Surface cloth seamless production method for mold cup bra with self fabric embroidery on cup border

A bust surface and original cloth technology, which is applied in the direction of fabric surface trimming, clothing, textiles and papermaking, etc., can solve the problems affecting the appearance of the mold cup bust and the lack of elasticity in embroidery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following is the best embodiment of the face cloth seamless manufacturing method of the molded cup bust with the original cloth embroidered on the edge of the cup according to the present invention, which does not limit the protection scope of the present invention.

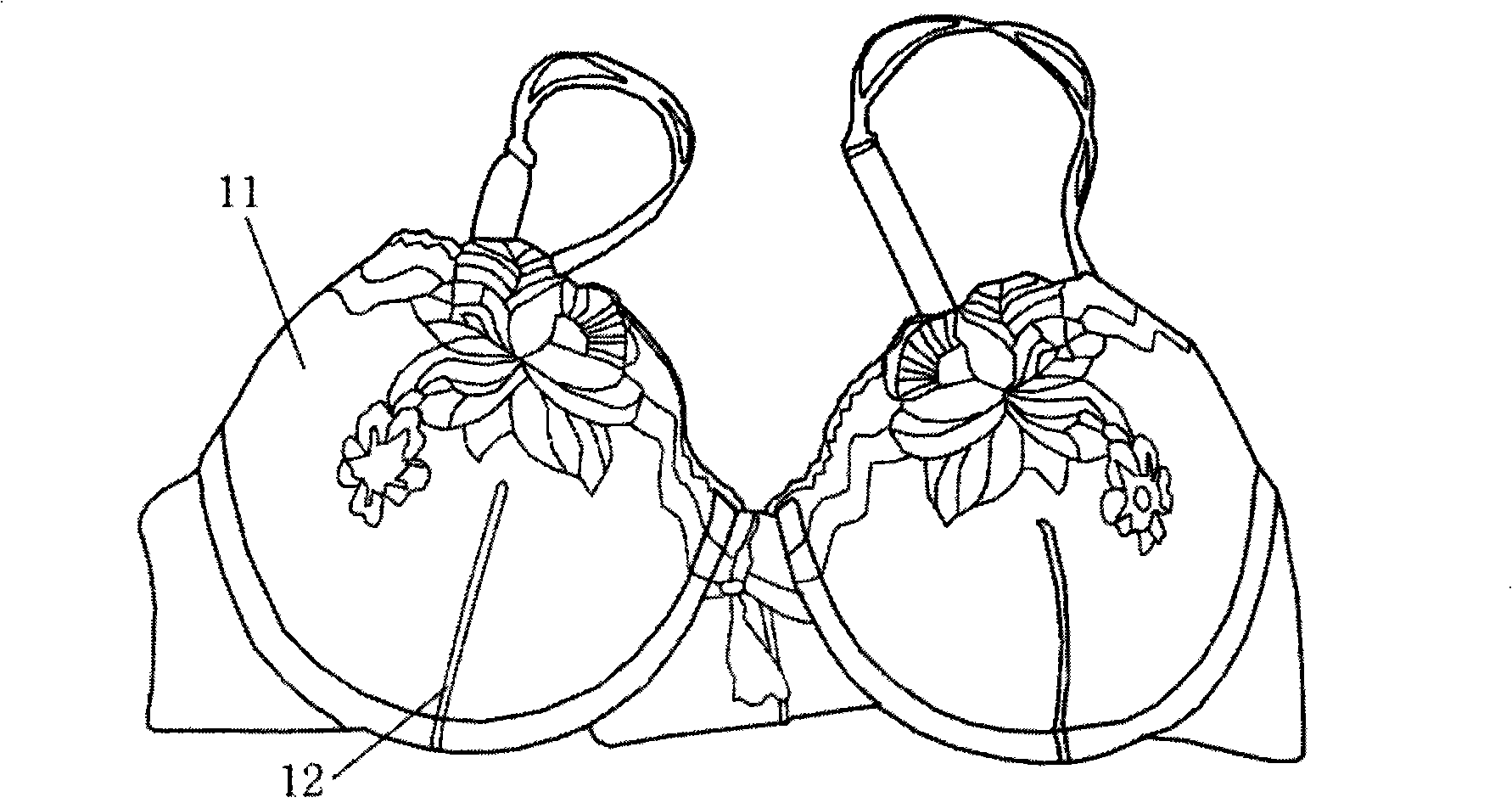

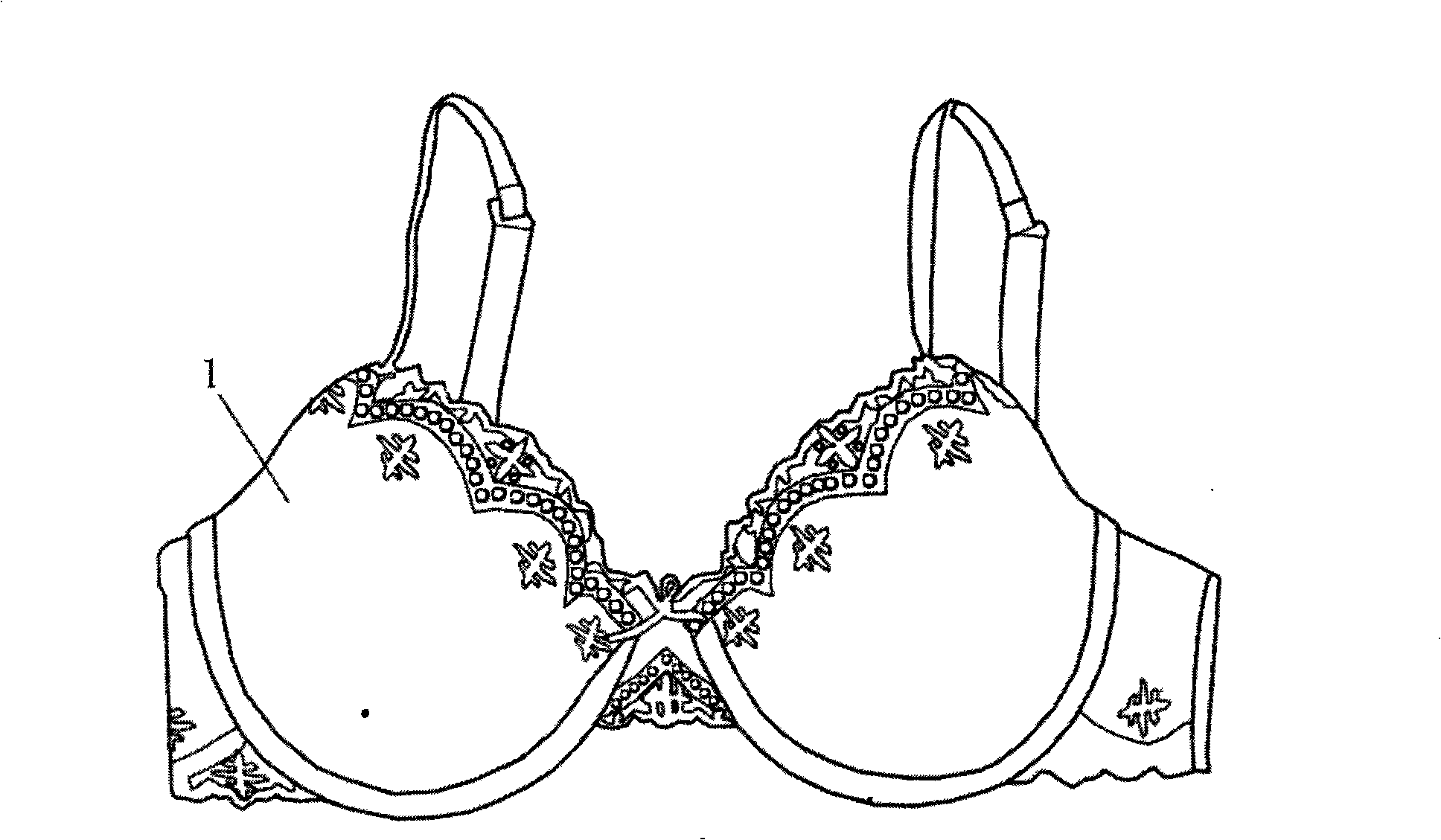

[0013] refer to figure 2 , image 3 , Figure 4 , Figure 5 A method for seamlessly fabricating a molded cup bust with original cloth embroidery on the edge of the cup is provided, comprising the following steps:

