Current transformer detection method and system

A detection method and detection system technology, which can be applied to instruments, measuring electricity, measuring devices, etc., and can solve problems such as component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The invention provides a converter detection method, which can find hidden troubles as much as possible before connecting a high-voltage power supply, and reduces the risk of high-voltage detection.

[0051] In order to more clearly illustrate the detection method of the current transformer of the present invention, it will be described in detail below in conjunction with specific drawings.

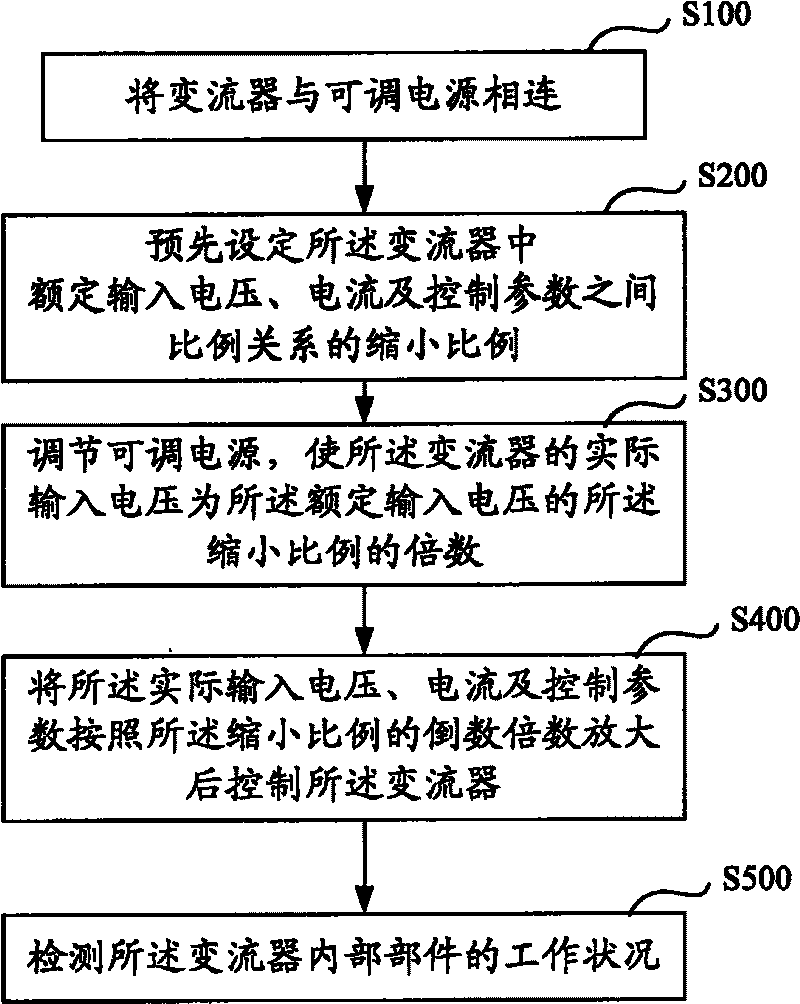

