Miniature power-supply plug

A power plug, miniature technology, applied in the direction of contact parts, etc., can solve the problems of inconvenience, danger, high bending height, and achieve the effect of convenient plugging, not easy to damage, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

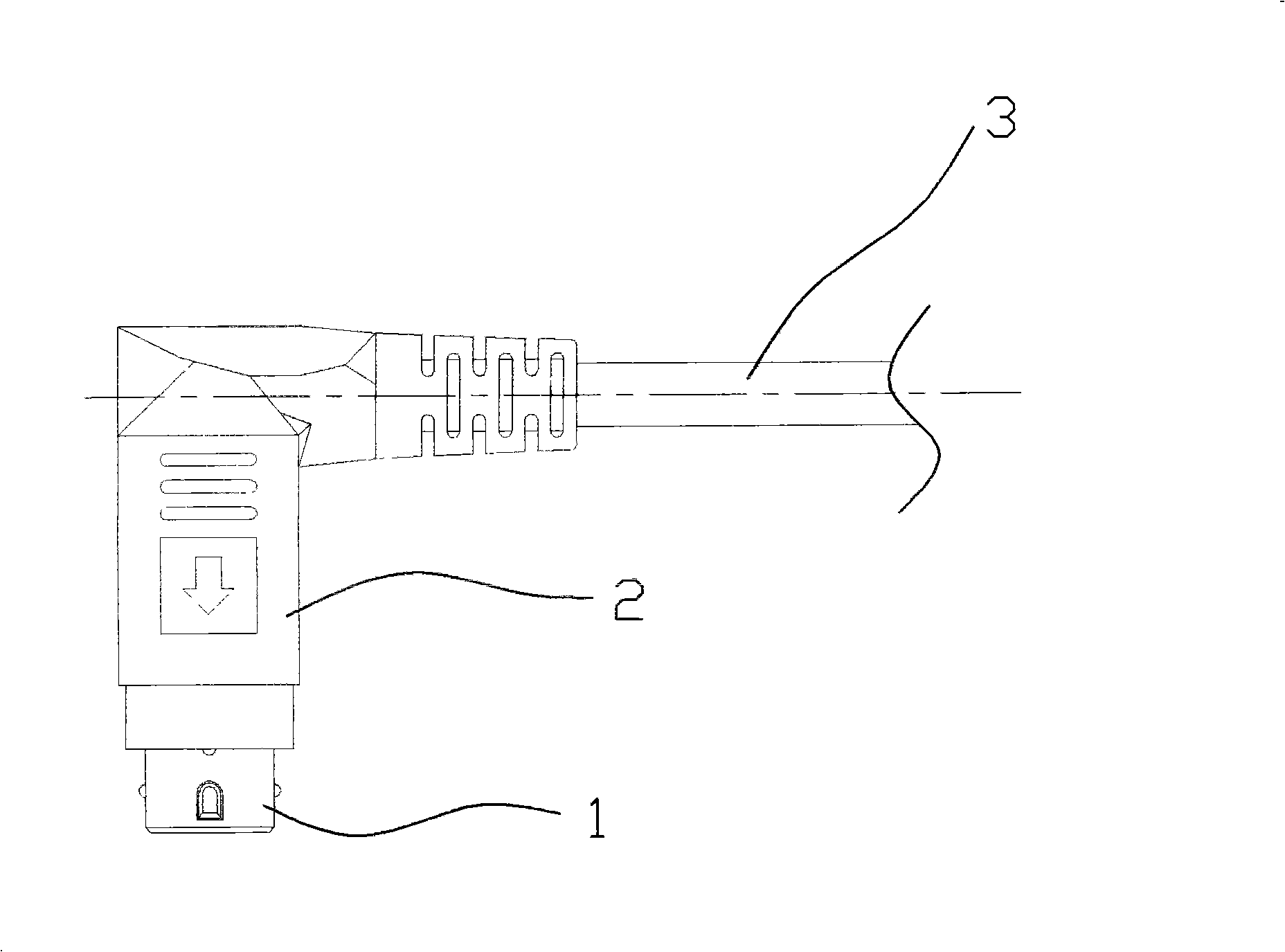

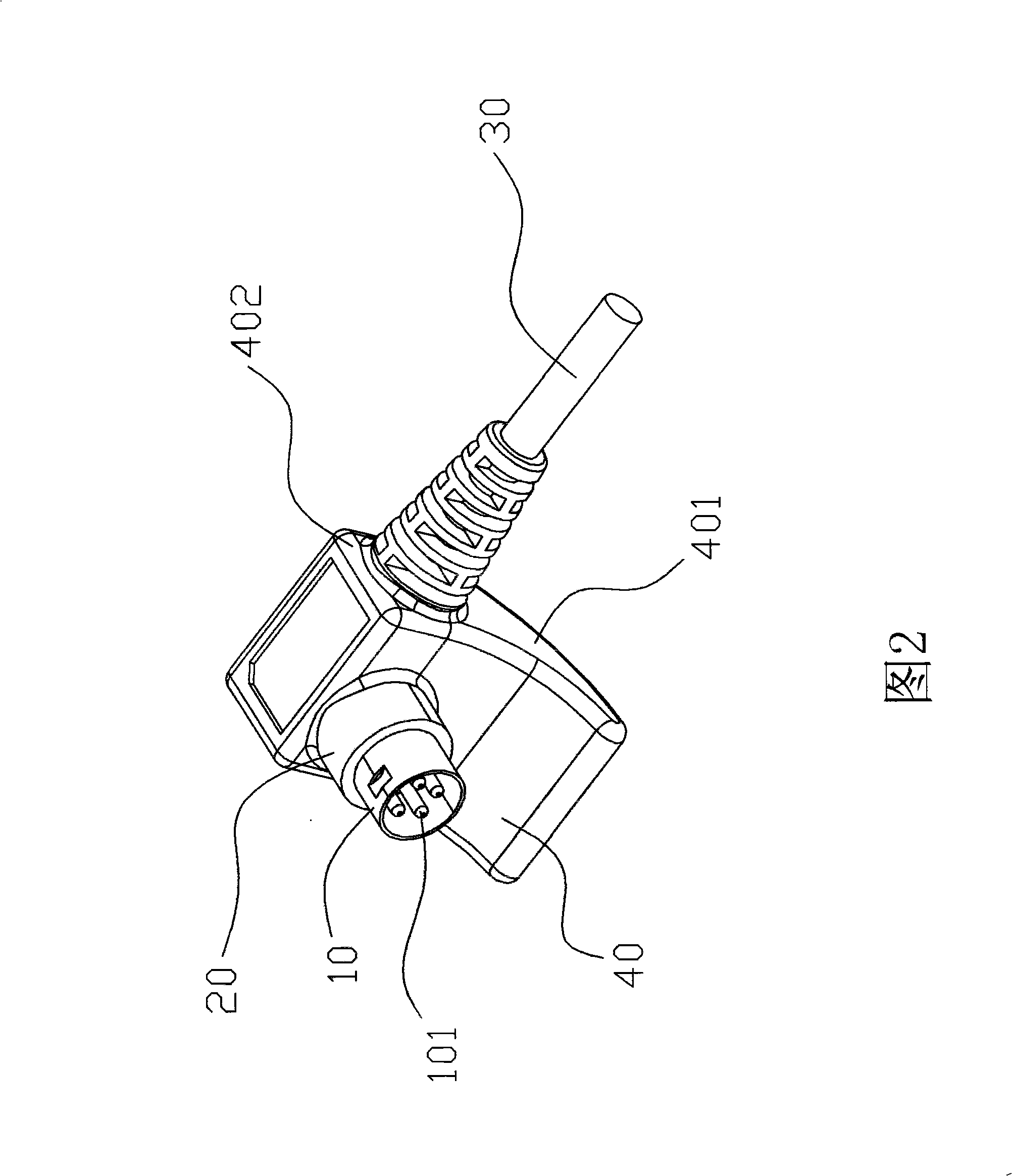

[0016] Please refer to FIG. 2 , which is a schematic structural view of a micro power plug according to a preferred embodiment of the present invention.

[0017] Therefore, in order to achieve the above object, a preferred embodiment of the miniature power plug of the present invention includes:

[0018] A conductive part 10 is inserted into a socket (not shown) to conduct electricity. In this embodiment, four conductive columns 101 are arranged inside. The four conductive columns are non-central and symmetrically arranged. The purpose of this design can achieve foolproof The effect, so as to avoid the wrong insertion;

[0019] A curved insertion part 20, electrically connected to the above-mentioned conductive part 10, its inside is a metal electrically connected to the above-mentioned conductive part 10, and its outside is covered with an insulator;

[0020] A wire 30 is electrically connected to the plug part 20, and in this embodiment, the wire 30 and the plug part 20 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com