Special screw for blow-moulding machine capable of using powder resin

A blow molding machine and screw technology, applied in the field of plastic blow molding machine equipment parts, can solve the problems of low cost, high production cost, high raw material, energy, labor consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

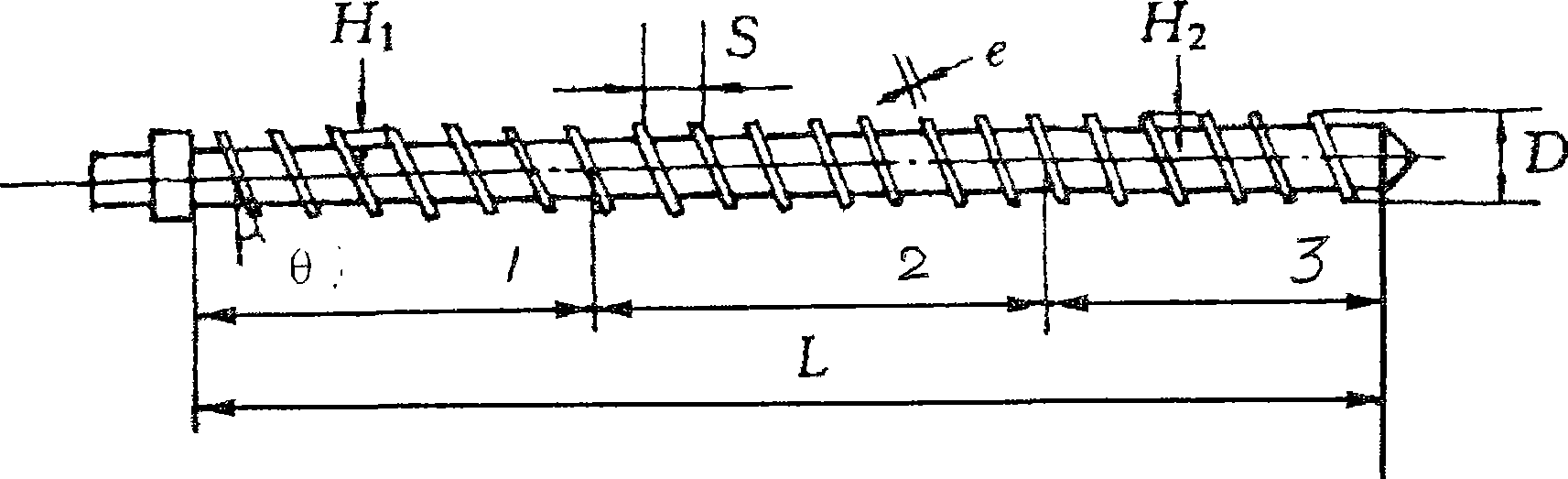

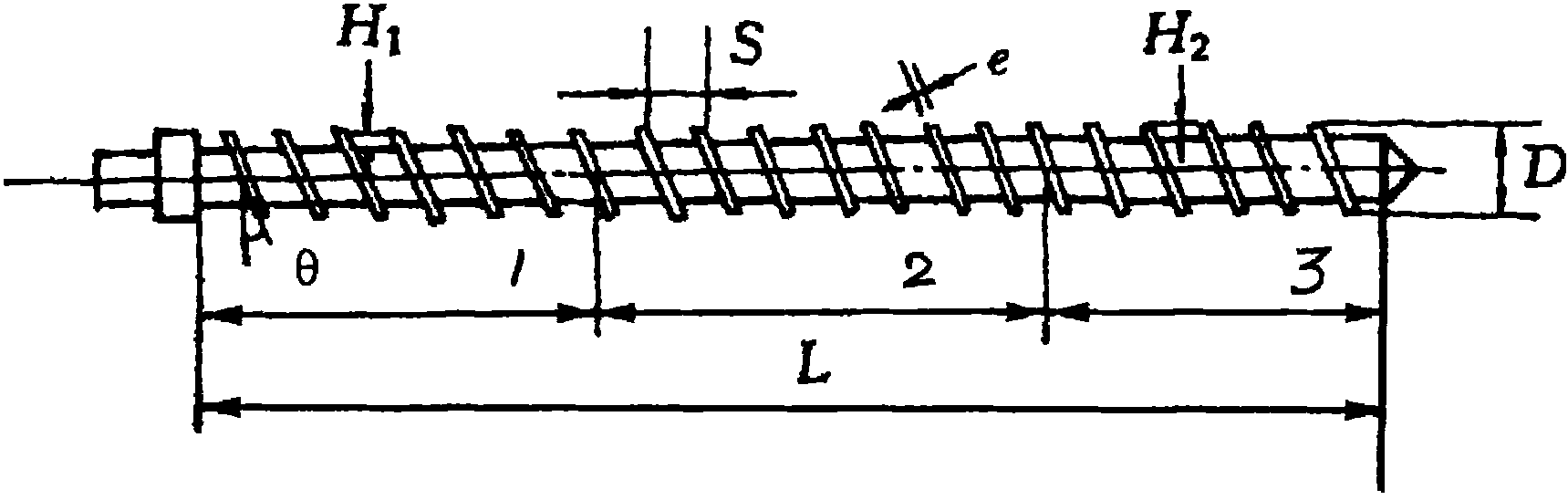

[0012] The special screw for blow molding machine that can use powder resin is a special screw for PVC blown film single-screw extruder that can use powder resin mixture as raw material.

[0013] The working principle of the special screw: the densely-pressed solid bed is in contact with the surface of the heated barrel during the advancement, and the melting starts from the contact part and leaves a layer of melt film on the surface of the barrel. Due to the relative motion of the barrel surface to the screw and the solid bed, a velocity distribution is created within the melt film formed between the barrel and the solid bed. When the thickness of the melt film exceeds the gap between the screw flight and the barrel, the melt will be "scraped" by the screw flight and sent to the propulsion surface of the screw flight to form a melt pool. Still a solid bed. In this way, as the solid bed moves forward along the screw groove, its width gradually decreases, and the width of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com