Compound sweetener applied sour beverages and preparation method of sweetener

A technology for compound sweeteners and acidic beverages, applied in the field of food additives, can solve the problems that it is difficult to ensure that the main sweetener sucralose is dispersed evenly, affects the quality of compound sweetener products, and high power consumption of machinery and equipment, and achieves The effect of shortening processing cycle, saving power consumption and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

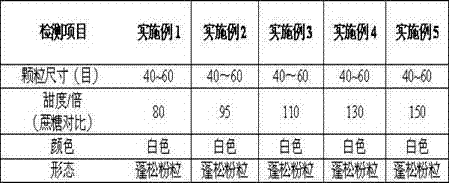

Examples

preparation example Construction

[0023] The preparation process of the compound sweetener is as follows: first put sucralose and glucose accounting for 80-90% of the total amount into a multi-dimensional mixer, mix for 30-40 minutes at a rate of 800-1000 rpm, and control the particle size of the mixed material at 80~130 mesh, get the mixed material of sucralose and glucose; then mix maltodextrin, sclareolactone, 2-acetylpyrrole, emulsifier, remaining glucose and deionized water to form a stable Emulsion; put the obtained mixed material into the spray fluidized bed equipment, make the mixed material enter the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerate the flow from bottom to top, and apply negative pressure to the upper part of the sprayed fluidized bed The pressure is vibrated from top to bottom to make the mixed material boil up and down in the fluidized bed. The air inlet temperature of the fluidized bed is controlled at 40~90°C to form fine powdered suga...

Embodiment 1

[0026] (1) Put 13.33 kg of sucralose and 70.41 kg of glucose into a multidimensional mixer, control the number of stages of the multidimensional mixer to 1000 rpm, and mix for 35 minutes to obtain a mixture of sucralose and glucose with a particle size of 80-130 mesh between;

[0027] (2) Mix 3 kg of maltodextrin, 0.04 kg of sclareolactone, 0.02 kg of 2-acetylpyrrole, 0.2 kg of emulsifier Span, and 13 kg of remaining glucose with deionized water, heat up and stir to dissolve, and obtain a stable lotion;

[0028] (3) Put the mixed material obtained in step (1) into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerates from bottom to top, and the sprayed fluidized bed Negative pressure is applied to the upper part of the fluidized bed to vibrate from top to bottom to make the mixed material boil up and down in the fluidized bed to form fine powdered sugar particl...

Embodiment 2

[0030](1) Put 15.83 kg of sucralose and 68.24 kg of glucose into a multidimensional mixer, control the number of stages of the multidimensional mixer to 1000 rpm, and mix for 35 minutes to obtain a mixture of sucralose and glucose with a particle size of 80 to 130 mesh between;

[0031] (2) Mix 3.5 kg of maltodextrin, 0.05 kg of sclareolactone, 0.03 kg of 2-acetylpyrrole, 0.25 kg of emulsifier Span, and 12.1 kg of remaining glucose with deionized water, heat up and stir to dissolve, and obtain a stable lotion;

[0032] (3) Put the mixed material obtained in step (1) into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerates from bottom to top, and the sprayed fluidized bed Negative pressure is applied to the upper part of the fluidized bed to vibrate from top to bottom to make the mixed material boil up and down in the fluidized bed to form fine powdered sugar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com