Cam swing-link interlock control type compact printer

A micro-printer and cam pendulum technology, applied in typewriters, printing devices, printing, etc., can solve the problems of laborious opening of the paper warehouse door, and achieve the effect of solving laborious opening, stable joint control action, and flexible opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

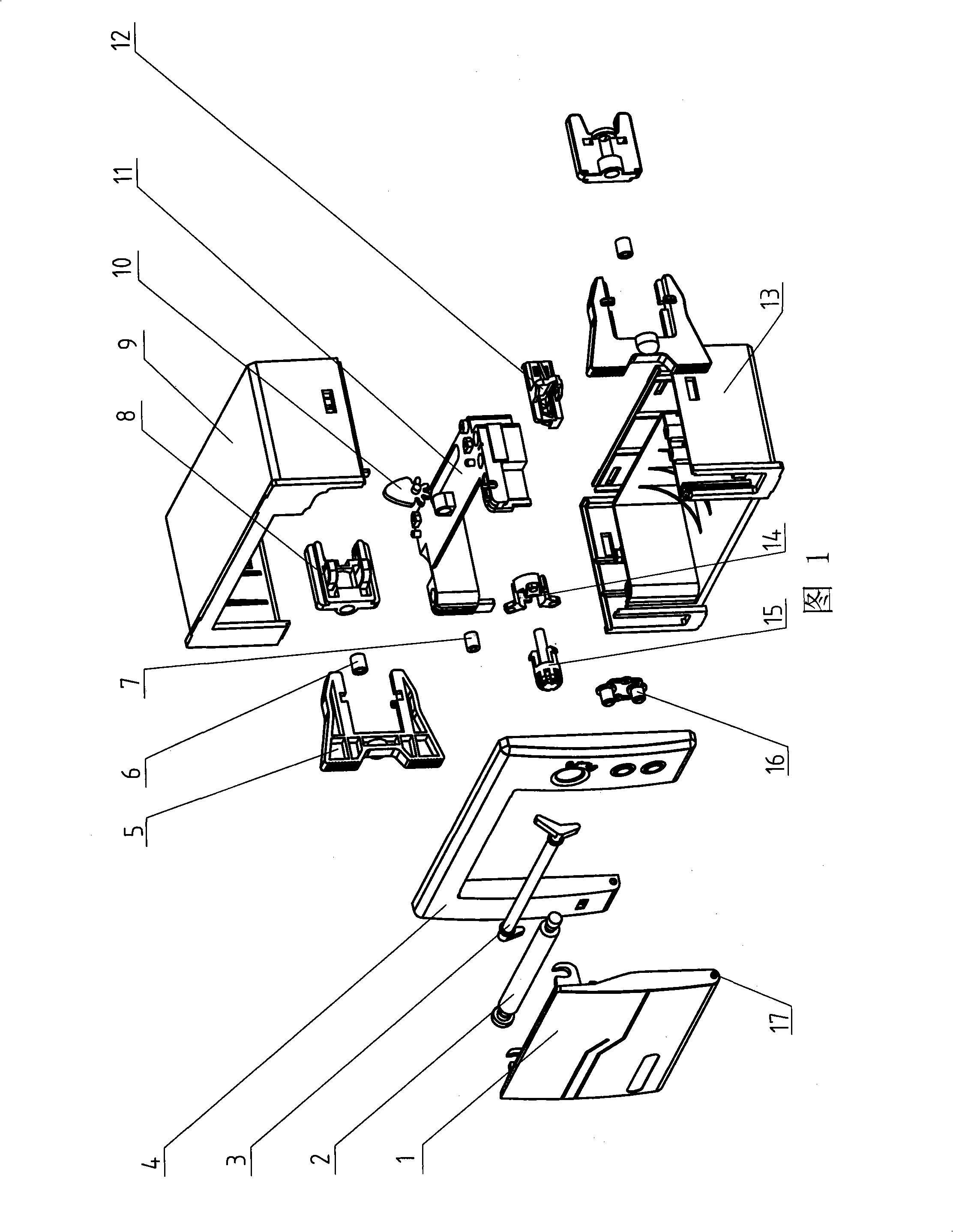

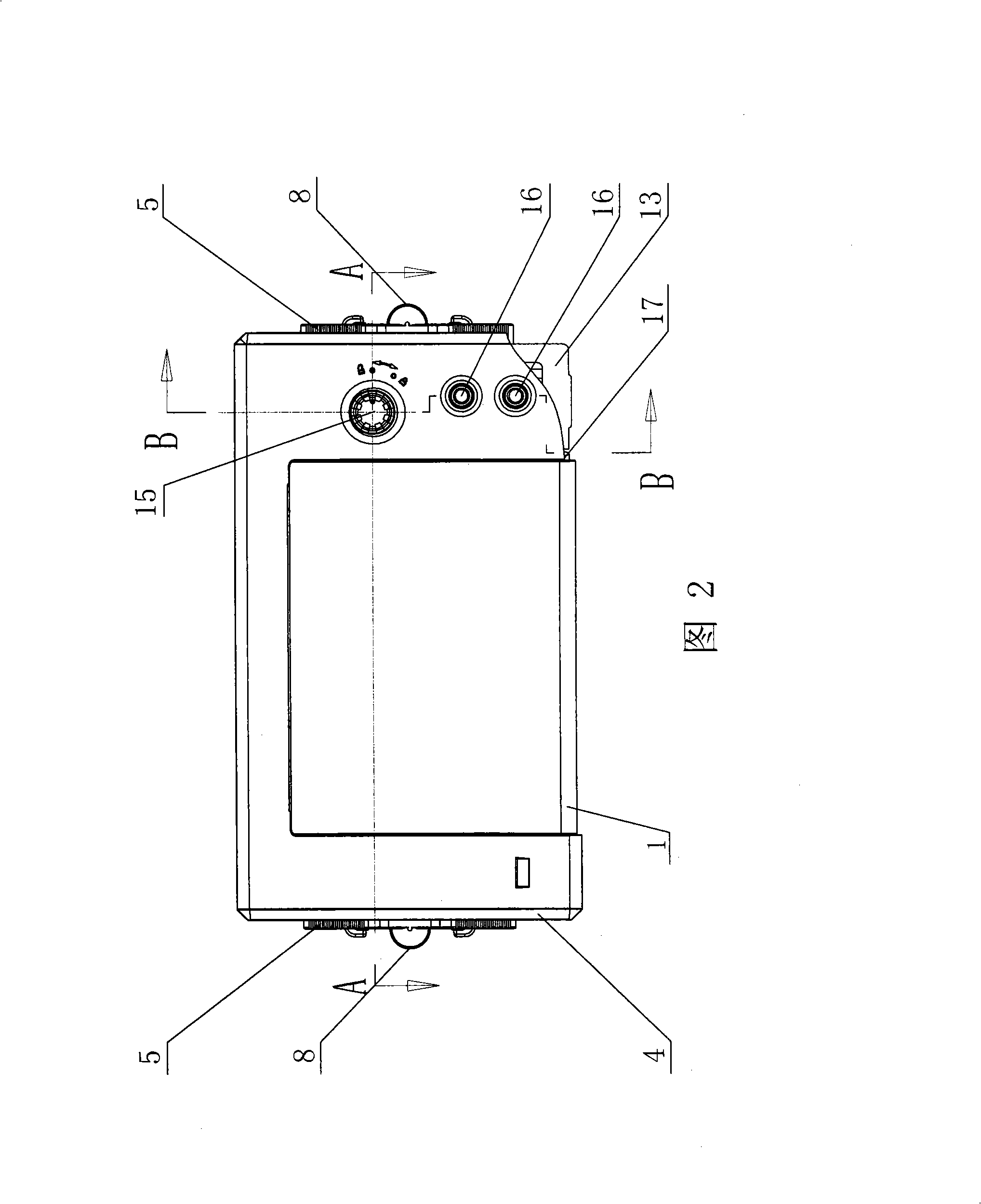

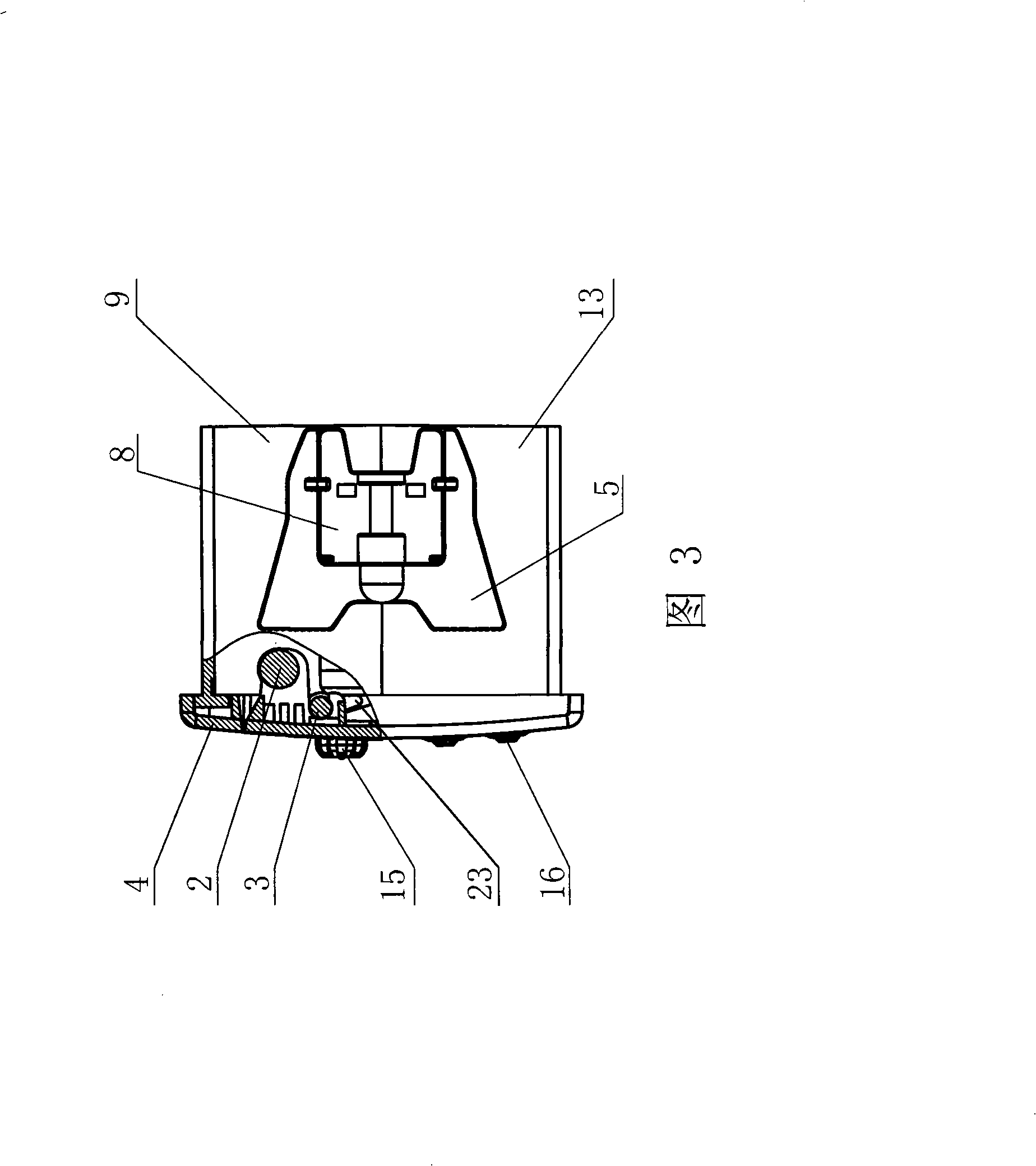

[0018] The specific structure of the present invention will be described in detail with reference to FIGS. 1 to 9 . This cam swing rod joint control type micro-printer includes a panel 4 with a paper bin door 1, a housing made up of upper and lower shells 9, 13, a printing unit (not shown) and its holder assembled in the housing. Frame 11 and the fixed screw sleeve 7 of fixed printing unit, the button 15 of paper bin door opener, the two ends are provided with parts such as the fork 3 of large and small crank wall 24,23, sliding bearing 12 and toothed cam 10. The specifications and shapes of the housing, the door panel 4 assembled with the paper warehouse door 1, the control buttons 16, the buttons 15 and the indicator light display ports, and the paper warehouse door 1 etc. should be selected according to the actual use requirements, and assembled in the housing. The control circuit board, printing unit, ribbon and other components in the body (not shown in the figure) are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com