Optimized furnace combination method and system for cold rolling hood type annealing furnace unit

A bell annealing furnace and optimization group technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of low utilization rate of bell furnace, low quality of annealed coils, and low production capacity of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

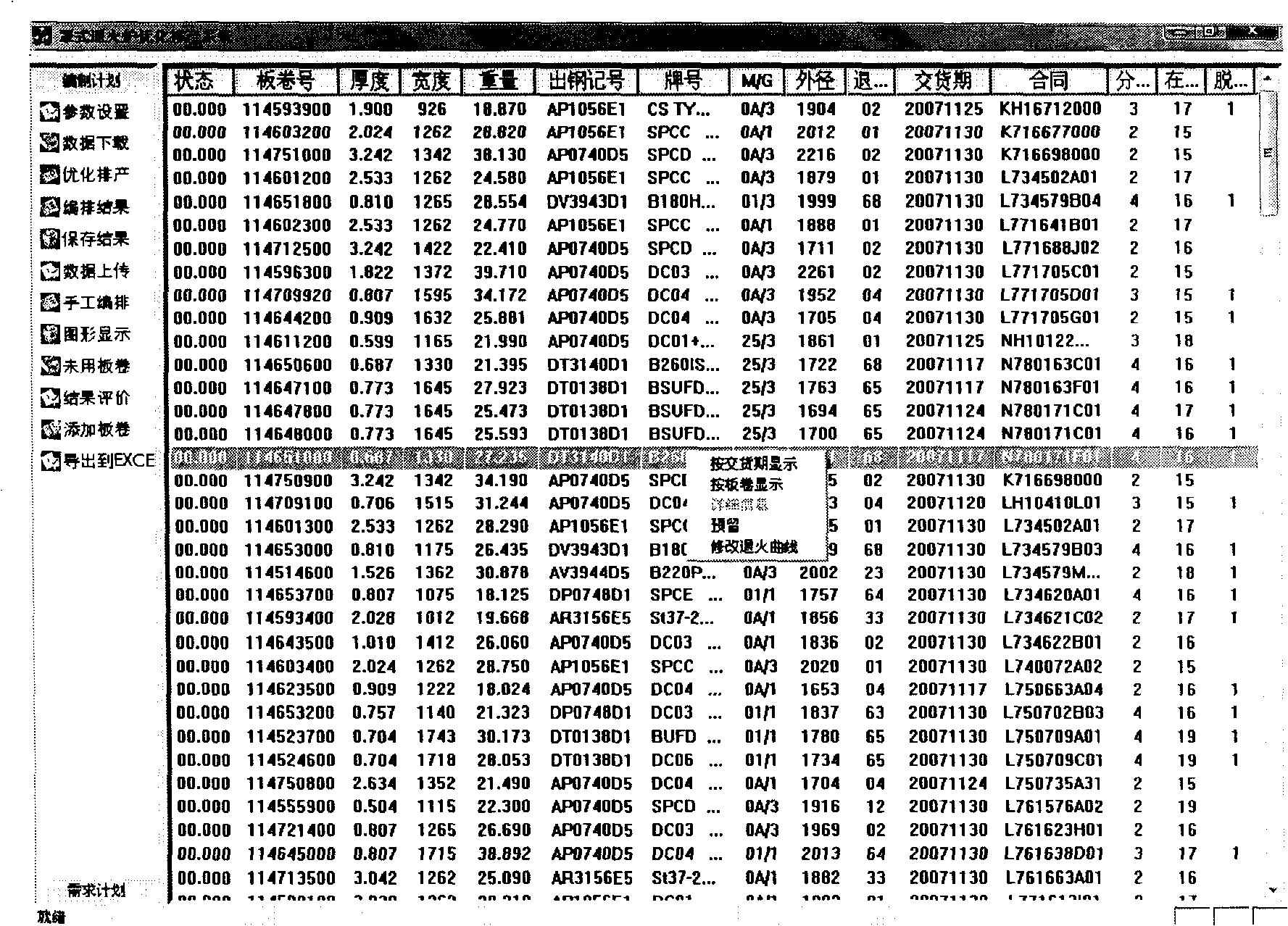

[0131] Example 1: In this embodiment, furnace loading combination is carried out for 20 coils and 3 bell annealing furnaces, in which the coil number is the index item for uniquely identifying coils, and the furnace loading combination is carried out according to the process requirements, and each furnace can hold up to 4 plates roll.

