A clutch wear indicator plate structure

An indicator plate and clutch technology, applied in the field of clutch wear indicator plate structure, can solve the problems of easy fatigue failure, easy corrosion, and vehicle vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

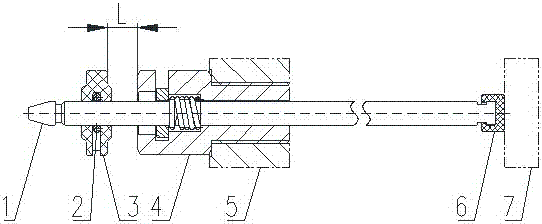

[0017] Such as figure 1 As shown, the present invention is a clutch wear indicator plate structure, including a straight rod 1, the straight rod 1 is made of stainless steel, the axis of the straight rod 1 is in the same direction as the axis of the clutch booster cylinder, and the two ends of the straight rod 1 are respectively located in the cavity of the booster cylinder Inside and outside, the end of the straight rod 1 located inside the cavity of the booster cylinder is located at the limit point of the movement position of the booster cylinder piston 7 under the touch of the booster cylinder piston 7 .

[0018] The end of the straight rod 1 located outside the booster cylinder cavity is provided with an indicator sheet 3, specifically, the end of the straight rod 1 located outside the booster cylinder cavity is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com