Method and system for determining drilling fluids leakage and overflow

A technology of drilling fluid and leakage, which is applied in the directions of surveying, earthwork drilling and production, wellbore/well components, etc., and can solve problems such as the lack of public methods for determining leaky layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

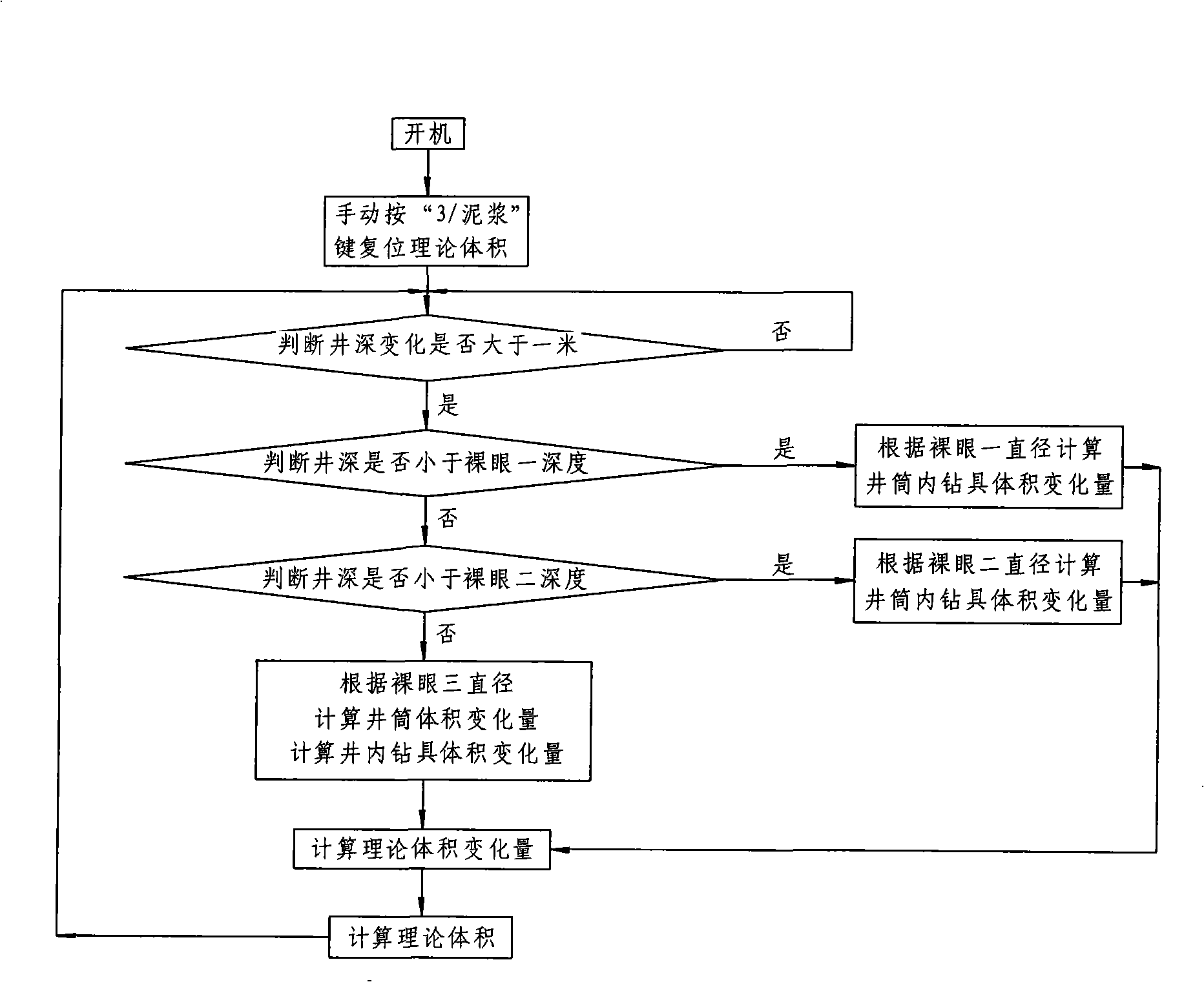

Image

Examples

Embodiment 1

[0096] At a certain moment, manually press the "3 / overflow" button on the monitor host to reset the current well depth, and the well depth is 1301.10m at this time 3 , the pool volumes in the four mud tanks are measured by the ultrasonic liquid level sensor sensor installed in each mud tank respectively: 39.5m 3 , 42.6m 3 , 35.8m 3 , 38.5m 3 , that is, the total pool volume at this time is 156.4m 3 , assigning this value as the current theoretical volume 0 , namely: theoretical volume 0 =156.4m 3 .

[0097] It can be seen from the depth of the open hole that the well depth of 1301.10m is less than the depth of the open hole 2 of 2100m. According to the formula:

[0098] Wellbore volume = cross-sectional area of open hole 1 × depth of open hole 1 + cross-sectional area of open hole 2 × (well depth - depth of open hole 1)

[0099] The calculation results are as follows:

[0100] Wellbore volume = π × (0.4 / 2) 2 ×215+π×(0.35 / 2) 2 ×(1301.10-215)

[0101] =123.68m 3...

Embodiment 2

[0117] At a certain moment, manually press the "3 / overflow" button on the monitor host to reset the current well depth, and the well depth is 3452.20m at this time 3 , the pool volumes in the four mud tanks are: 41.1m 3 , 44.2m 3 , 37.4m 3 , 39.9m 3 , that is, the total pool volume at this time is 162.6m 3 , which is given as the current theoretical volume k , the theoretical volume k Equal to 162.6m 3 .

[0118] At this time, the well depth of 3452.20m is less than the depth of 4000m in the open hole 3, according to the formula:

[0119] Wellbore volume = cross-sectional area of open hole 1 × depth of open hole 1 + cross-sectional area of open hole 2 × depth of open hole 2 + cross-sectional area of open hole 3 × (well depth - depth of open hole 2); the calculation results are as follows:

[0120] Wellbore volume = π × (0.4 / 2) 2 ×215+π×(0.35 / 2) 2 ×(2100-215)

[0121] +π×(0.25 / 2) 2 ×(3452.20-2100)

[0122] =251.28m 3

[0123] Drill volume = [π×(0.18 / 2) 2 -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com