Electrical control method used for single electric motor dragging multiple plungers

A technology of electrical control and control method, applied in the direction of electrical program control, digital control, etc., can solve the problems of large investment, poor reliability, and poor heat dissipation effect of the control drive system, and achieve the effect of good reliability, high precision, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

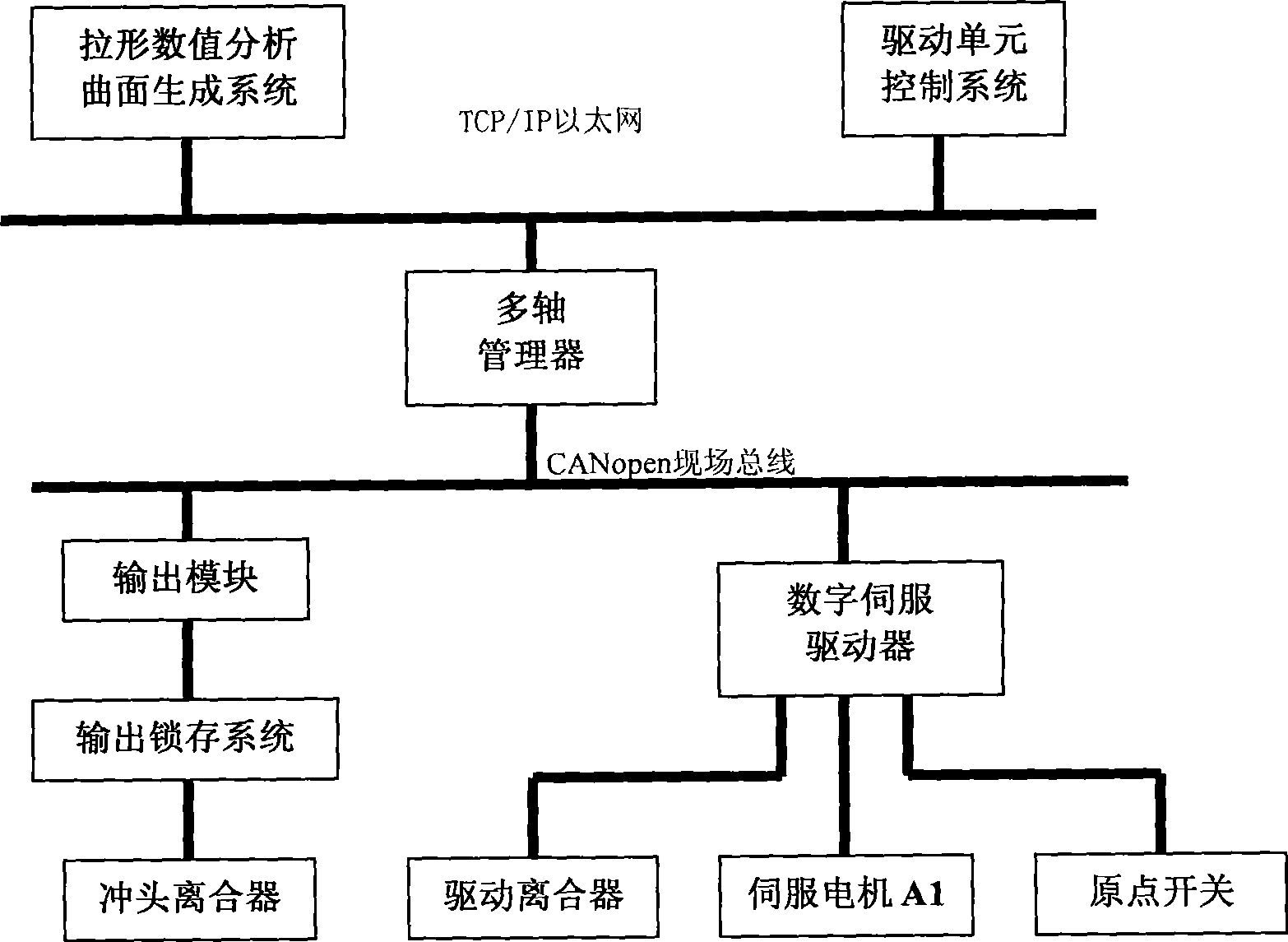

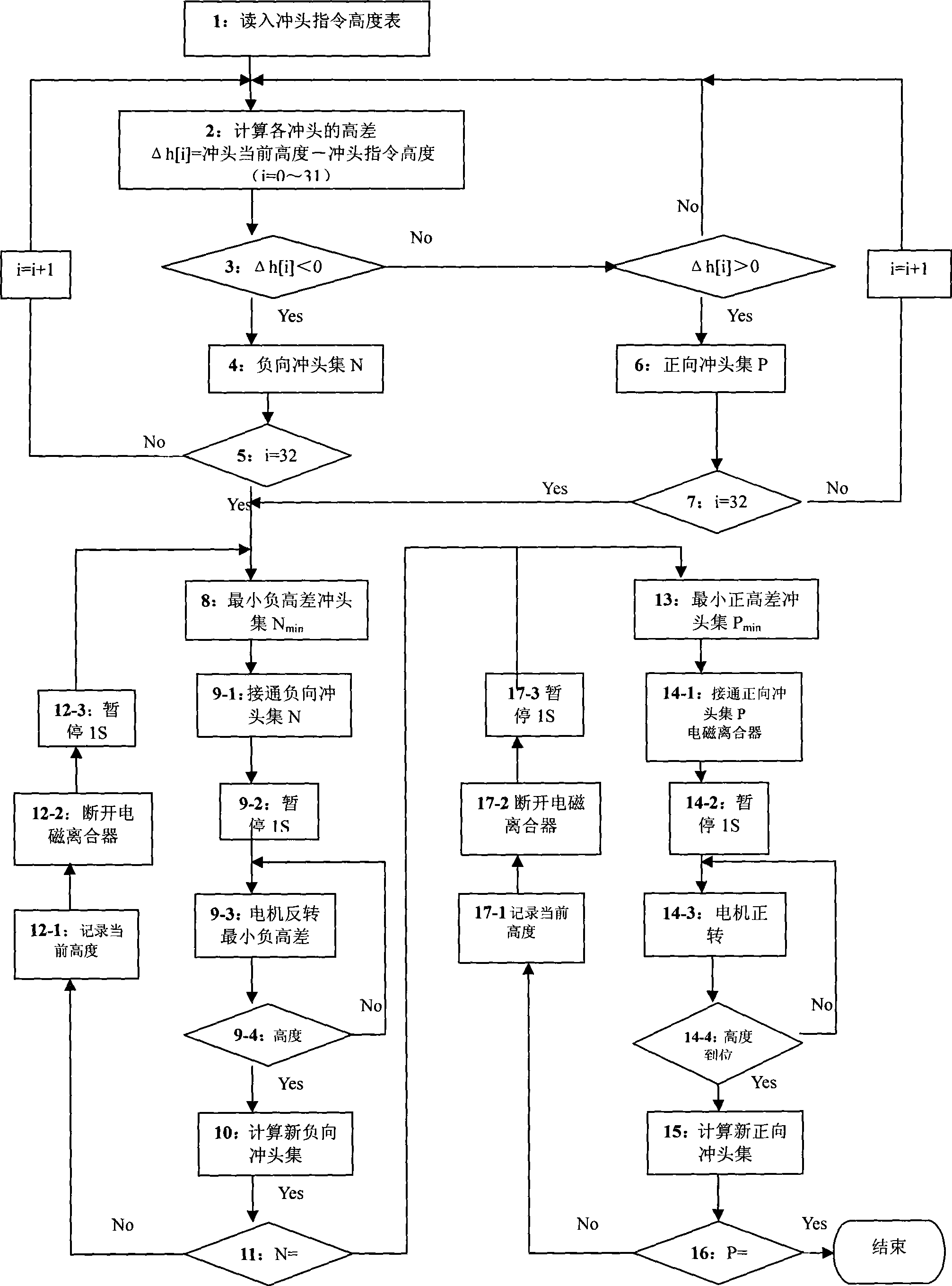

