Firearms gun

A technology of artillery and weapons, applied in the direction of weapon type, launching device, projectile, etc., can solve the problems of complex structure of the gun barrel, affecting the life of the artillery, shooting stability and range, and high material cost, so as to increase and improve the stability and range. Combustion effect, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Selected embodiments of the present invention will now be described with reference to the accompanying drawings. It will be apparent to those skilled in the art from the disclosure that the following descriptions of the embodiments of the present invention are intended to illustrate the invention, rather than to limit the scope of the invention defined by the appended claims. The invention as claimed and limited by other equivalents.

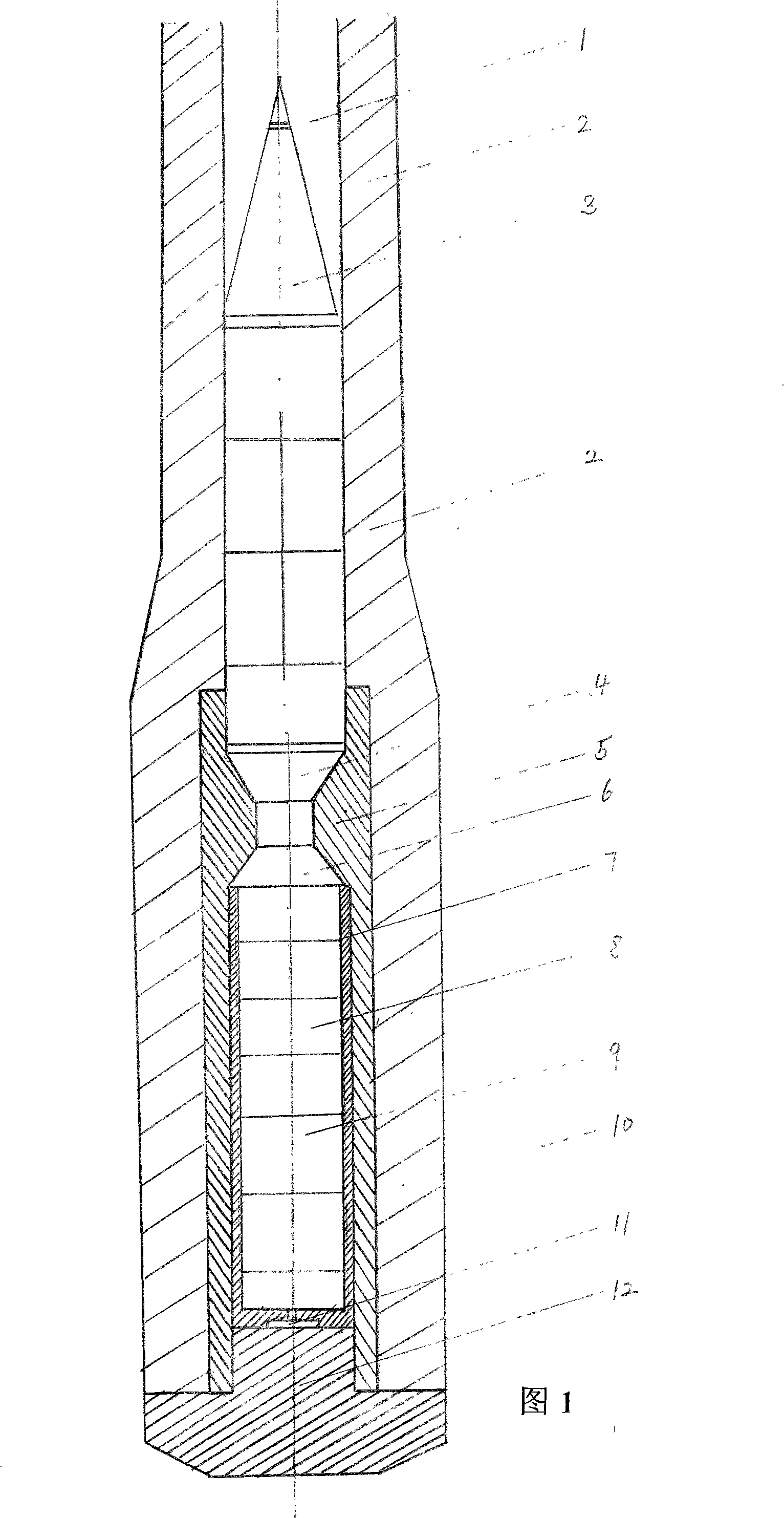

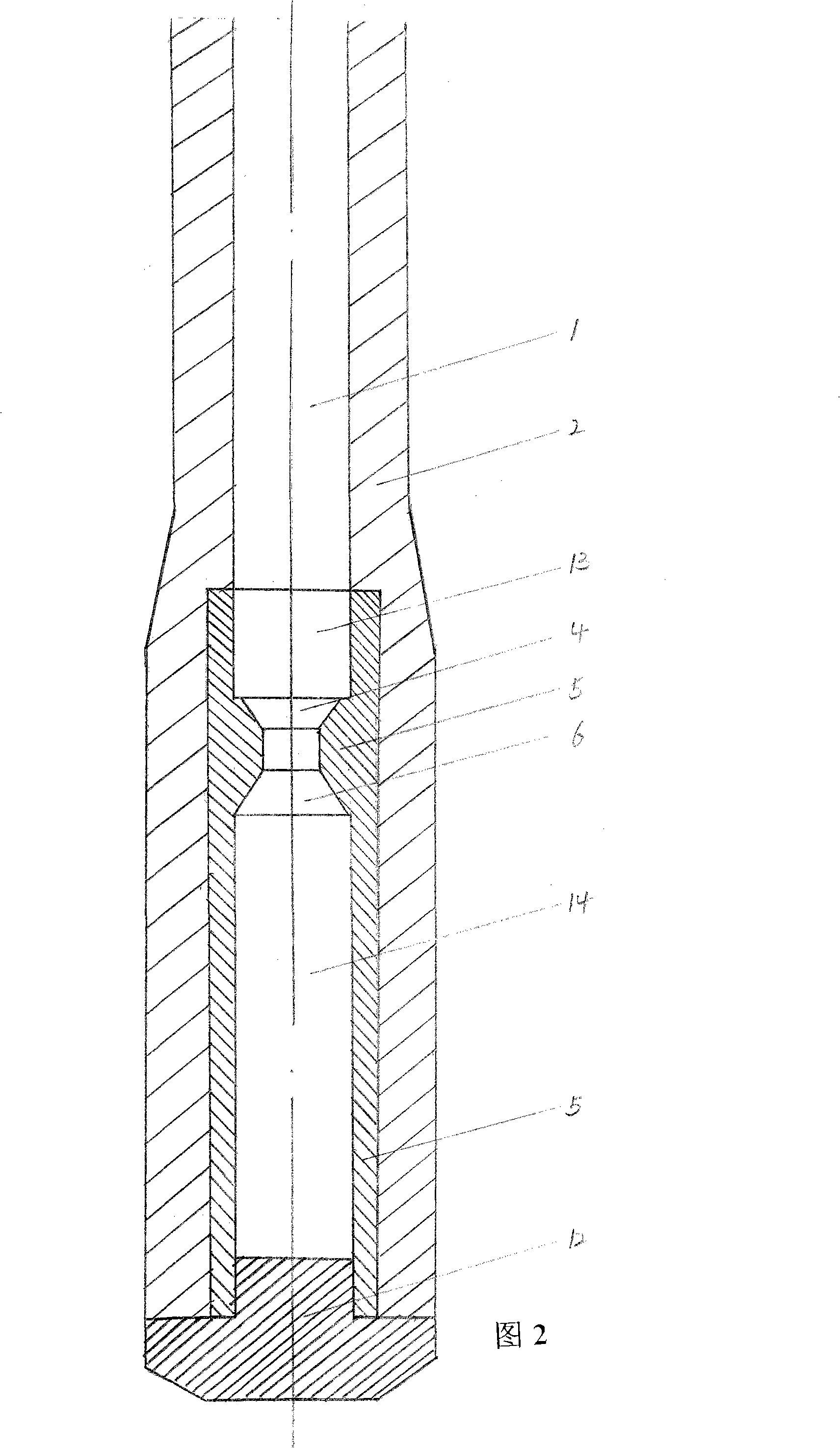

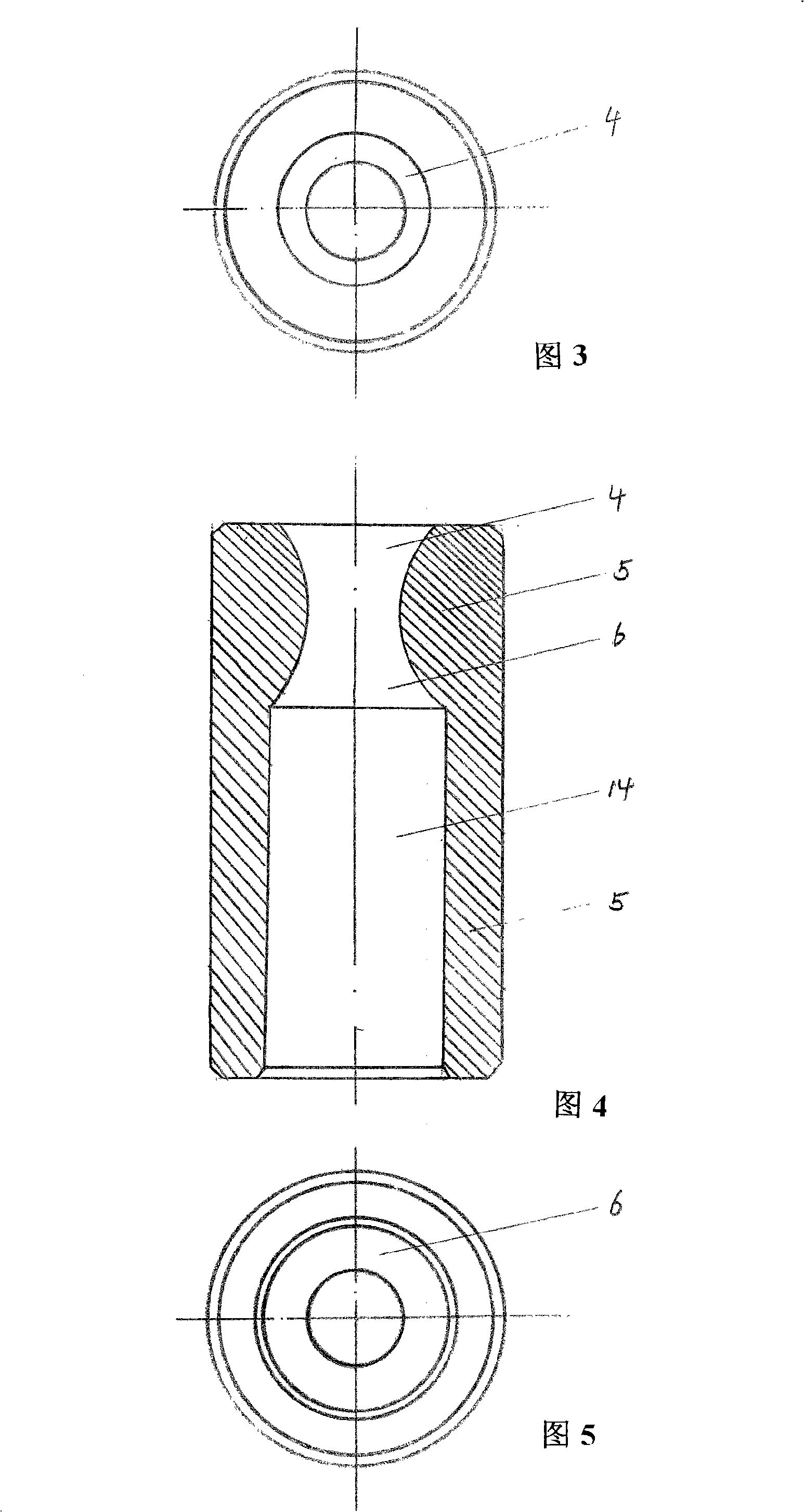

[0026] Among Fig. 1 to Fig. 2, the main structure of gas accelerator artillery weapon is by artillery bore (1), artillery barrel (2), expansion area (4), gas accelerator (5), contraction area (6), artillery body ( 10), fixer (12) forms. The warhead (3) is arranged in the gun bore (1) at the front of the gas accelerator (5), connected to the warhead guide area (13) of the gas accelerator (5), the propelling charge (8) in the ammunition casing (7) and The basic propelling charge (9) and the primer exciter (11) are arranged in the propellin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com