A bearing wear detection device and detection method in shielded pump

A technology of a bearing wear detection device, which is applied in the field of bearing wear detection devices in shielded pumps, bearing wear detection and detection devices in shielded pumps, can solve the problems of complex structure and operation, poor detection reliability, etc., and achieve simple structure and improved reliability performance, sensitivity enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

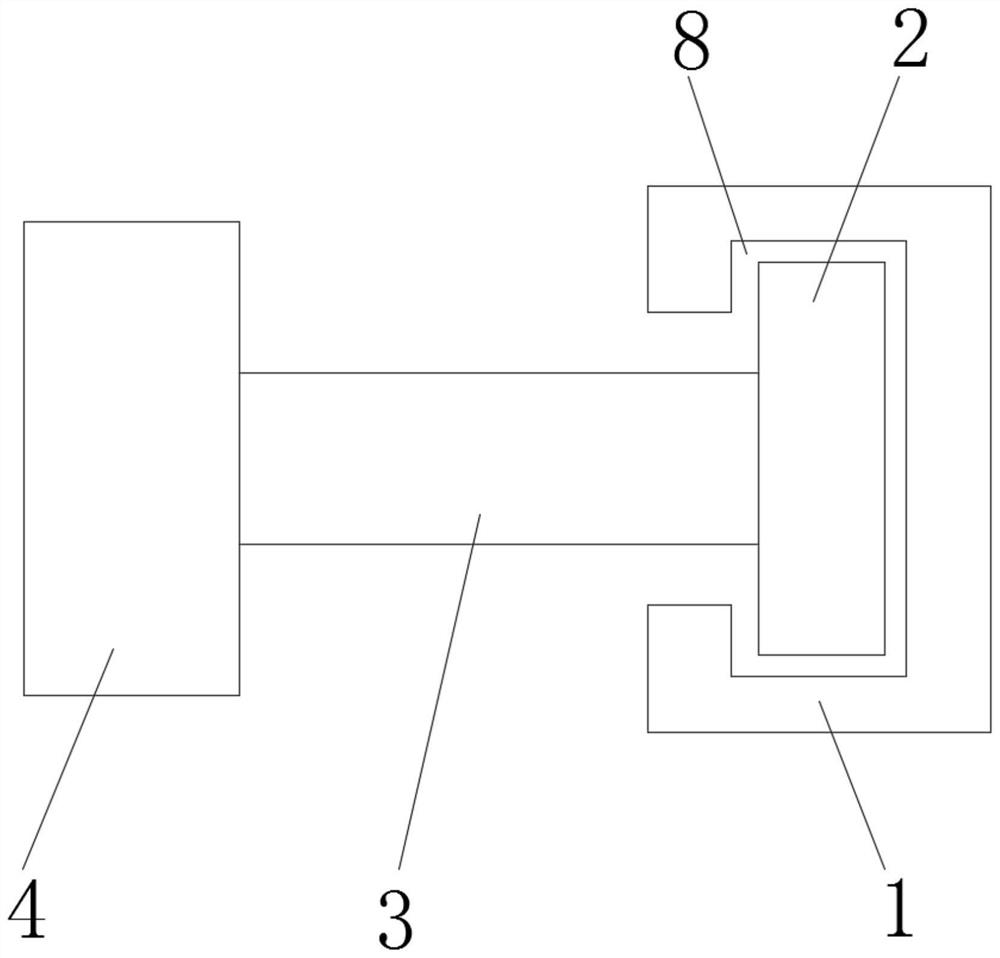

[0042] see figure 1 as well as figure 2 , this embodiment provides a bearing wear detection device in a canned pump, the detection device is used to detect the amount of wear of the bearing. In this embodiment, the bearing is the rotating shaft bearing in the canned pump, while in other embodiments, the bearing can be other bearings. Wherein, the detection device includes a connecting piece 1 , a detection probe 2 , a transmission tube 3 and a detection mechanism 4 .

[0043] The connecting piece 1 is sleeved on the rotor tail of the bearing, and the end away from the bearing is provided with a groove 8 arranged coaxially with the rotor. In this embodiment, the connecting piece 1 is an end nut. One end of the end nut is a closed end, and the other end is provided with a groove 8 . The groove 8 is divided into two sections, which are arranged in the middle and the end of the end nut respectively. When the bearing wears radially, the rotor will move forward or backward and...

