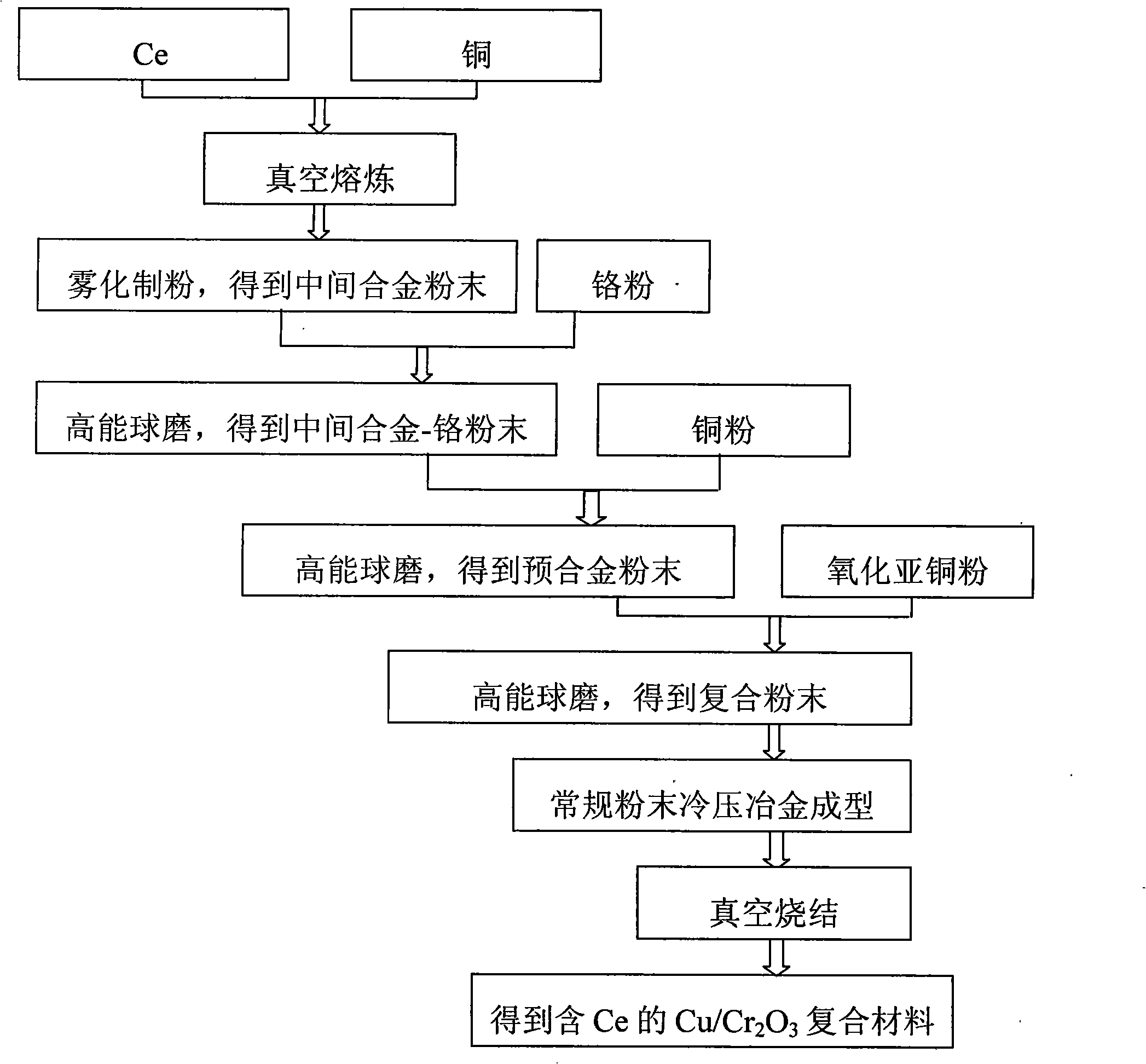

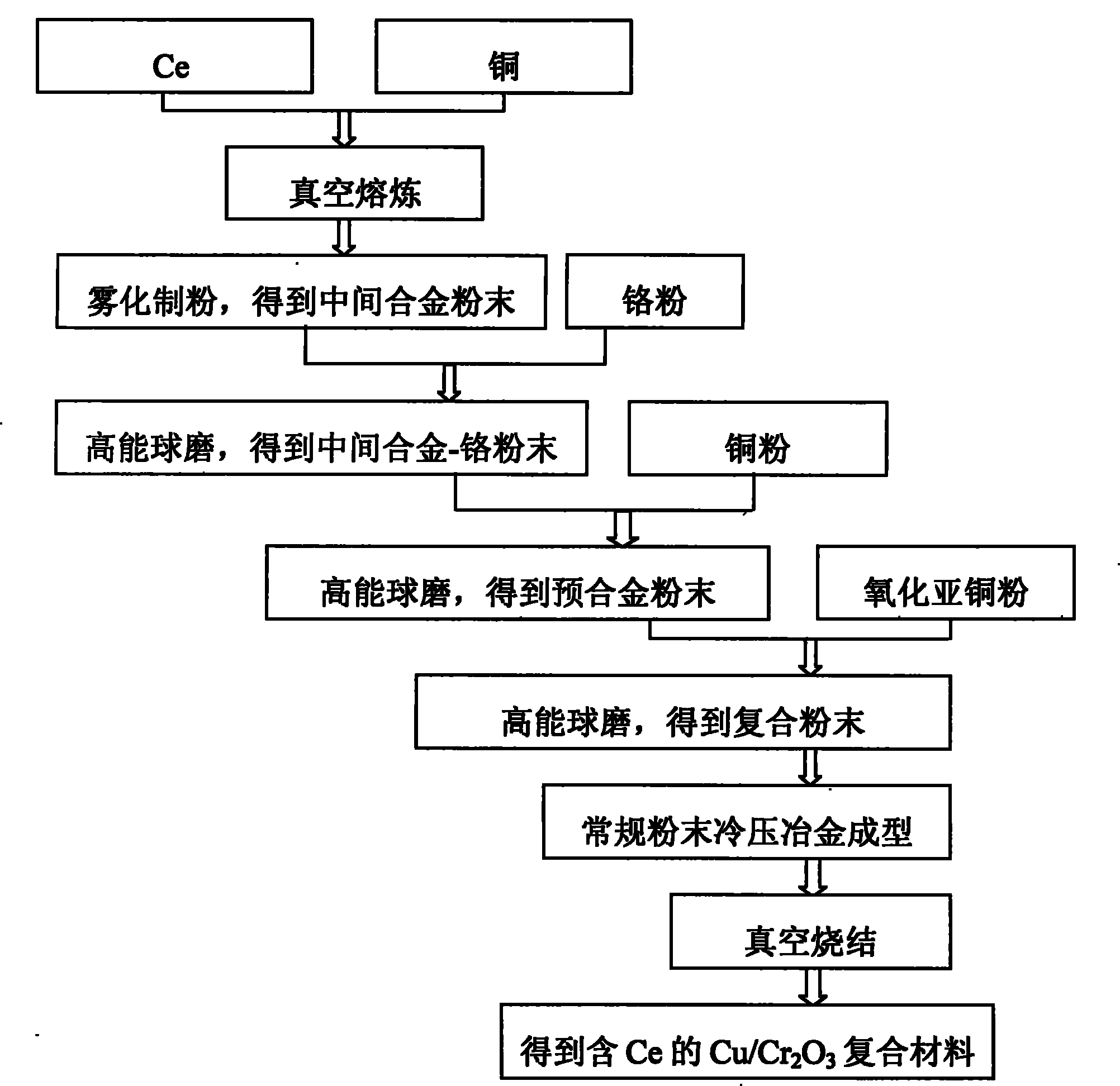

Method for preparing Cu/Cr2O3 composite material from Ce-CuCr prealloy powder

A pre-alloyed powder and composite material technology, which is applied in the field of metal matrix composite material preparation, can solve the problems of slow oxidation rate, oxide grain boundary segregation, and wide application of limited internal oxidation methods, so as to achieve grain refinement and high temperature improvement. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Drill a copper rod, put thin strips of Ce into the hole, seal it with copper powder and put it in a crucible, use a ZRS-18Q microcomputer program-controlled vacuum sintering furnace for melting, and smelt it into Cu-Ce with Ce accounting for 10% of the total weight master alloy. The melting process is: the degree of vacuum is 10 -2 Pa, raise the temperature to 900-920°C in 40 minutes, keep it warm for 20 minutes, then continue to raise the temperature to 1180-1200°C, hold it for 30 minutes, and finally cool it with the furnace to get a Cu-Ce master alloy; atomize into powder, and sieve the powder to obtain Cu-Ce master alloy powder with a particle size of 100-200 microns.

[0027] Take respectively the copper powder 50g of average particle size 55 microns, the chromium powder 1.5g of average particle size 55 microns and the Cu-Ce master alloy powder 0.3010g that last step makes (make Ce content be 0.05wt% of copper, so required Ce The amount of Cu-Ce is 0.025g, then t...

Embodiment 2

[0031] Prepare Cu-Ce master alloy powder by the method described in embodiment 1, control vacuum tightness is 10 -3 Pa, the smelting process is: raise the temperature to 900°C in 40 minutes, keep it warm for 25 minutes, then continue to raise the temperature to 1180-1200°C, and hold it for 35 minutes.