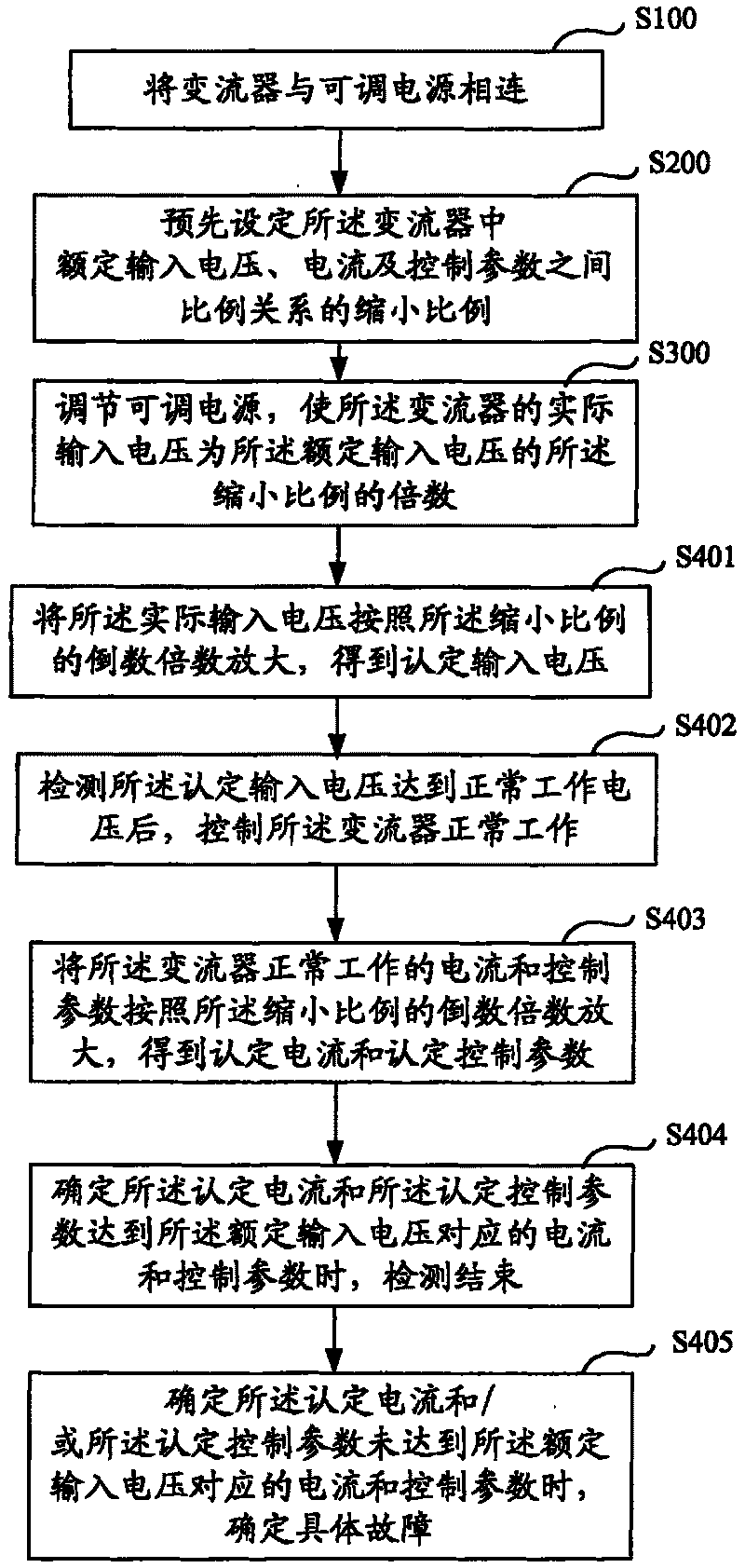

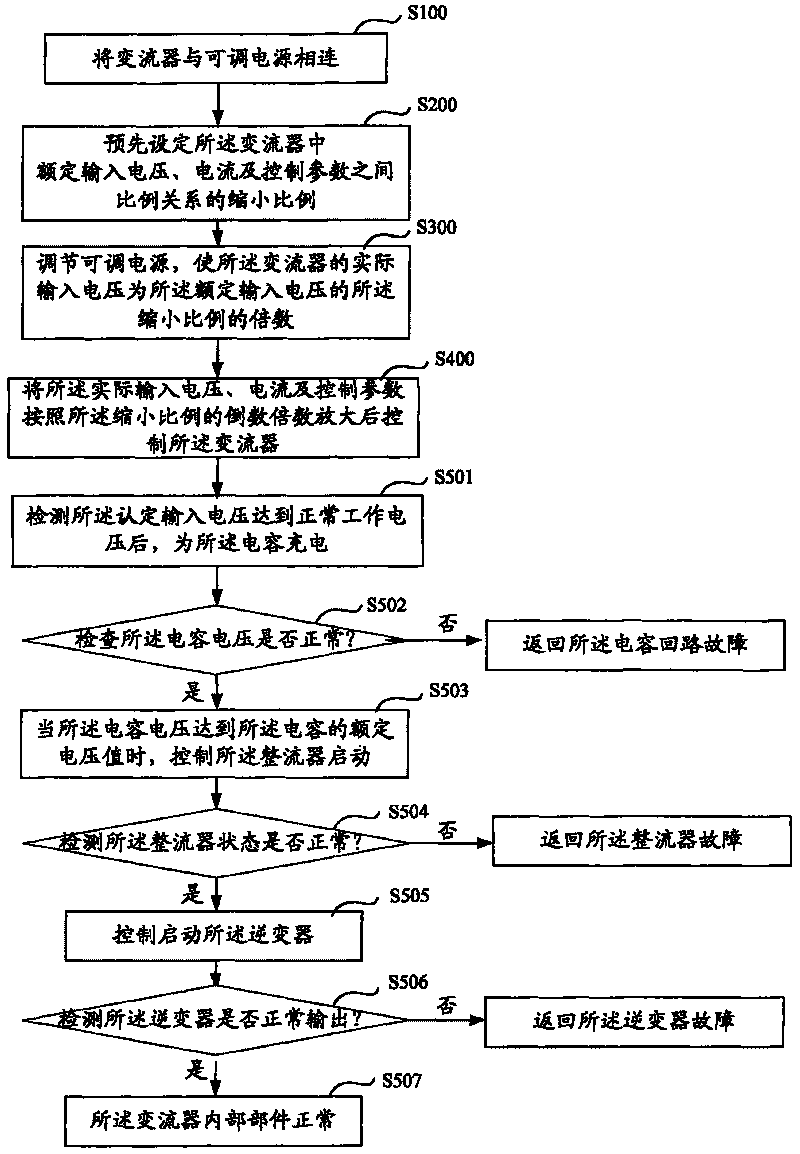

[0052] see figure 1 , which is a flow chart of the first embodiment of the current transformer testing method of the present invention.

[0053] The detection method of the converter described in the first embodiment of the present invention includes the following steps:

[0054] S100. Connect the converter to the adjustable power supply.

[0055] The measured converter is connected with an adjustable power supply, and the converter is powered by the adjustable power supply.

[0056] S200. Preset the reduction ratio of the proportional relationship among the rated input voltage,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com