Interval adjusting construction of moving component

A technology of gap adjustment and moving parts, applied in the parts, instruments, casings and other directions of the instrument, it can solve the problems of not beautiful appearance, hard friction, uneven gap, etc., so as to reduce the possibility of hard friction and reduce the The effect of verticality and uniform gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

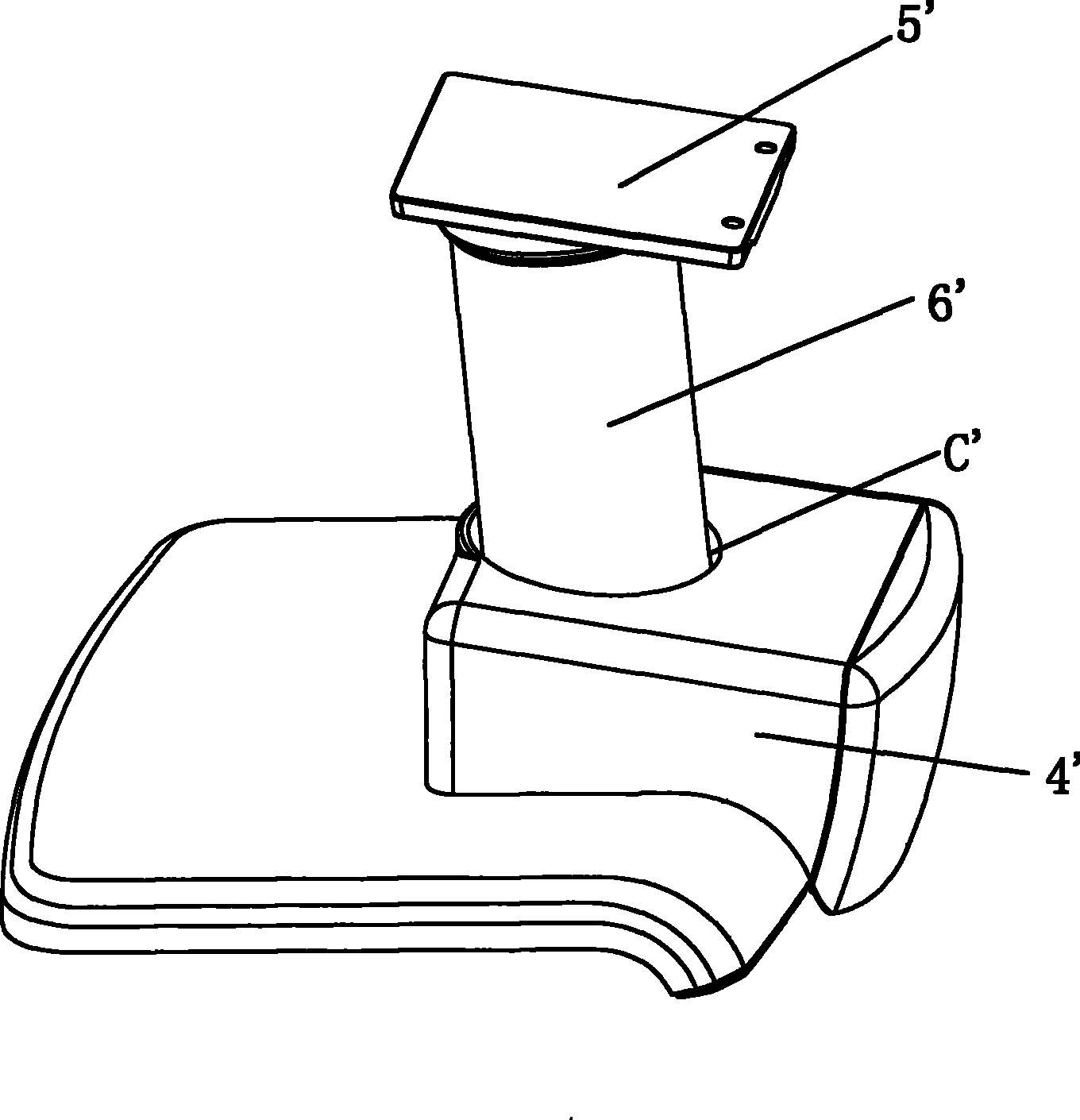

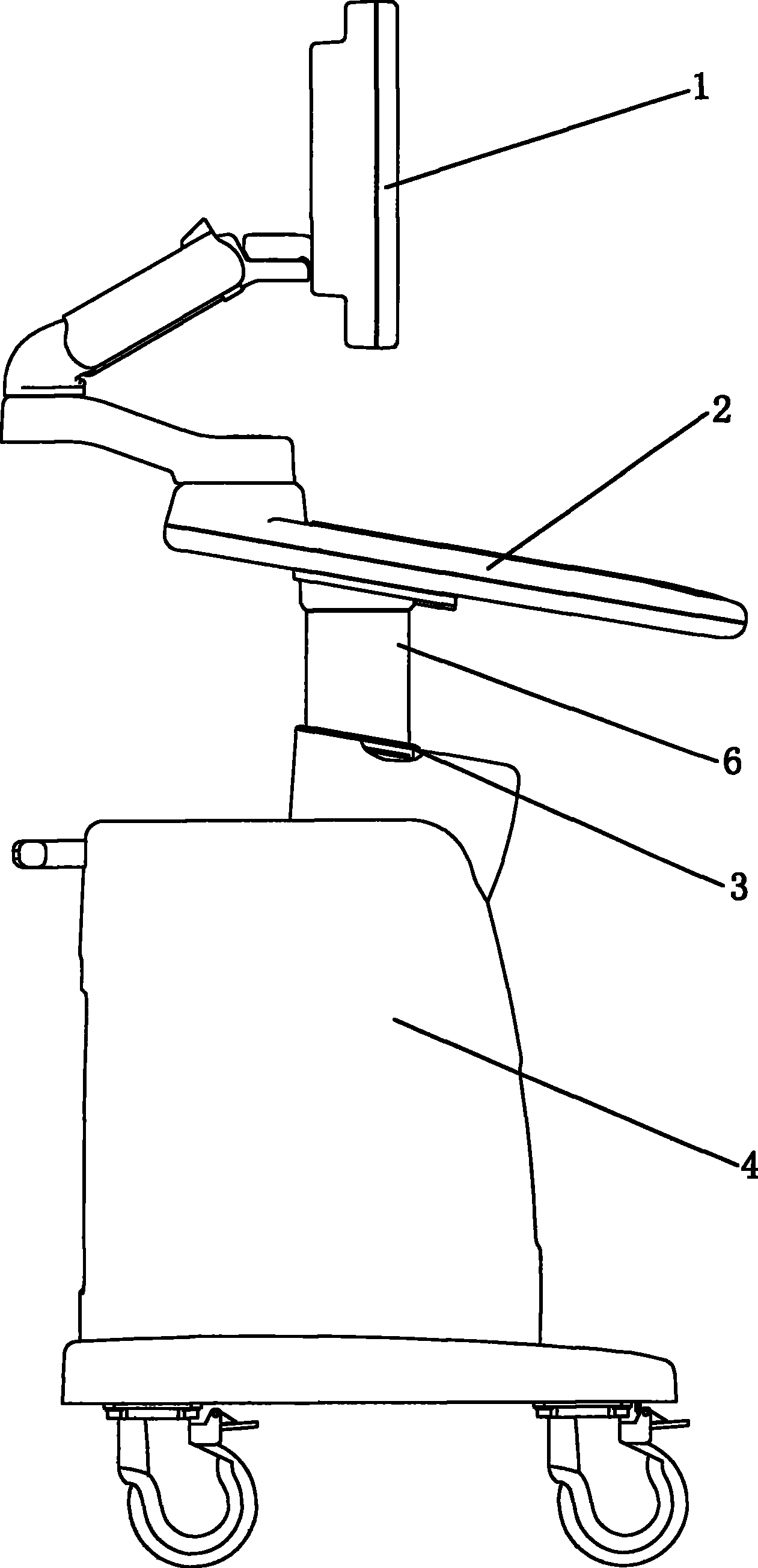

