Real-time monitoring device and method for comprehensive gear abrasion condition of winch hoist

A technology of real-time monitoring and hoist, applied in the field of hoist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

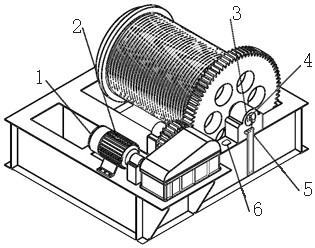

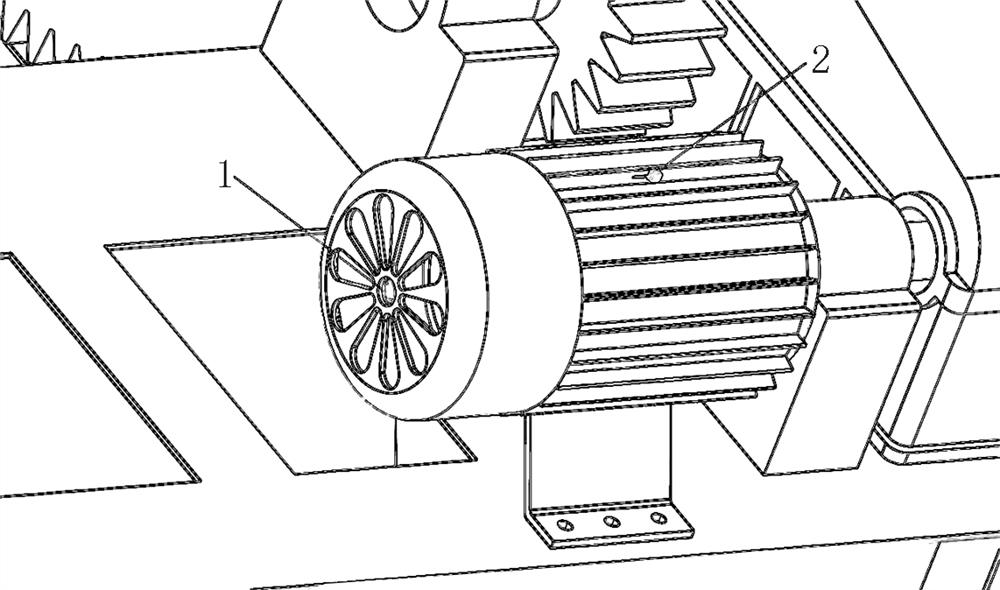

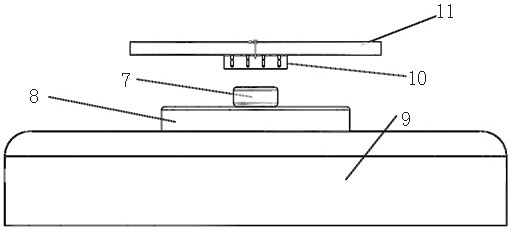

[0027] The following is attached figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The structure and working process of the present invention are described in detail.

[0028] figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Attached figure number:

[0029] 1 is the motor angular velocity rotary encoder sensor, 2 is the motor vibration sensor, 3 is the end of the reel shaft, 4 is the vibration sensor at the end of the reel shaft, 5 is the follower cable system components at the end of the reel shaft, 6 is the controller, 7 is a pie-shaped permanent magnet, 8 is the end of the motor rotating shaft, 9 is the motor casing, 10 is the angular velocity rotary encoder chip, 11 is the PCB circuit board, 12 is the shell, 13 is the fixed seat, 14 is the fixed pulley, 15 is Gravity pulley, 16 is rotating shaft, and 17 is lead wire 17.

[0030] A real-time monitoring device for the comprehensive wear condition of hoist hoist gears, such as Figure 1 to Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com