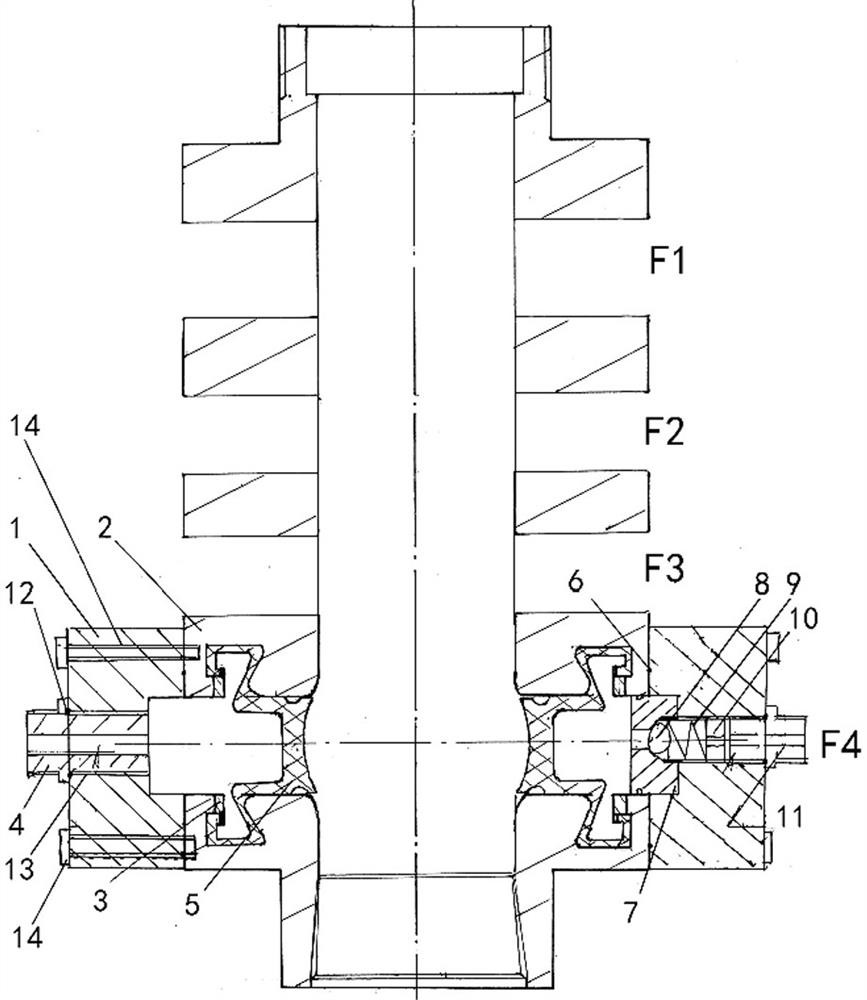

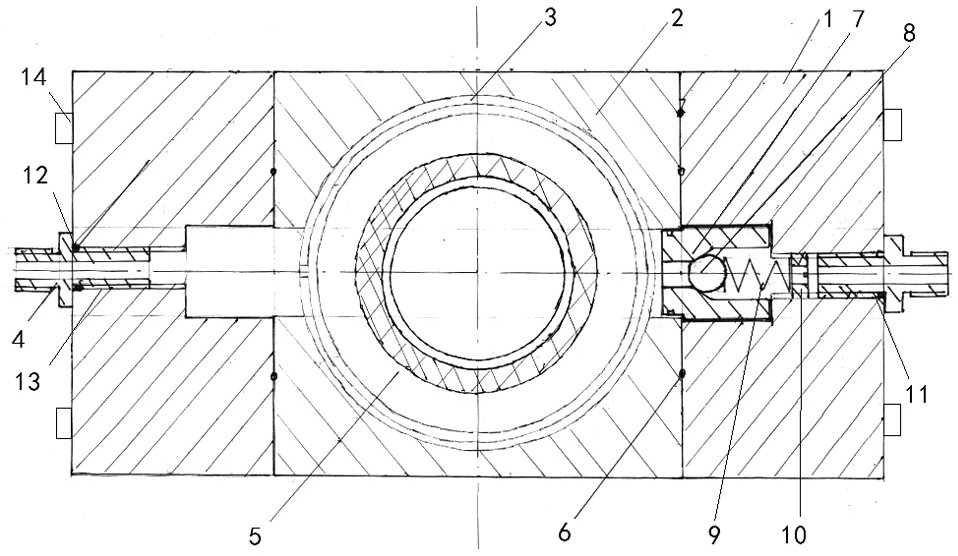

Coiled tubing four-gate blowout preventer

A technology of blowout preventer and four rams, applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as poor sealing, failure of semi-sealing device, failure, etc., to avoid man-made damage , prolong the service life, reduce the effect of hard friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

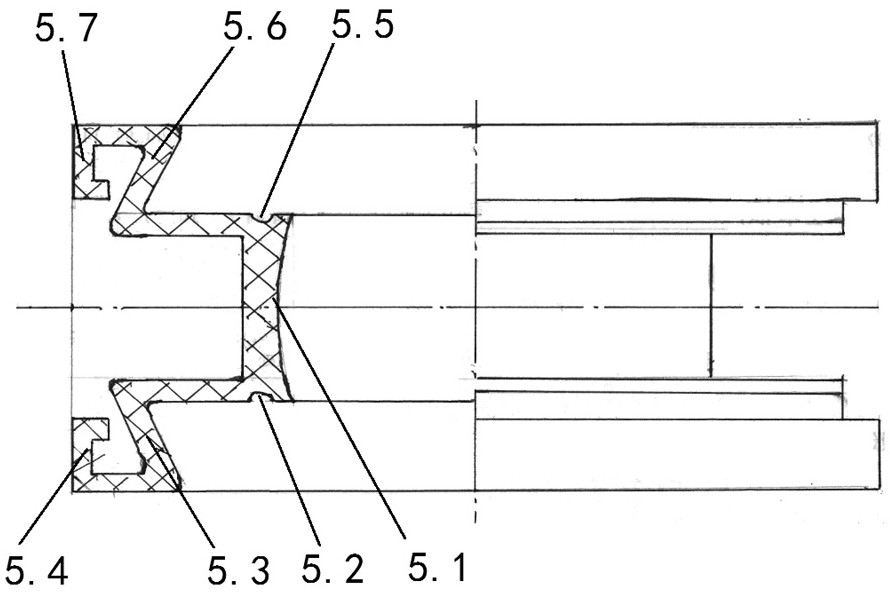

[0032] Embodiment 2, the difference from Embodiment 1 is: the section of the side of the setting expansion side (5.1) of the present invention in contact with the coiled tubing is an arc-shaped structure, and the section of the other side is a protrusion that is conducive to rebound Arc structure.

[0033] The method of use is the same as that of Example 1, the difference is: as the hydraulic pressure rises, the setting expansion side (5.1) expands in one direction under the action of pressure to form a cup seal structure, so that it is tight and continuous The outer wall of the tubing forms a seal; while the cross-section of the side in contact with the coiled tubing is an arc-shaped structure, the opposite direction forms a raised bowl-bottom shape.

Embodiment 3

[0034] Embodiment 3, the difference from Embodiments 1 and 2 is that the setting expansion side (5.1) of the present invention is a three-stage structure, and the section of the side in contact with the coiled tubing is an arc structure, a planar structure and an arc shape The structure consists of three sections, and the middle section is a planar structure.

[0035] In this way, the plane structure in the middle is better combined with the outer wall of the coiled tubing, forming a larger sealing surface and a longer-lasting sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com