Spherical-surface journal spring

An axle box spring, spherical technology, applied in axle box installation, non-rotational vibration suppression and other directions, can solve problems such as small vertical deflection, and achieve the effects of weight reduction, reliability and maintenance-free, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

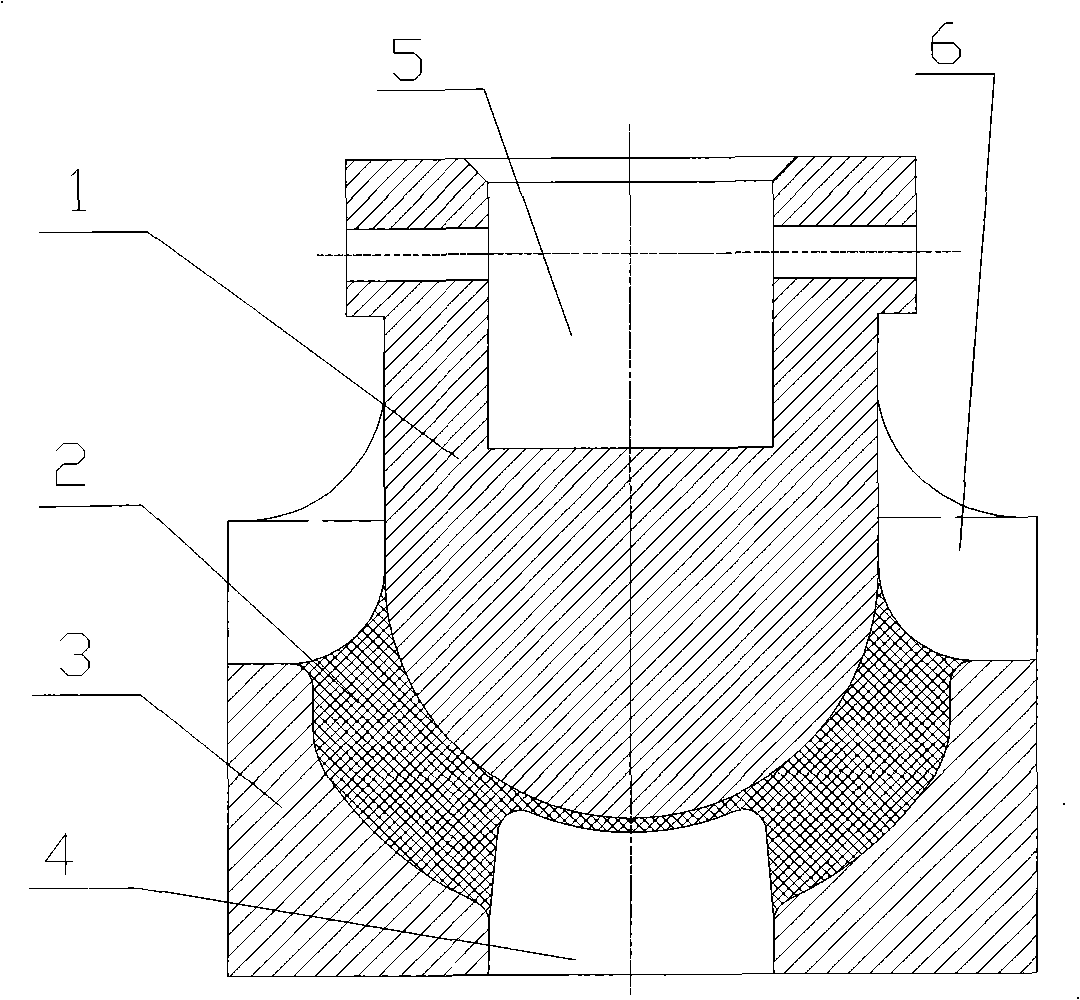

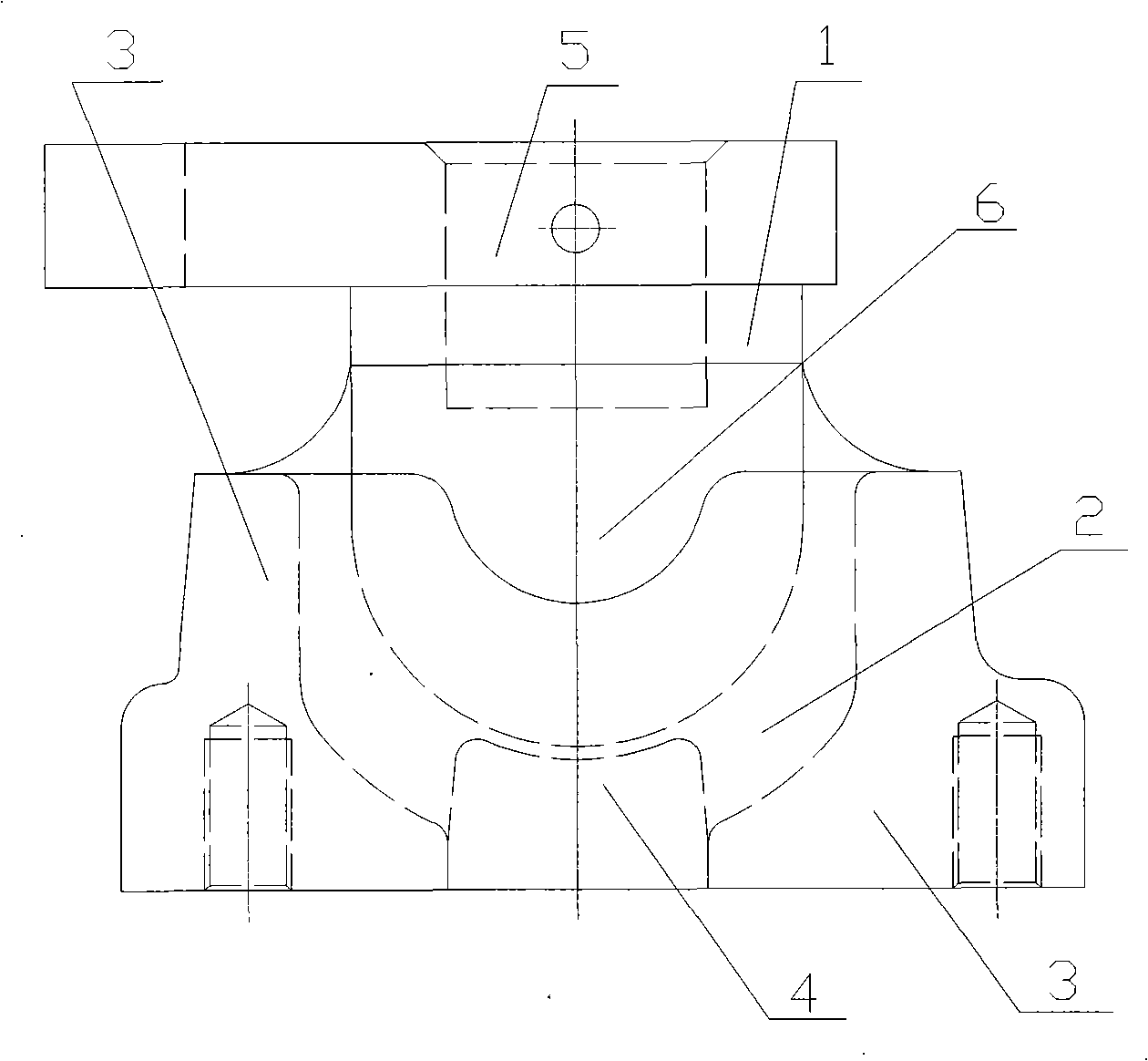

[0010] The accompanying drawings show an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0011] It can be seen from the drawings that the present invention is an axle box spring, which includes a mandrel 1; a rubber body 2; and a base 3. The rubber body 2 is vulcanized and bonded to the mandrel 1 and the base 3 up and down, respectively. It is characterized in that the rubber-metal composite axle box spring is a spherical axle box spring, and the rubber body 2 is a spherical compound shape body combining a spherical surface and a columnar shape. Among them, the lower part of the rubber body 2 is a spherical body, the side of the rubber body 2 is a columnar body, and the spherical body and the columnar body are smoothly transitioned and connected. There is a circular notch 4 in the lower part of the spherical shape of the rubber body, but a spherical rubber layer matching the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com