Gas-turbine unit turbine guider link construction

A turbine guider and connecting structure technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of uncoordinated deformation, unstable installation, large deformation of the connecting structure, etc., and achieve reduced leakage, good gas sealing, Tight installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

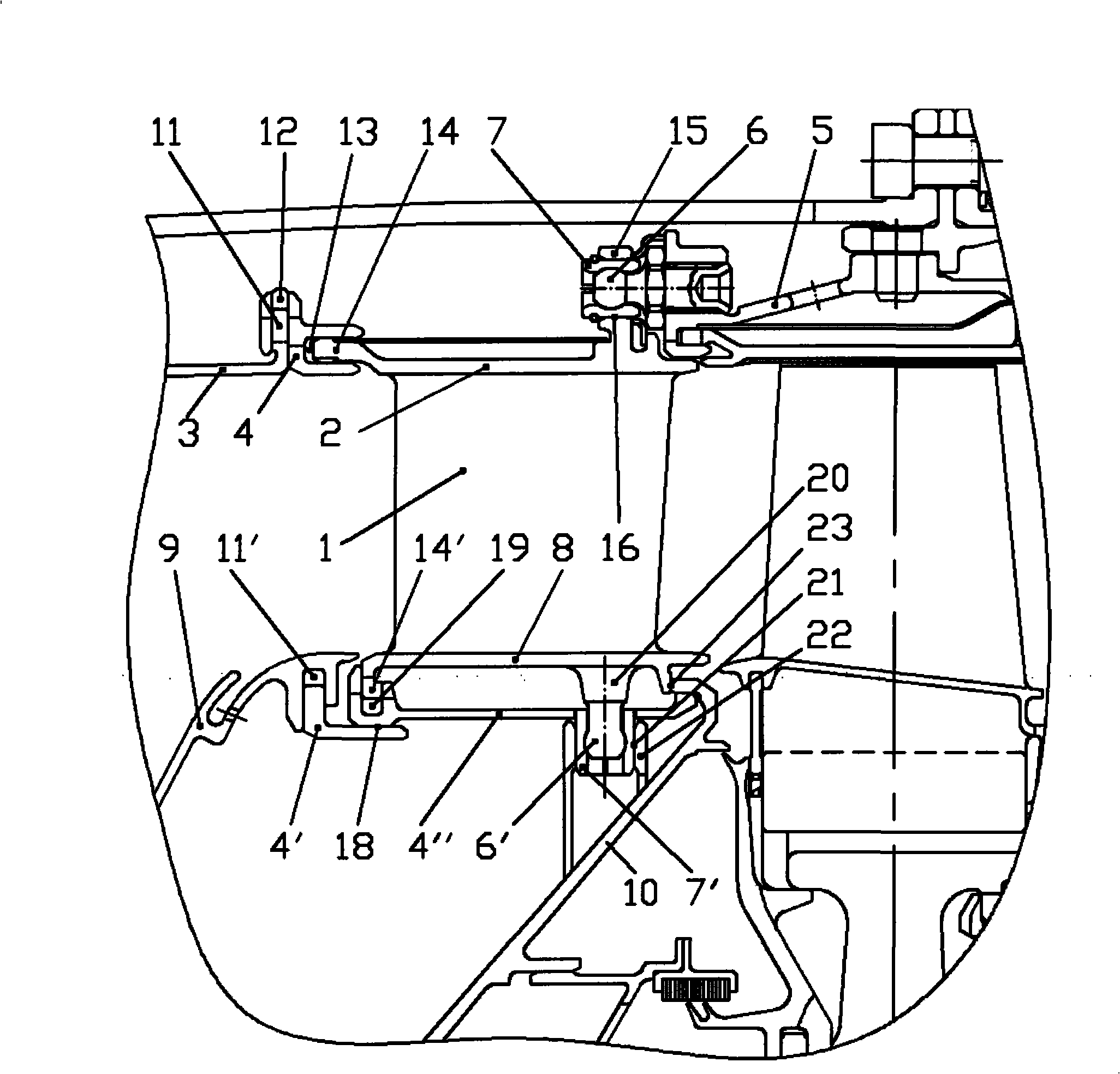

[0010] The gas turbine engine turbine guider connection structure of the present invention comprises the inner and outer edge plates 8, 2 of the connection guider 1, the combustion chamber and the outer case 9, 3, the mounting rings 4, 4`, 4``, the turbine inner , Outer casing 10,5, hinge 6,6 ' and sleeve pipe 7,7 '.

[0011] The radial groove 11 at the front part of the mounting ring 4 is connected with the flange 12 on the casing 3 outside the combustion chamber, and is constrained in the axial direction and free in the radial direction. The axial ring groove 13 at the rear part of the mounting ring 4 cooperates with the guide flange 14, free in the axial direction and constrained in the radial direction. In this way, the axial and radial directions between the guide 1 and the casing 3 outside the combustion chamber are free.

[0012] The axial positioning hole 16 on the lug 15 at the rear of the guider outer edge plate 2 is connected with the hinge 6 fixed on the outer cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com