Continuous heat supply phase-change energy storage defrosting system

A phase-change energy storage, non-interrupted technology, used in indirect heat exchangers, heat storage equipment, heat exchanger types, etc., can solve problems such as poor unit stability and reliability, slow defrosting speed, and affecting room comfort. , to achieve the effect of high energy utilization, improved comfort, and improved defrosting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

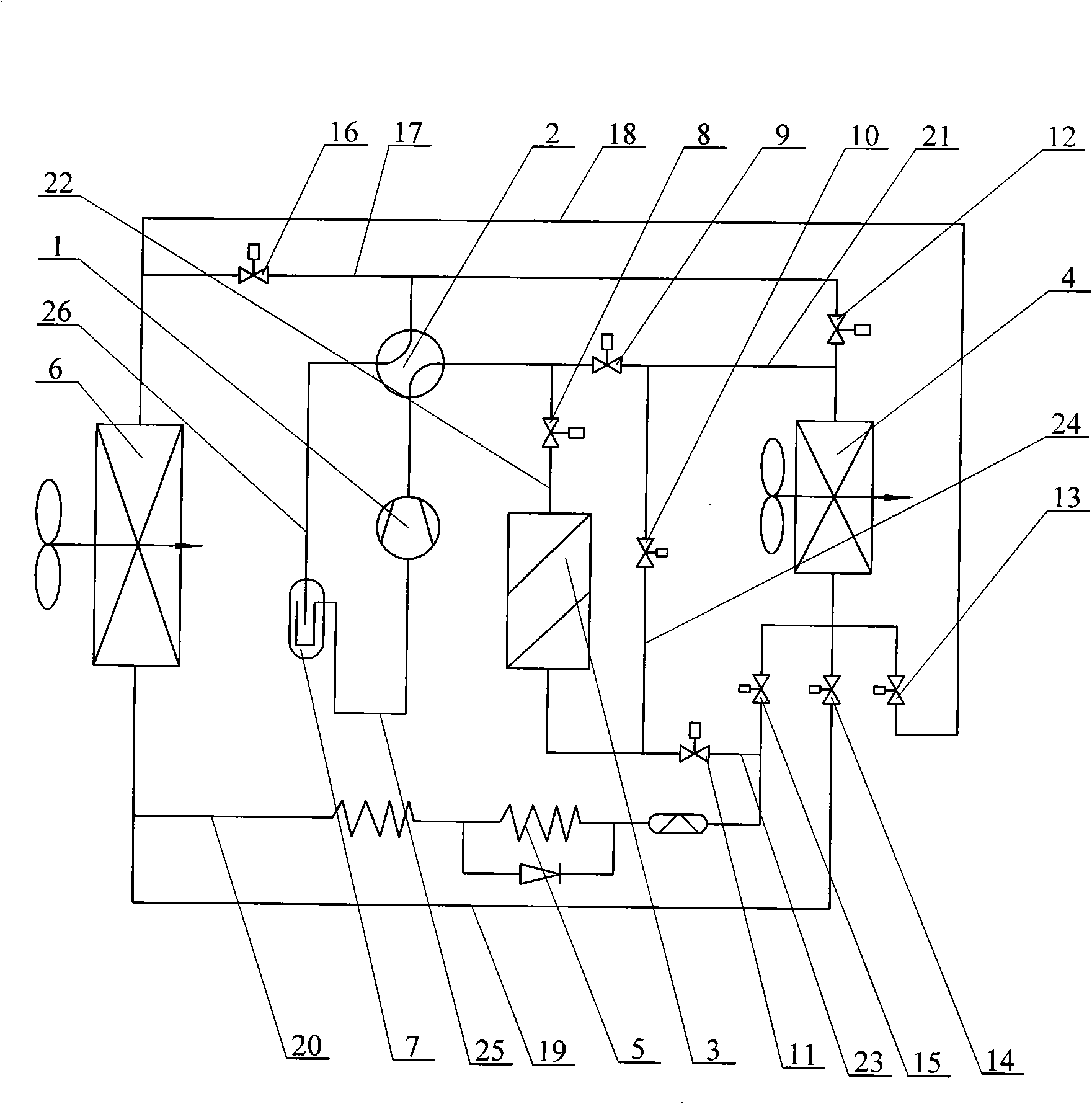

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment, the energy storage defrosting system of this embodiment includes a compressor 1, a four-way reversing valve 2, an indoor unit 4, a capillary tube 5, an outdoor unit 6, a gas-liquid separator 7, a phase change heat accumulator 3, First valve 8, second valve 9, third valve 10, fourth valve 11, fifth valve 12, sixth valve 13, seventh valve 14, eighth valve 15, ninth valve 16, first pipeline 17 , the second pipeline 18, the third pipeline 19, the fourth pipeline 20, the fifth pipeline 21, the sixth pipeline 22, the seventh pipeline 23 and the eighth pipeline 24; the input of the compressor 1 The end is connected with the output end of the gas-liquid separator 7, the output end of the compressor 1 is connected with the first interface of the four-way reversing valve 2, and the second interface of the four-way reversing valve 2 is connected with the first pipeline 17. connection, the two ends of the...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the energy storage defrosting system of this embodiment also includes a ninth pipeline 25; both ends of the ninth pipeline 25 are separated from the gas-liquid The output terminal of the device 7 is connected with the input terminal of the compressor 1 for convenient connection.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the energy storage defrosting system of this embodiment also includes a tenth pipeline 26; the two ends of the tenth pipeline 26 are separated from the gas-liquid The input end of the device 7 is connected with the third interface of the four-way reversing valve 2, which is convenient for connection.

[0015] The invention is a new system that organically combines air source heat pump technology and phase change energy storage technology based on the idea of energy time-space transfer. This system uses air source heat pump to extract heat from the air in winter and store it in the phase change heat accumulator. When defrosting is required, the stored heat is taken out for defrosting and heating for the room. The system operation mode can be divided into normal heating mode, heat storage mode and defrosting mode. Amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com