[0032]Take respectively the copper powder 50g of average particle size 55 microns, the chromium powder 1.5g of average particle size 55 microns and the Cu-Ce master alloy powder 0.6020g that last step makes (make Ce content be 0.1wt% of copper, so required Ce The amount of Cu-Ce is 0.05g, then the amount of master alloy Cu-Ce to be added during ball milling is 0.05÷(10%×83.06%)=0.6020g, wherein the master alloy for smelting is Cu-10Ce, and the absorption rate of Ce is 83.06% ).

[0033] Put 0.6020g of Cu-Ce master alloy powder, 1.5g of chromium powder and a small amount of alcohol into a horizontal ball mill at 100-120r / min for ball milling, control the ball milling speed to 1...

Embodiment 3

[0036] Prepare Cu-Ce master alloy powder by the method described in embodiment 1, control vacuum tightness is 0.5 * 10 -2 Pa, the smelting process is: raise the temperature to 900-920°C in 40 minutes, hold it for 23 minutes, then continue to raise the temperature to 1180-1200°C, hold it for 33 minutes.

[0037] Take respectively the copper powder 50g of average particle size 55 microns, the chromium powder 1.5g of average particle size 55 microns and the Cu-Ce master alloy powder 0.7224g that last step makes (Ce content is 0.12wt% of copper, so required Ce The amount is 0.06g, then the amount of master alloy Cu-Ce to be added during ball milling is 0.06÷(10%×83.06%)=0.7224g, wherein the master alloy for smelting is Cu-10Ce, and the absorption rate of Ce is 83.06%) .

[0038] Put 0.7224g of Cu-Ce master alloy powder, 1.5g of chromium powder and a small amount of alcohol into a horizontal ball mill at 100-120r / min for ball milling, control the ball milling speed to 110r / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com