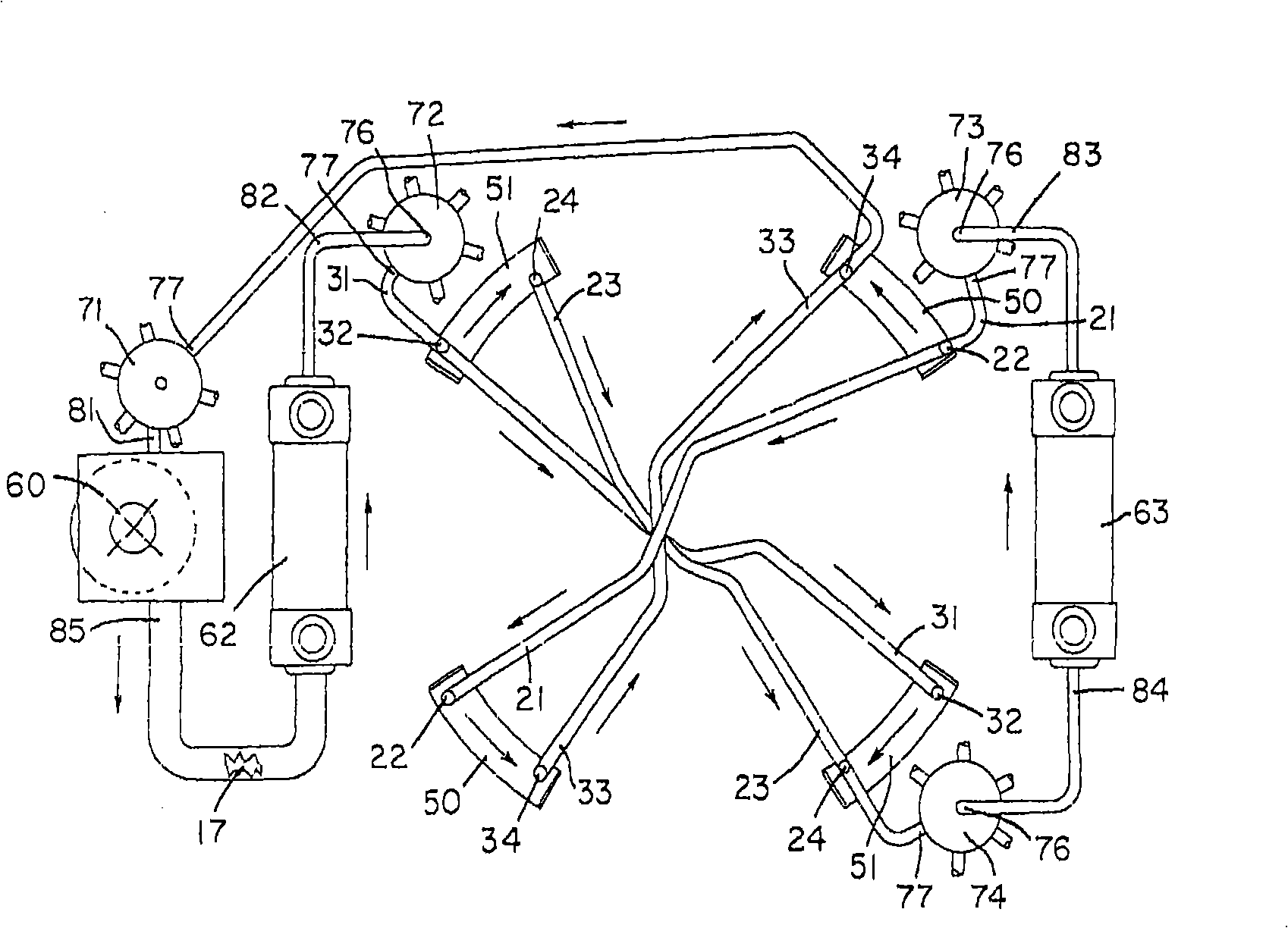

[0139] Figure 14 and Figure 15 is a plan view showing the circulation of the heat transfer fluid of the active magnetic refrigerator according to the second preferred embodiment of the present invention according to the position of the magnet, Figure 16 is shown simultaneously Figure 14 and Figure 15 The floor plan of the cycle, Figure 17 is a schematic diagram representing the rotating assembly of the magnet, while Figure 18 and Figure 19 It is a perspective view and a partially enlarged view of a guide table having a flow path.

[0140] like Figure 14 to Figure 19As shown, the active magnetic refrigerator according to this preferred embodiment of the present invention includes first magnetic heat exchange units 113A and 133A' and second magnetic heat exchange units 113B and 113B' containing magnetocaloric materials, accessories to the magnetic heat exchange units The magnet 1141 of 113A, 113A', 113B and 113B', the magnet rotating assembly 1140 for applying an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com