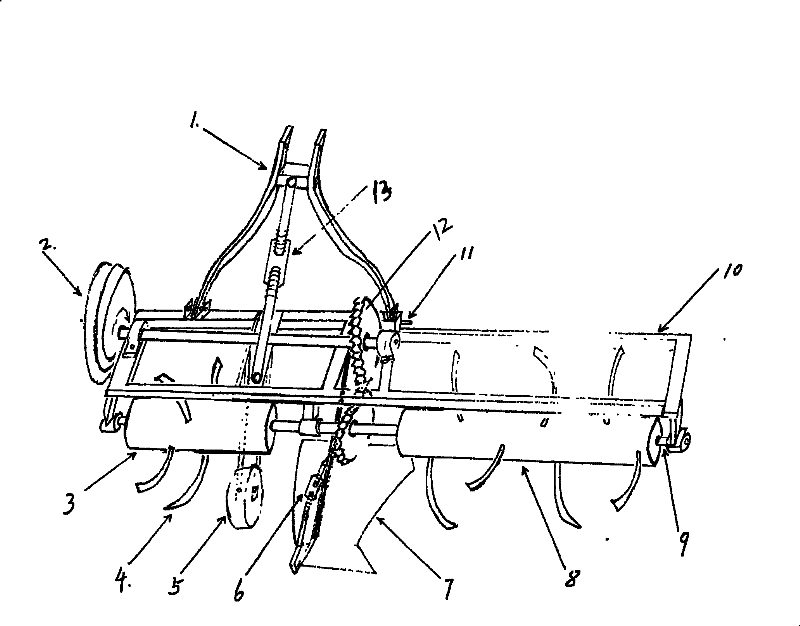

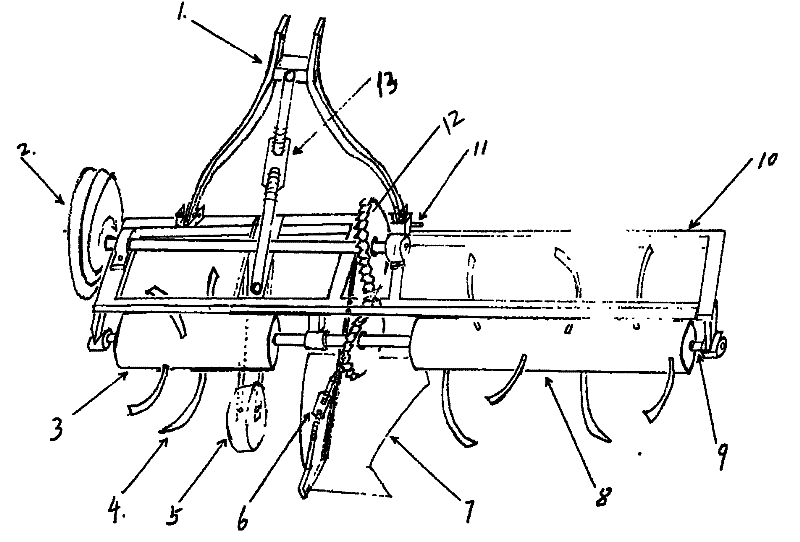

Two-stage crushing combined furrowing and harrowing machine

A secondary crushing and tillage harrow technology, which is applied in the field of agricultural machinery, can solve the problems of unfavorable agricultural production efficiency, low soil crushing degree, poor physical and chemical properties, etc., and achieve good farming effect, high soil fragmentation degree, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings. Connect the product of the present invention to the lifting device of the tractor, adjust the lifting of the whole machine through the control of the lifting device of the tractor, and adjust the plow surface installed behind the longitudinal beam installed in the middle part of the frame 10 and perpendicular to the frame 10 The entry angle adjustment device 6 and the adjustment rod 13 adjust the entry angle of the plow surface. Driven by the tractor, the tripod 1 and the connecting shaft 11 are fixed and connected with the universal joint on the tractor and drive the whole machine forward. The wheel 5 is supported at the bottom, and the transmission wheel 2 connected by the transmission belt on one axis of the tractor drives the other transmission gear 12, and the transmission gear 12 drives the gear on the horizontal shaft 9 meshed with it to rotate 12, thereby driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com