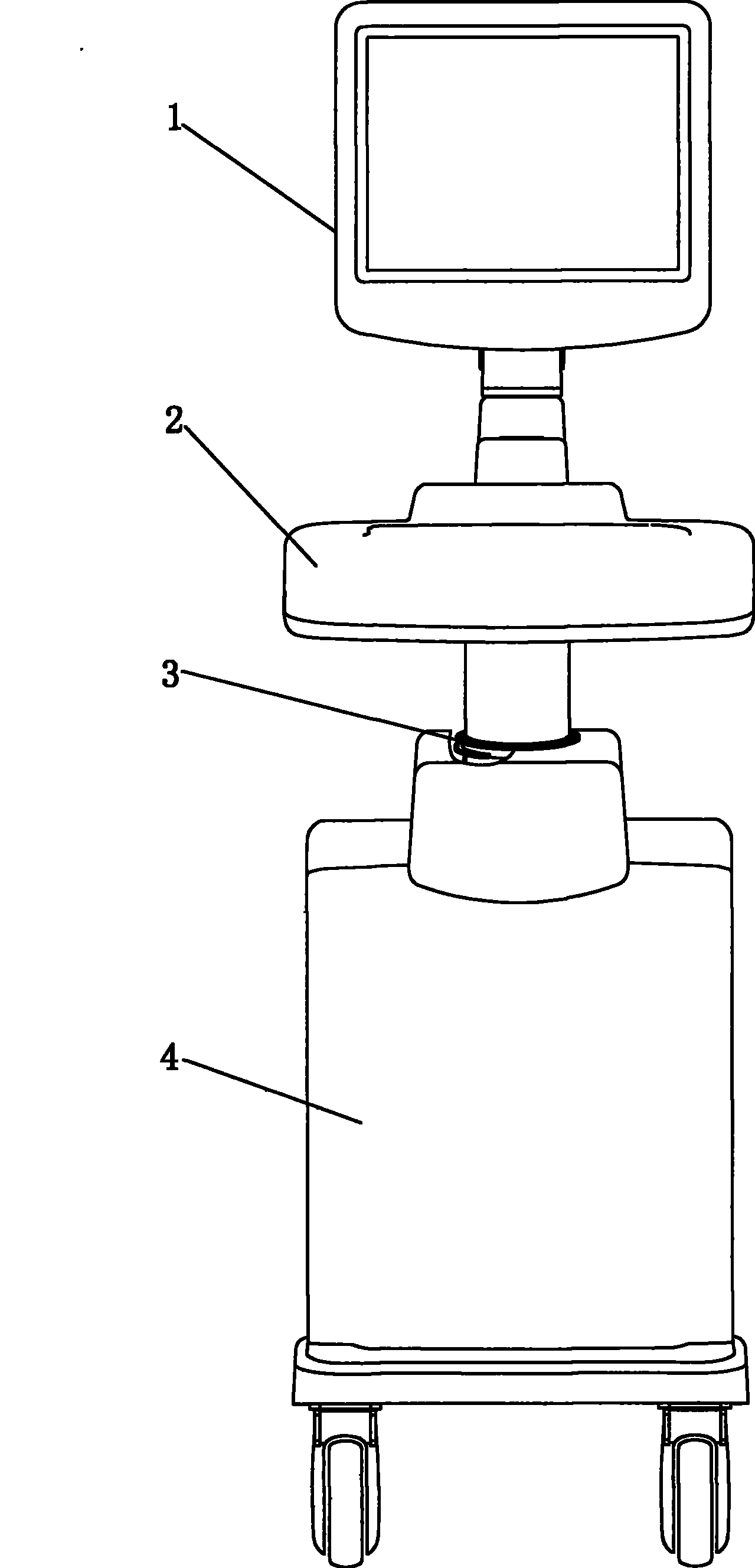

[0021] see Figure 2 to Figure 8 The gap adjustment structure of the moving parts in this embodiment includes a first part 4, a second part 6 and an adjustment ring 3. The first part has a mounting hole, and the adjustment ring is fitted into the mounting hole and covers the second part.

[0022] The first component 4 has a casing 41 , and the casing 41 has a first surface 411 , a second surface 412 and a mounting hole 413 passing through the first and second surfaces 411 , 412 . The second component 6 is a cylinder, which is inserted into the mounting hole 413 of the first component and can move axially relative to the first component 4 . The adjustment ring 3 is made of soft material, such as soft rubber, so that it can be deformed when extruded by external force. The section of the adjustment ring 3 is I-shaped, and the adjustment ring 3 has a body 31 , a first clamping edge 32 and a second clamping edge 33 . The main body 31 is cylindrical, with a through hole 311 axiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com