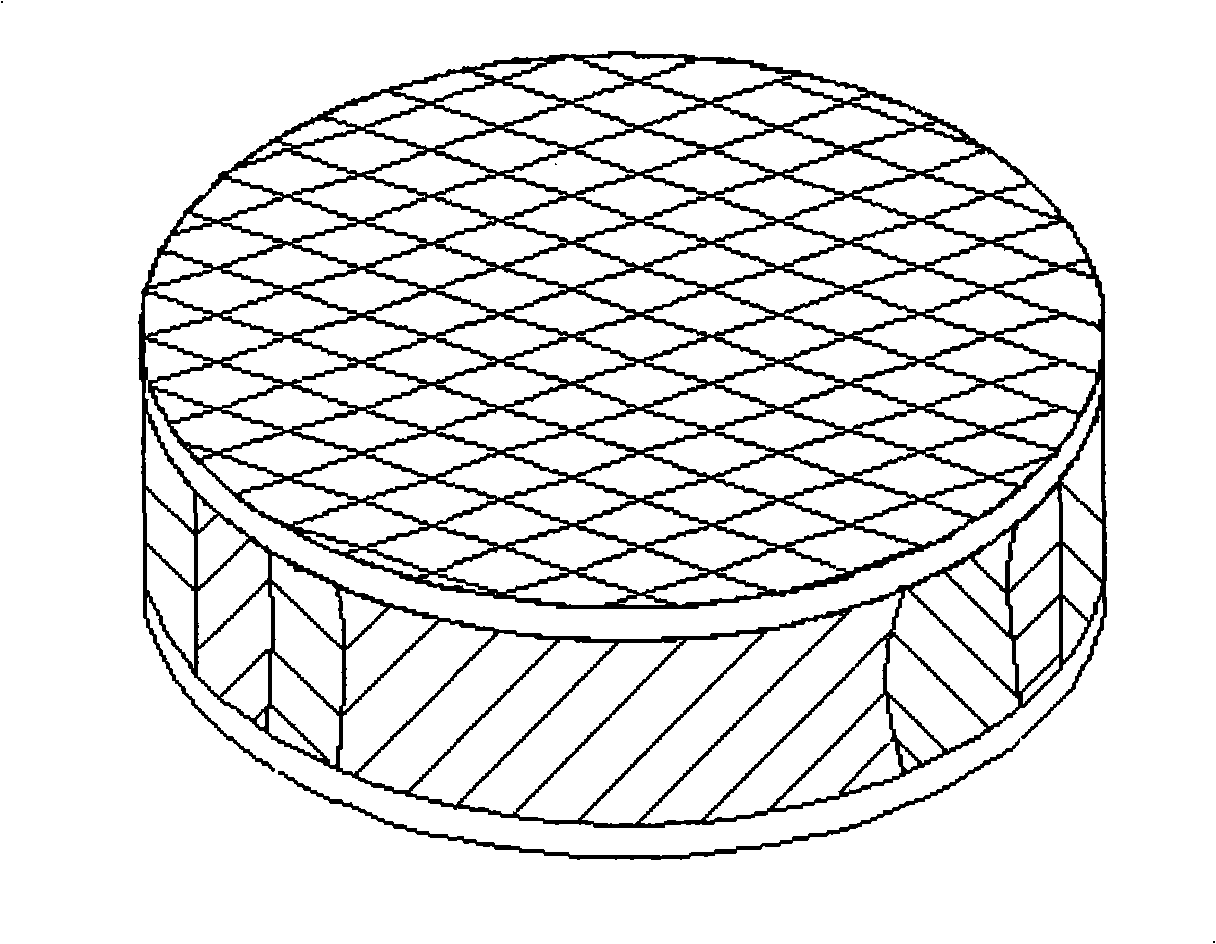

Strong-effect regular packing without wall flow

A structured packing, powerful technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the difficult effective mass transfer area and cannot fundamentally solve the wall flow effect and other problems, to achieve the effect of redistribution, solve the problem of wall flow in the tower, and wide operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

