Sedimentation parabolic type multi-point discharge belt conveyor

A conveyor and material belt technology, applied in the field of settling parabolic multi-point unloading belt conveyor, can solve the problems of wear of flapper valve and other components, flapper valve mixing accident, material damage and other problems, to avoid mixing materials , to avoid wear and tear, the effect of complete unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

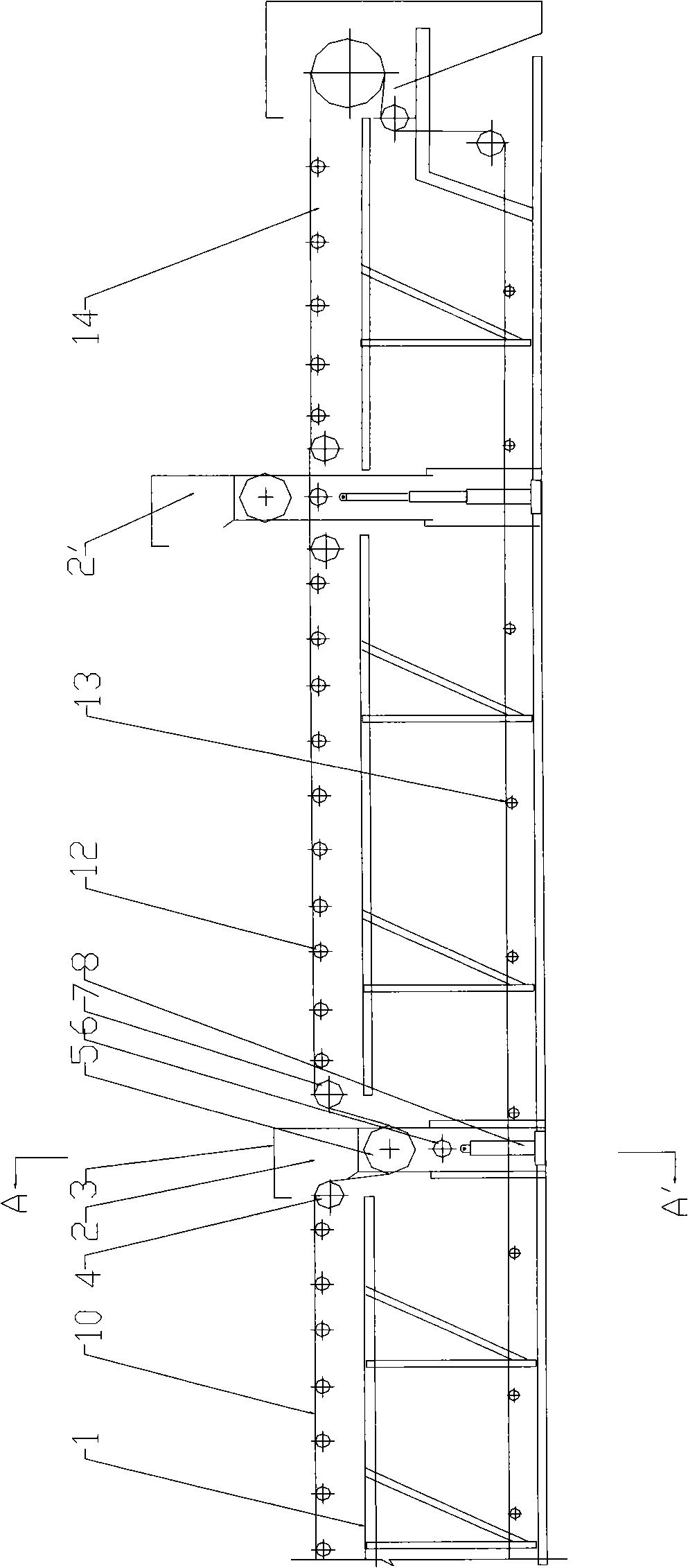

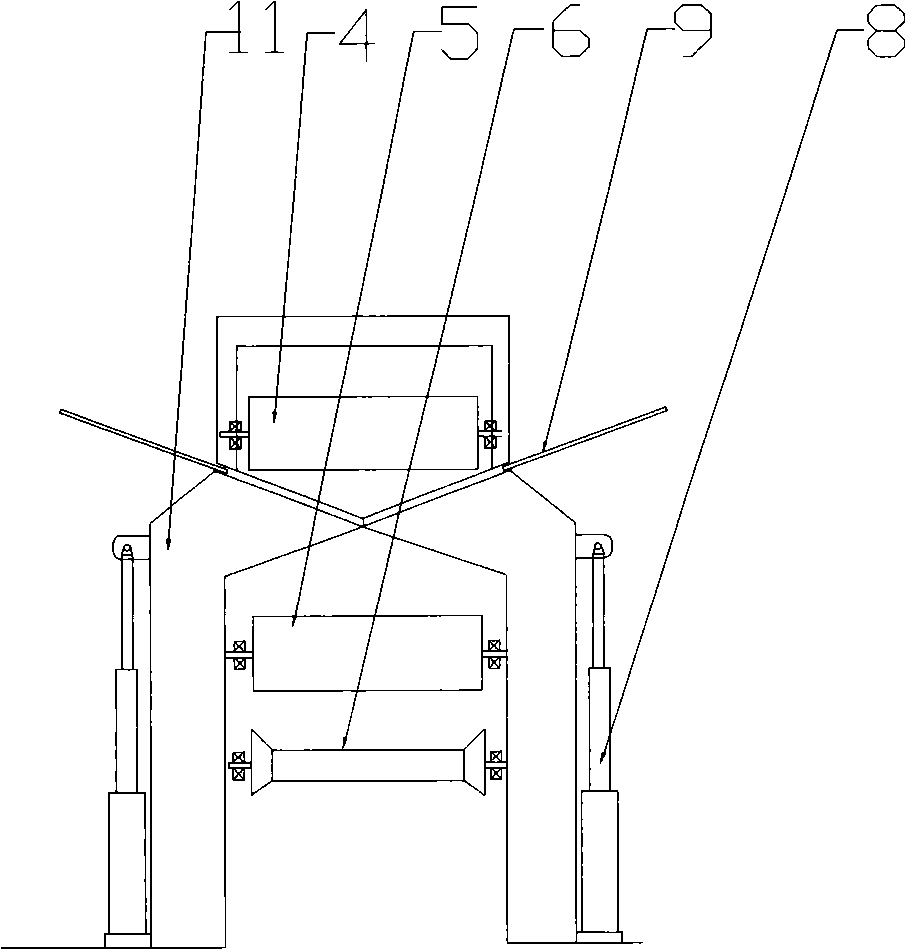

[0022] Such as figure 1 As shown, the transportation section 1 and the settlement discharge section 2 adopt relatively independent installations, so that the settlement parabolic guide trough 3 of the settlement discharge section 2 rises and falls freely without being affected by the transportation section 1; the head of the transportation section 1 is equipped with a parabolic redirection roller 4 , The parabolic reversing drum 4 faces forward to the parabolic guide trough 3 in the upper part of the parabolic section 2 of the subsidence.

[0023] The settling parabolic section 2 is composed of a settling parabolic guide trough 3. Both sides of the settling parabolic guide trough 3 are equipped with blanking chutes 11, and the upper ends of the two blanking chutes 11 are equipped with two-way gate valves 9; the settlement parabolic guiding chute 3 Settlement reversing roller 5 is installed in the middle part, lower idler roller 6 of settlement belt is installed in the lower part;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com