[0132] Volume number

thickness

Roll weight

width

Annealing curve

Contract No

outer diameter

delivery date

Sorting degree

1

1.264

28.11

1512

01

L750739B11

1835

20071231

2

2

2.522

32.21

1511

01

LH10432A07

1958

20071205

3

3

0.599

25.4

1551

11

N770465B02

1761

20071117

3

4

1.213

28.58

1262

02

L761656D02

2029

20071130

2

5

0.807

34.123

1525

64

L780834A01

...

example 2

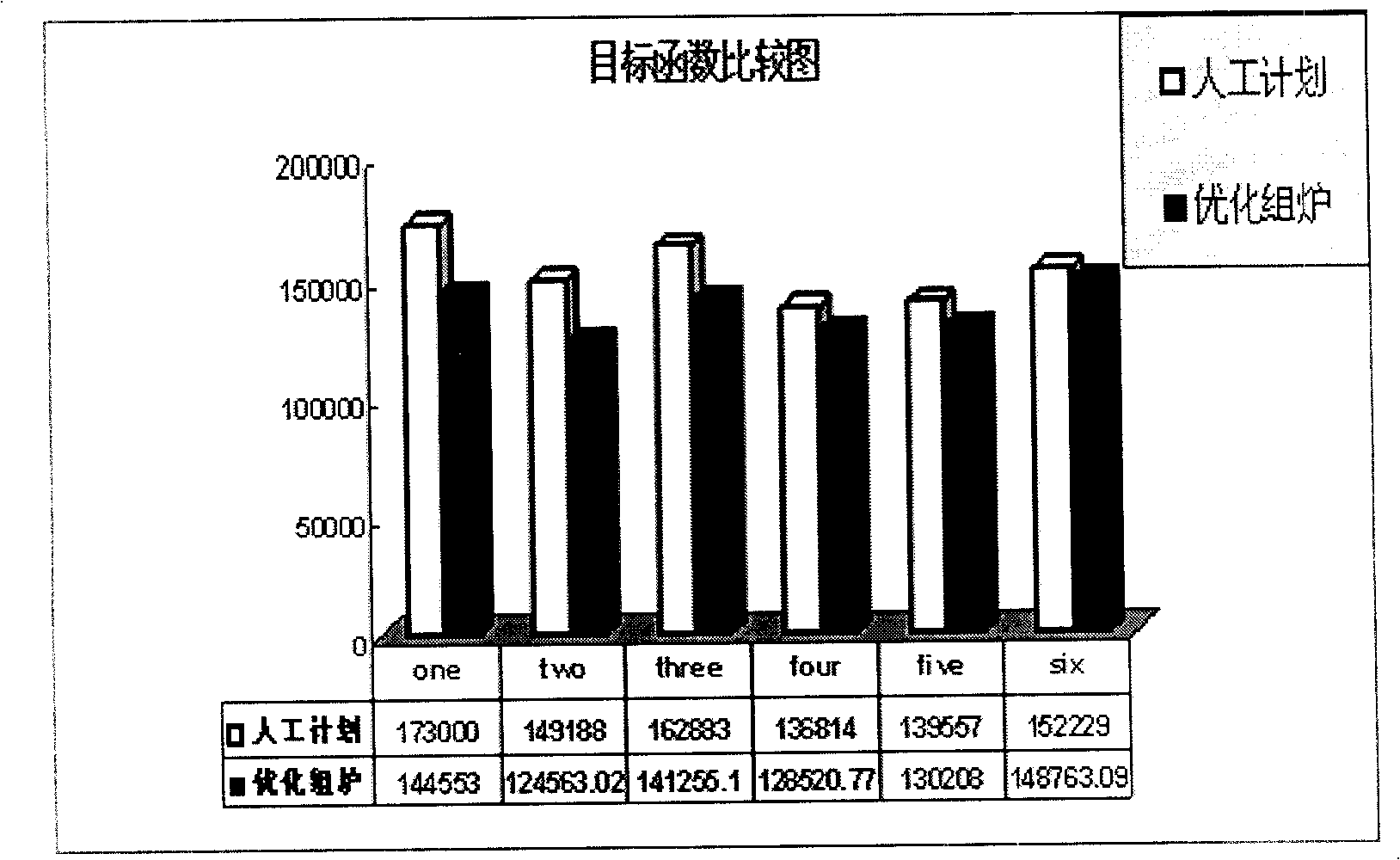

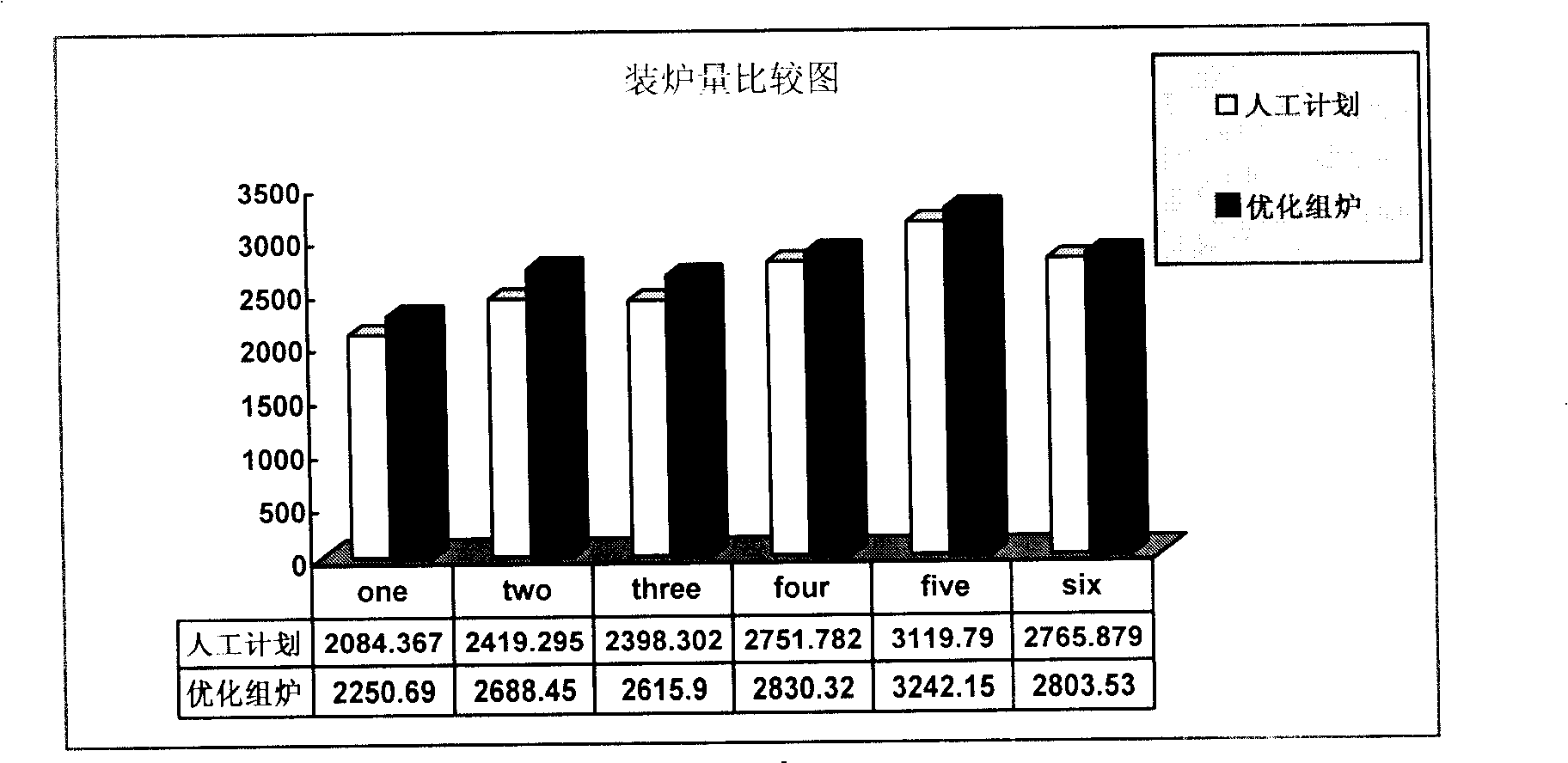

[0198] Example 2: Using the actual layout data of the bell furnace units in the steel plant as the specific implementation object, a total of 139 coils and 26 bell furnaces are combined in this embodiment.

[0199] The operation steps are the same as in Embodiment 1, and the parameter settings are shown in the table below:

[0200] serial number

Expenses

the symbol

specific parameter value

Remark

1

Number of coils

N

139

2

Furnace times

P

26

Two NH furnaces, one HH furnace

3

Furnace capacity

T j

155 99

Big Furnace 155 Small Furnace 99

4

remaining capacity charge

p j

0.5 / t+0.01 / mm

5

Unarranged coil cost

f i

60

6

Furnace Maximum Loading Height

H j

4700

[0201] Other parameter settings and solution process are the same as the first embodiment. Get the following results to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com