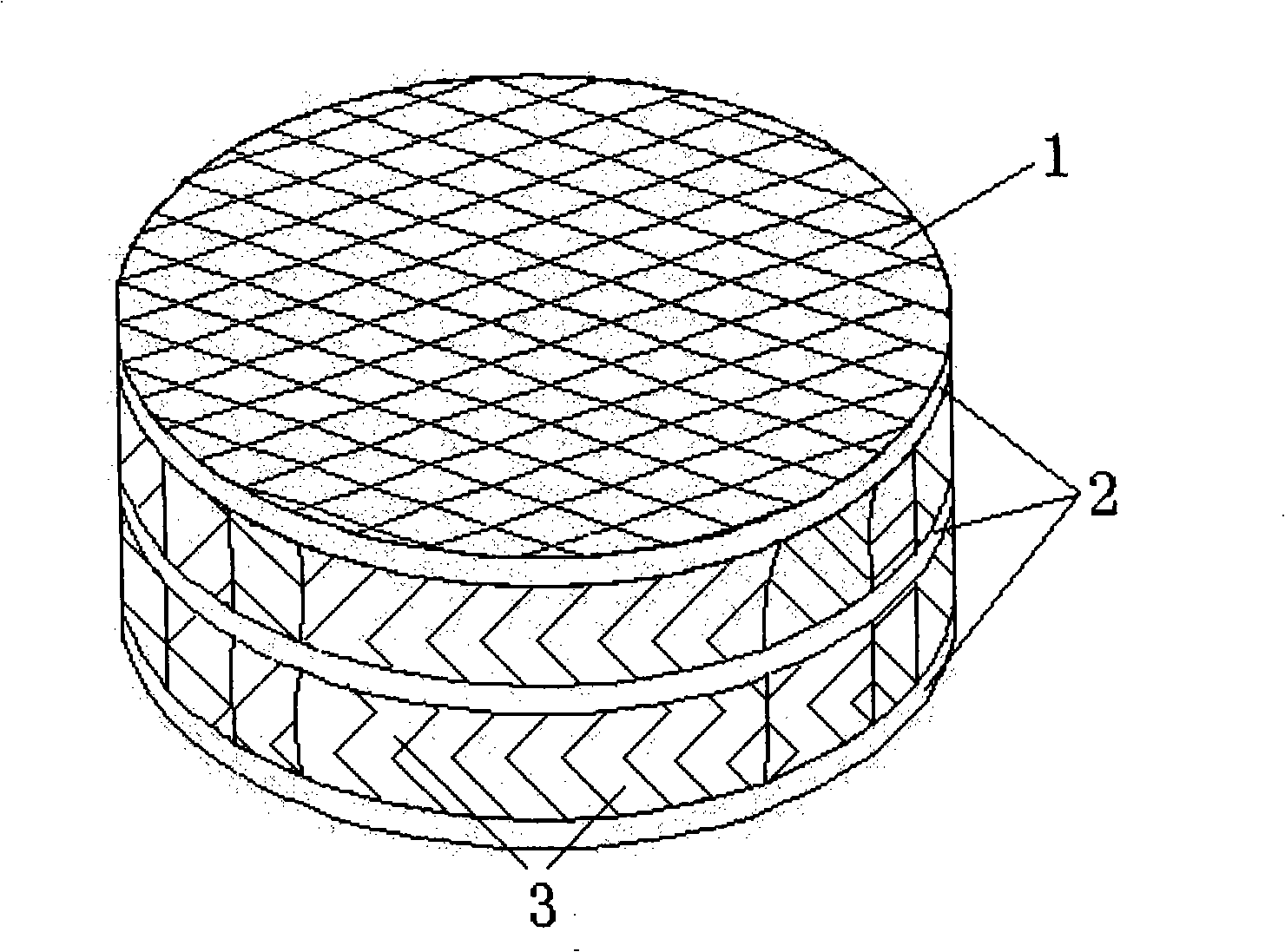

Embodiment 1

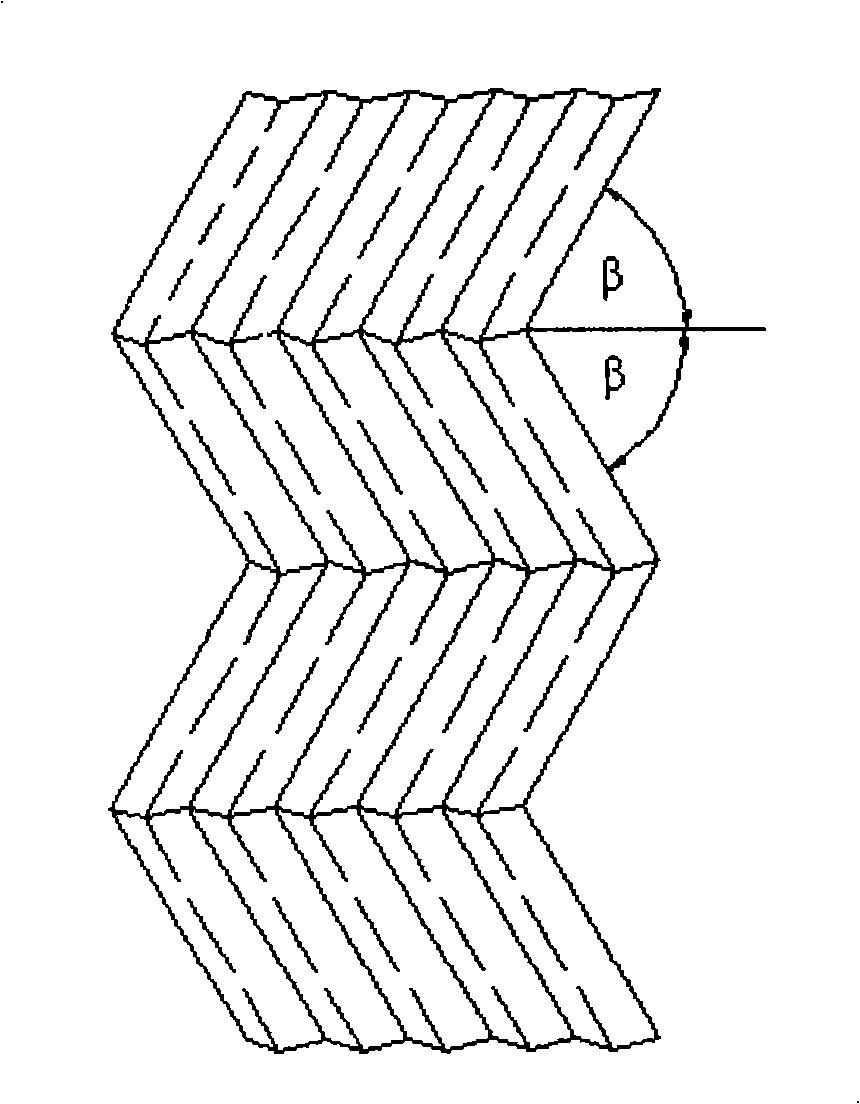

[0030] Methanol-water rectification separation, the diameter of the tower is 1000mm, and the packing of 10m is used. The packing used is the powerful non-wall flow corrugated structured packing of the present invention. The number N of corrugated channels on each corrugated plate is 4, α and β are both 45°, and the corrugated channels are distributed with equal lengths. After the surface of the corrugated sheet is treated accordingly, it is fixed and assembled into a structured packing disk with bands. The structured packing has a specific surface area of 600m 2 / m 3 , the separation index provided is about 5-6 theoretical plates / m, and the separation index for methanol is: feed methanol composition is 38% (weight percent), and the rest is water. The composition of methanol obtained by separation at the top of the tower is 99.9%, and the content of methanol in the bottom component is about 0.001%. Observation with an industrial endoscope reveals that with the structured p...

Embodiment 2

[0032] The basic parameters are the same as in Example 1, but the angle α between the corrugated sheet and the axial center line of the packing is adjusted to 35°, and the specific surface area of the structured packing can reach 650-700 m 2 / m 3 , due to the adjustment of the α angle, the arrangement of the corrugated channels is more compact, the total number of corrugated channels with the same packing height is higher than that of Example 1, the residence and mixing degree of the materials on it are improved, and the separation efficiency of the packing is improved compared with the traditional packing Nearly 17%, which is 1-3% higher than that of the packing of the present invention used in Example 1, and the separation index provided by the structured packing can even reach 7 theoretical plates / m.

Embodiment 3

[0034] Each basic parameter is the same as embodiment 1, but adopts the straight line of 8mm long as transition (such as Figure 5 ), with the help of industrial endoscope observation, it is found that the liquid can flow vertically downward along the zigzag channel, which greatly eliminates the occurrence of wall flow and other phenomena, and the existence of the transition section prolongs the stay of the liquid in the channel Time, and is conducive to the redistribution of liquid. By comparing the measured data, it is found that relative to the traditional structured packing, the residence time of the liquid in the packing increases by nearly 20%, although the height of the whole tray is increased relative to the novel tray in Example 1 due to the increase of the transition section, but due to The prolongation of the residence time and the redistribution effect of the transition section make the separation efficiency of the whole column not significantly changed compared wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com