Exhaust gas after-treatment device

An exhaust gas post-treatment and exhaust gas technology, which is applied in exhaust treatment, exhaust devices, noise reduction devices, etc., to avoid direct thermal loading and simplify the effect of exhaust gas post-treatment devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

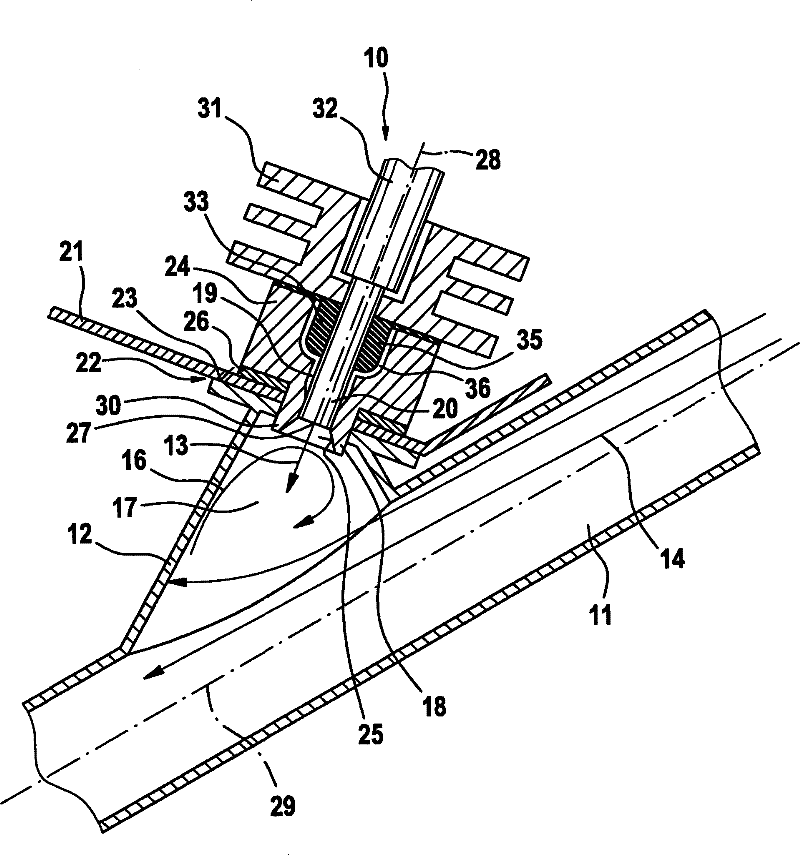

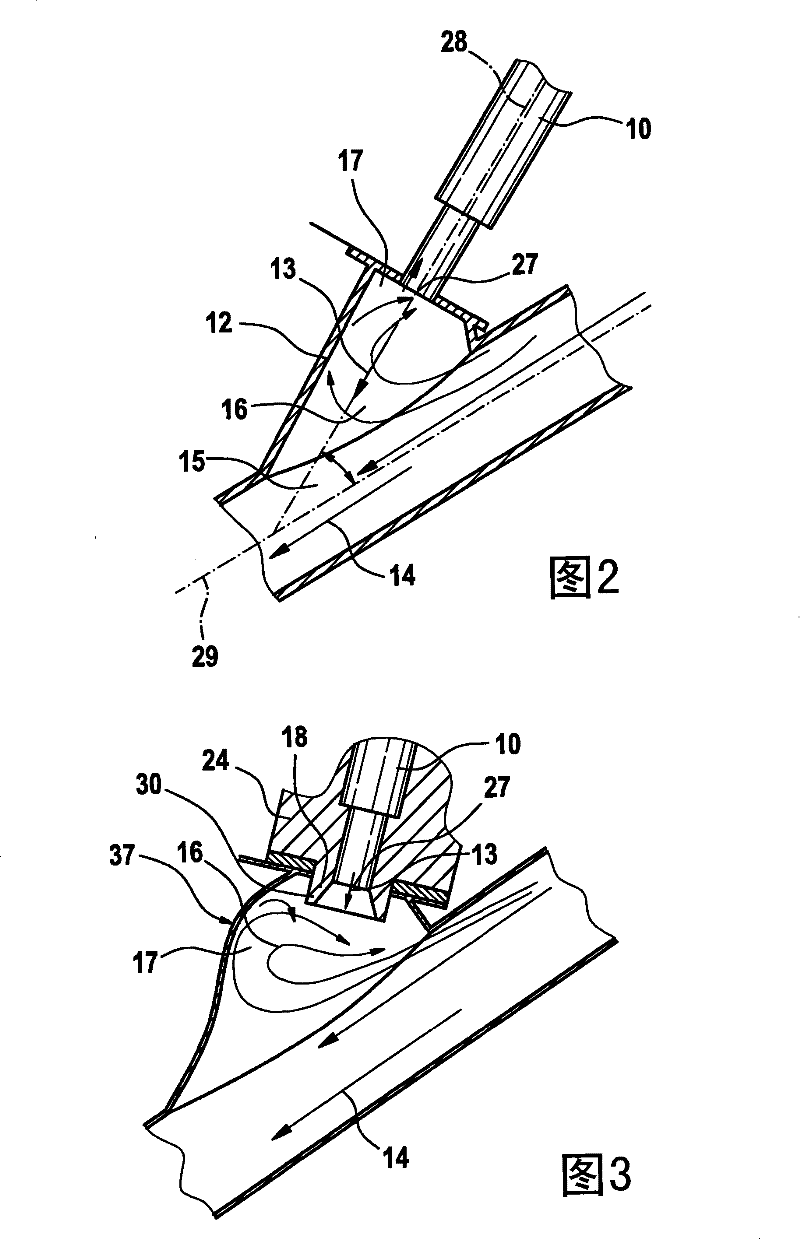

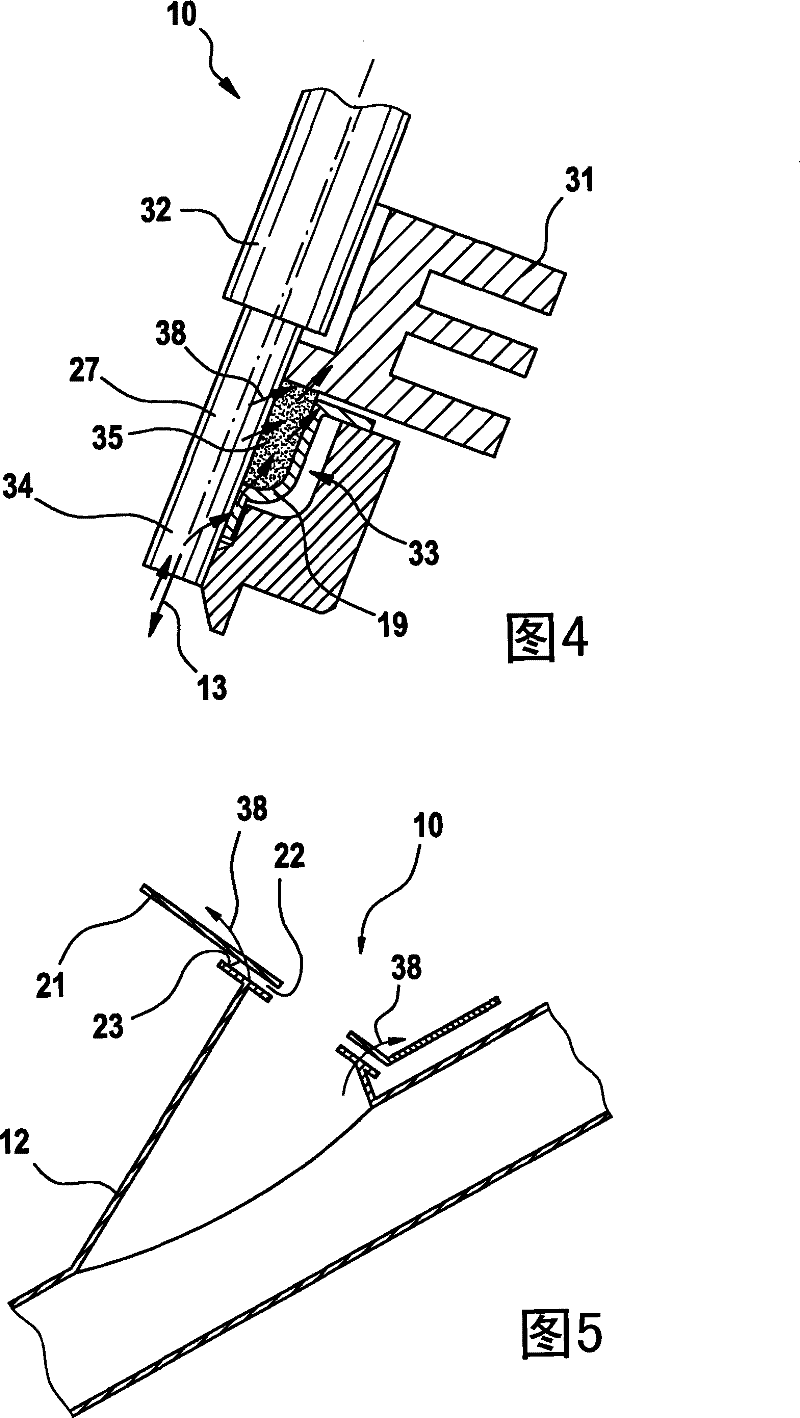

[0021] figure 1 A preferred embodiment of an exhaust gas aftertreatment device according to the invention for aftertreatment of exhaust gases in an exhaust system of an internal combustion engine is shown in a schematic sectional view, in which A catalytic converter (not shown) is provided for reducing the NOx fraction of the exhaust gas of the internal combustion engine. figure 2 , Figure 4 , Figure 5 and Figure 6 Each shows figure 1 detail view of the . image 3 An alternative embodiment of the flange 12 is shown. Like elements are numbered likewise in each of these figures.

[0022] The reducing agent is introduced into the exhaust pipe 11 along the inflow direction 13 via the valve tip 27 of the metering valve 10 . In the exhaust pipe 11 , the hot exhaust gas flow flows in the exhaust gas flow direction 14 . The exhaust line 11 is designed in such a way that less heat is introduced directly into the metering valve 10 and / or more heat can be discharged from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com