Embodiment 2

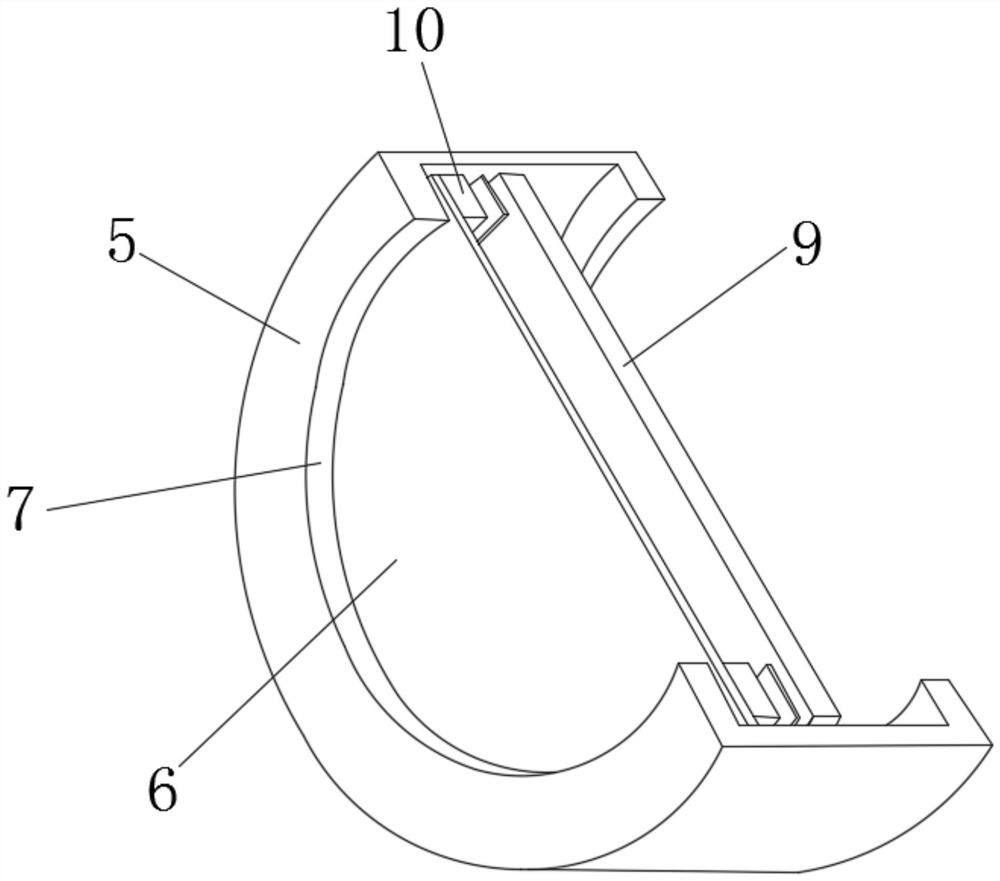

[0055] This embodiment provides a bearing wear detection device in a canned pump, which is similar to the detection device in Embodiment 1, except that the structure of the displacement sensing unit is different. In this embodiment, the displacement sensing unit has coils and magnets in addition to the diaphragm 6 . The coil is connected to the diaphragm 6 and the magnet is installed in the detection case 5 . Wherein, the diaphragm 6, the coil and the magnet form a moving coil structure. Vibration of the diaphragm 6 changes the magnetic flux generated by the magnet in the coil, and causes the coil to generate a current signal that is positively correlated with the radial wear amount, and the current signal is used as detection signal 1 or detection signal 2.

[0056] The displacement sensing unit in this embodiment can form a moving coil structure through the diaphragm 6, the coil and the magnet. During the vibration of the diaphragm 6, the magnetic flux of the magnet in the ...

Embodiment 3

[0058] This embodiment provides a bearing wear detection device in a canned pump, which is similar to the detection device in Embodiment 1, except that the displacement sensing unit is a pneumatic sensor. The pneumatic sensor is used to sense the vibration of the resonant cavity, and generates a detection signal 1 according to the vibration deformation amount 1, and generates a detection signal 2 according to the vibration deformation amount 2. Since the resonant cavity will vibrate when the rotor vibrates, the pneumatic sensor can directly sense this vibration and generate a corresponding detection signal, so that the wear of the bearing can be detected, which is convenient for the analysis and treatment of the wear of the bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com