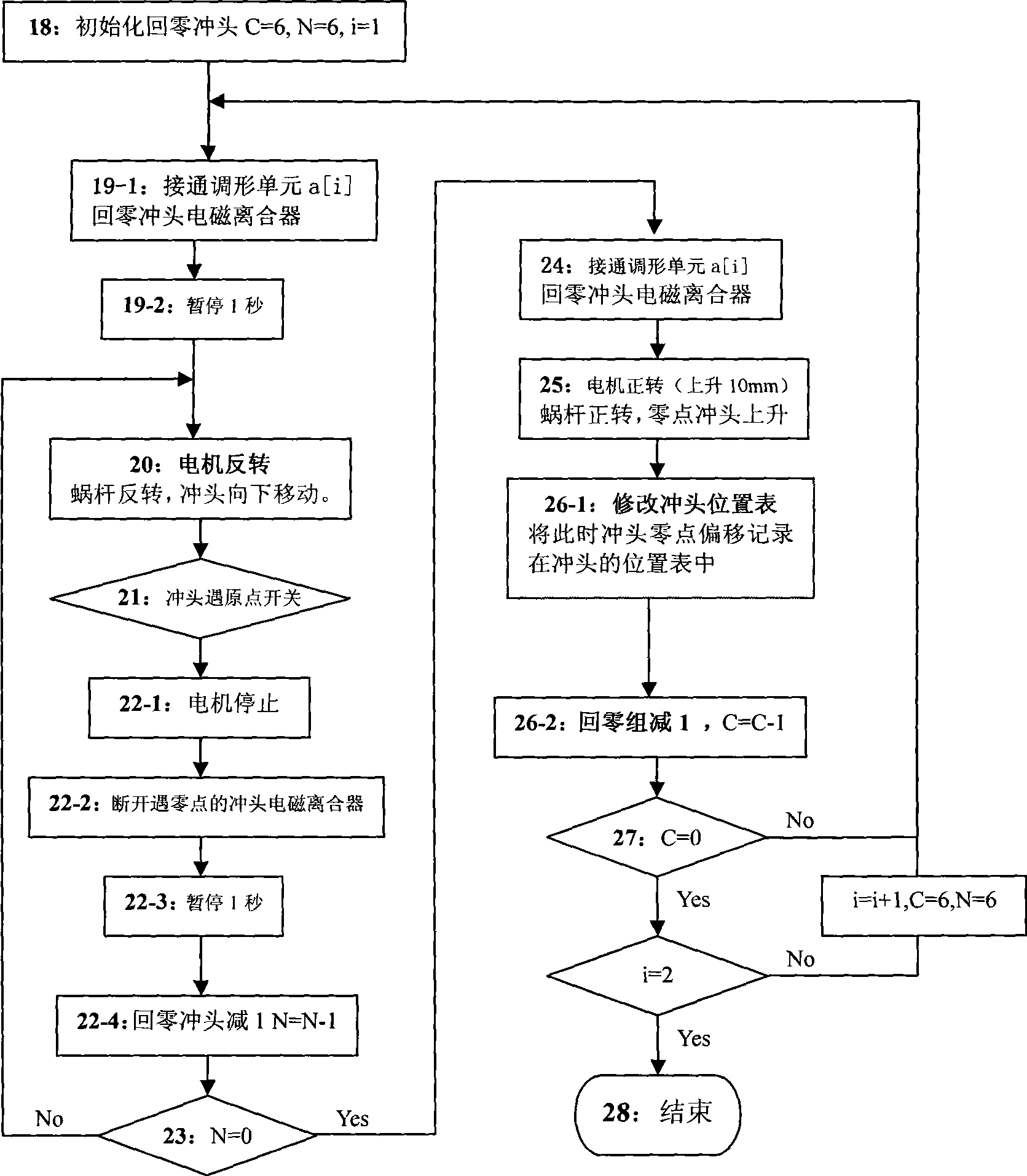

[0067]The electrical control system of the flexible multi-point mold drive unit is composed of a PC, a multi-axis control manager, an intelligent digital servo drive, an AC servo motor, and a CANOPEN output module, and various inputs are connected to the periphery. Output switches (Hall elements, relays, solenoid valves, clutches), etc. The control process is as follows: 1. Generate a punch height instruction worksheet according to the shape of the formed product, the punch size and the working range of the mold. 2. System connection, that is, the Ethernet connection between PC and multi-axis controller; 3. Die punch grouping for coordinate zero return operation; 4. Importing system worksheet files, including punch origin offset and punch backlash Compensation, punch adjustment status, punch current height, punch height instruction worksheet; 5. Adjust the punch height; 6. After the adjustment is completed, close the worksheet file.

[0068] The punch height adjustment proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com