Split joint type plaster slab component and method for mounting in container as decoration

A gypsum board and splicing technology, which is applied to the structural field of spliced gypsum board components, can solve the problems of easy cracks on the surface, affecting the scope of use, and long manufacturing period, and achieves good waterproof performance, simple and fast installation method, and sound insulation performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

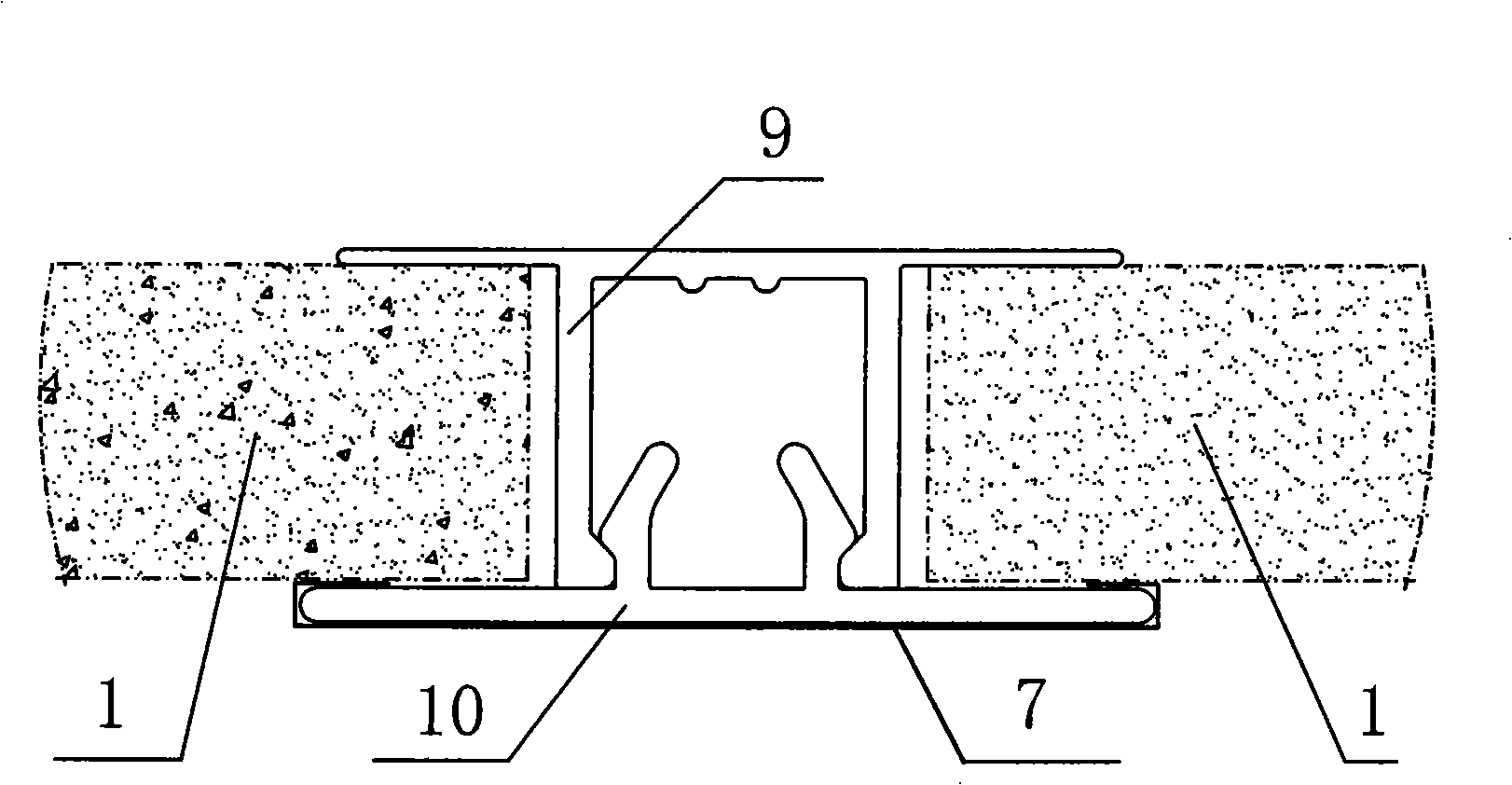

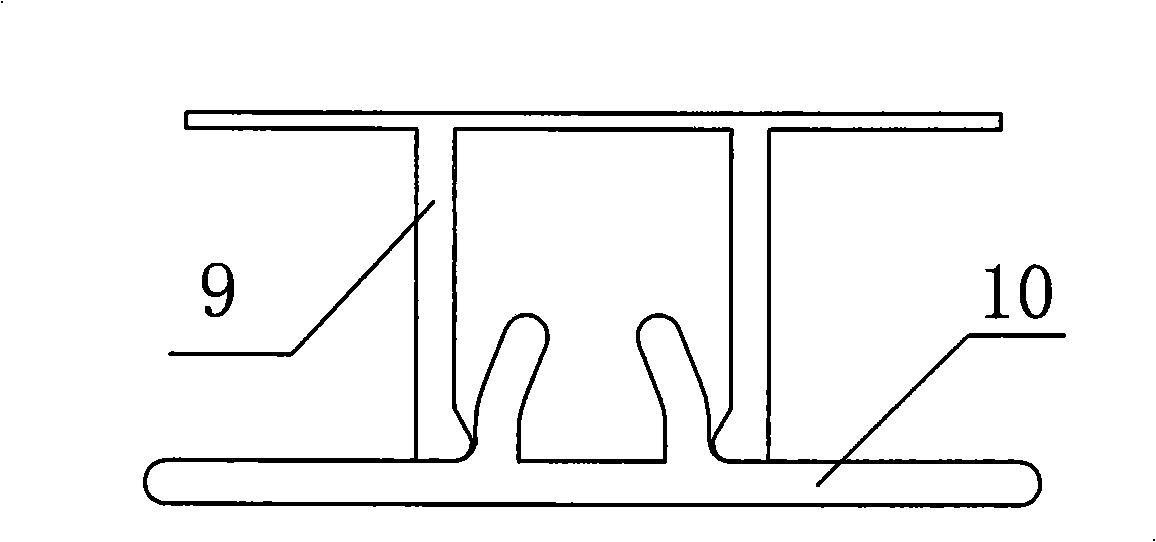

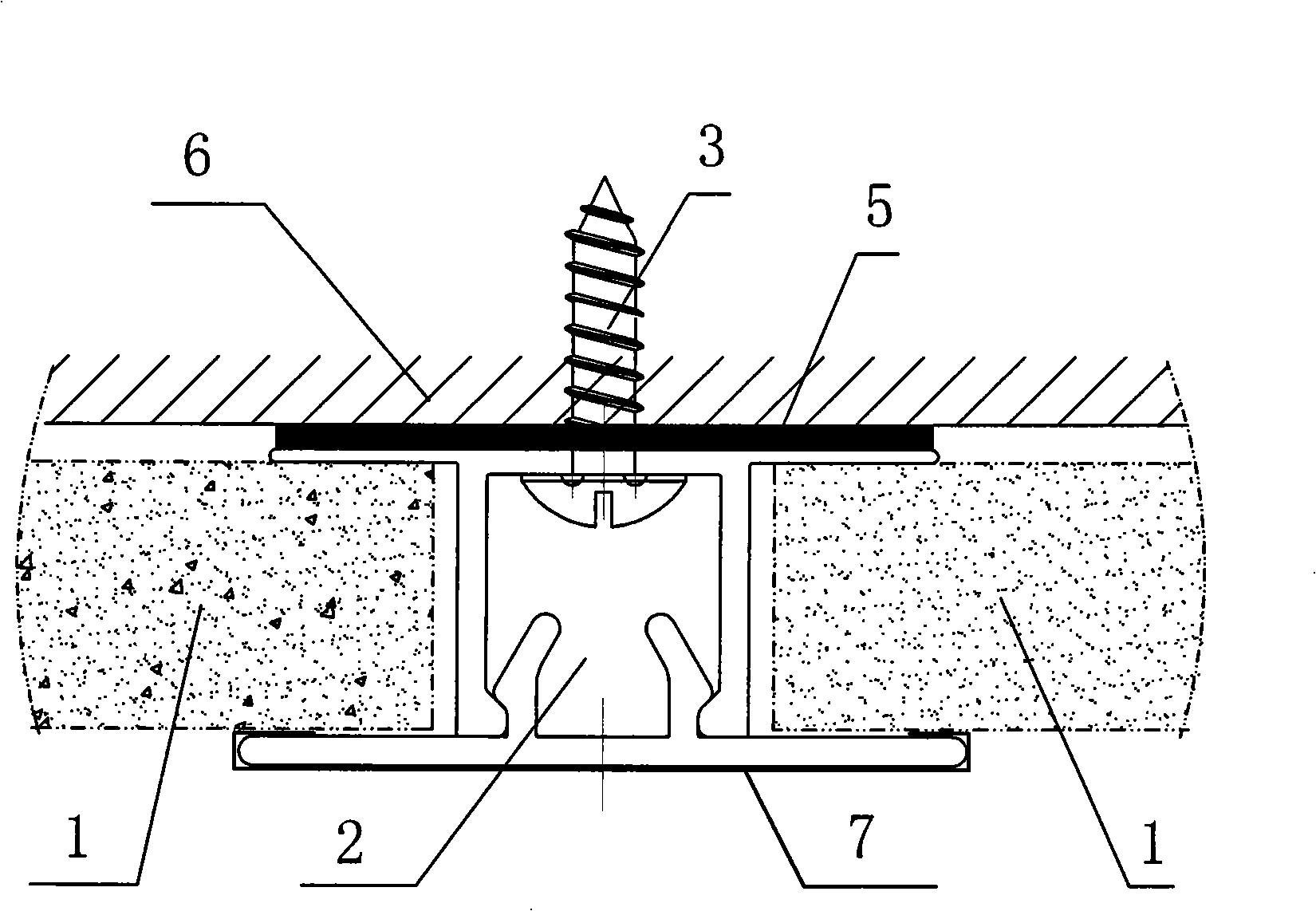

[0031] Such as figure 1 As shown, the film-coated gypsum board 1 formed by covering the surface of the paper-faced gypsum board with PVC film is installed and connected by the aluminum profile buckle 2 composed of the base 9 and the panel 10 to form a spliced gypsum board assembly.

[0032] Such as figure 1 , figure 2 , image 3 As shown, the spliced gypsum board assembly is used for the installation method of the container inner wall and ceiling system, and the steps are as follows:

[0033] ① Check and repair the flatness of the inner wall of the box and the installation surface of the ceiling system, so that the installation surface meets the relatively flat requirements for installing spliced gypsum board components;

[0034] ②An elastic shock-absorbing gasket 5 with a shock-absorbing function is pasted on the inner wall of the box and the ceiling system corresponding to the aluminum profile buckle in the spliced gypsum board assembly, and rubber gaskets and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com