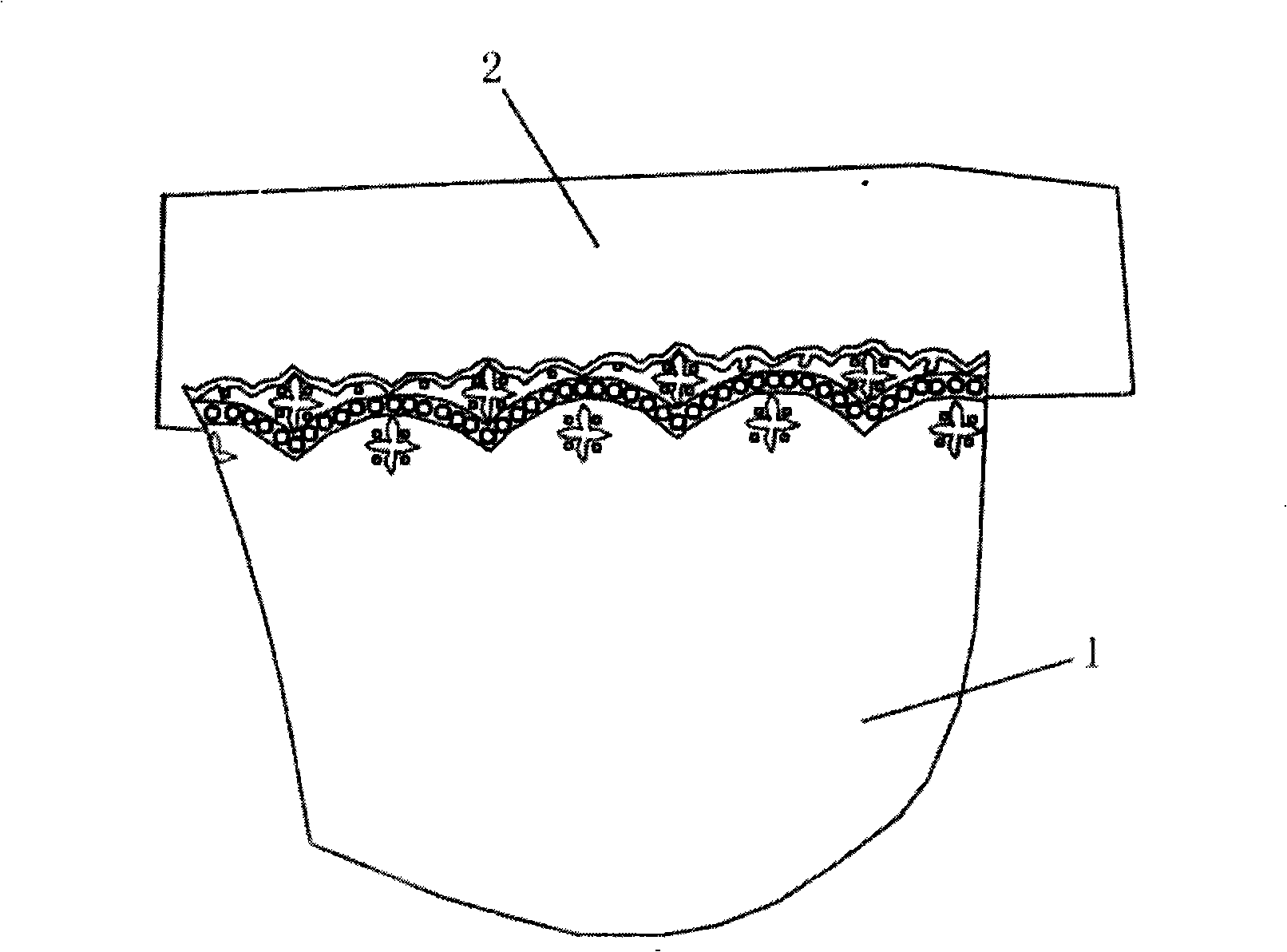

[0014] A. Cutting the native cloth with lace into the bust face cloth 1 of required size;

[0015] B, sew a cloth strip 2 on the lace side of the bust face cloth 1;

[0016] C, a gasket 5 is set at the die head opening 4 on the lower die 3 of the bullet die machine, the thickness of the gasket 5 is equal to the thickness of the cloth strip 2, and the gasket 5 has the same shape as the die head opening 4 at the die head opening 4. The recess corresponding to the die opening 4;

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com