Bevel edge processing method for multi plate printed circuit board after printing and fluting, and its milling cutter

A printed circuit board and processing method technology, which is applied in milling machine equipment, details of milling machine equipment, metal processing equipment, etc., can solve the problems of damaged surface edges of gold fingers, difficult insertion and removal, poor contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to fully disclose the present invention, a detailed description is now made in conjunction with the accompanying drawings.

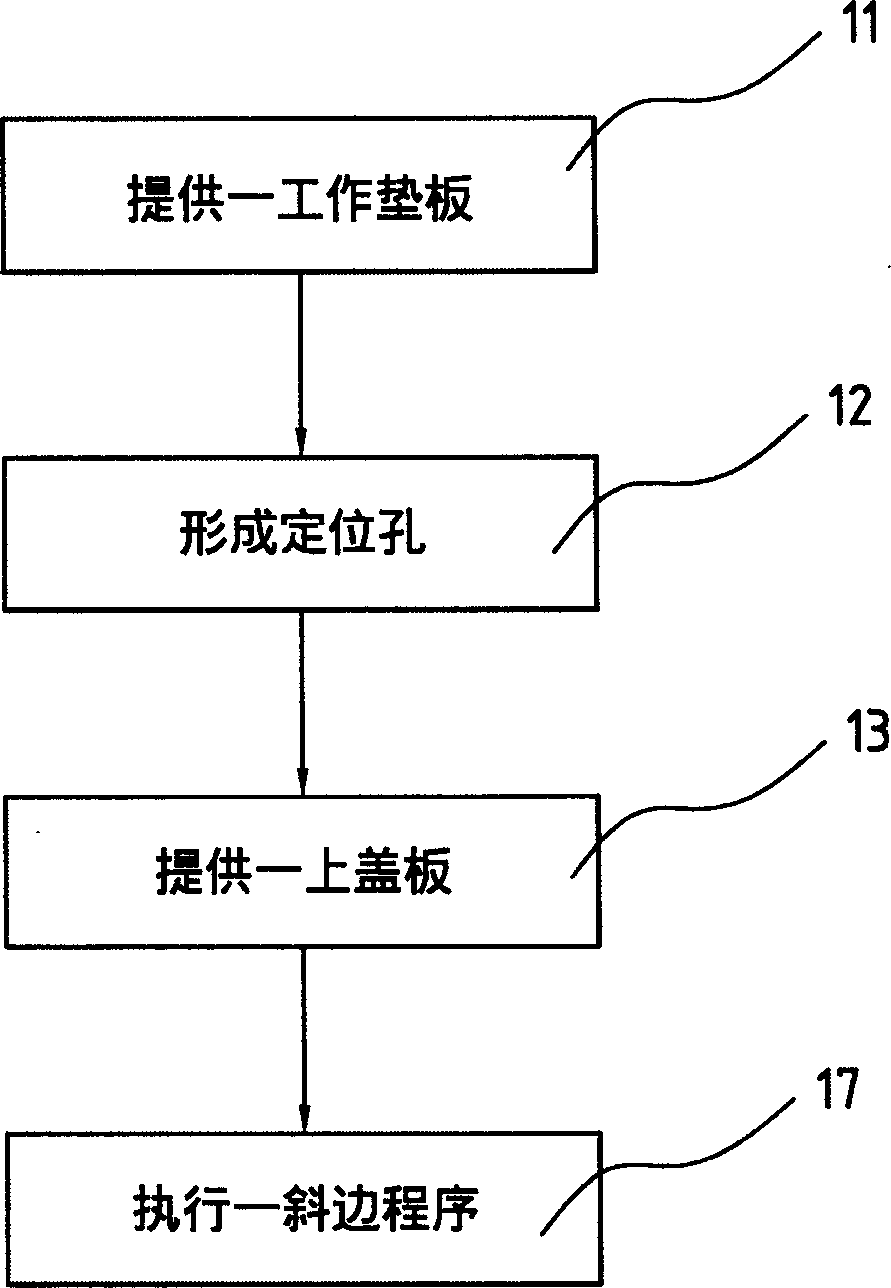

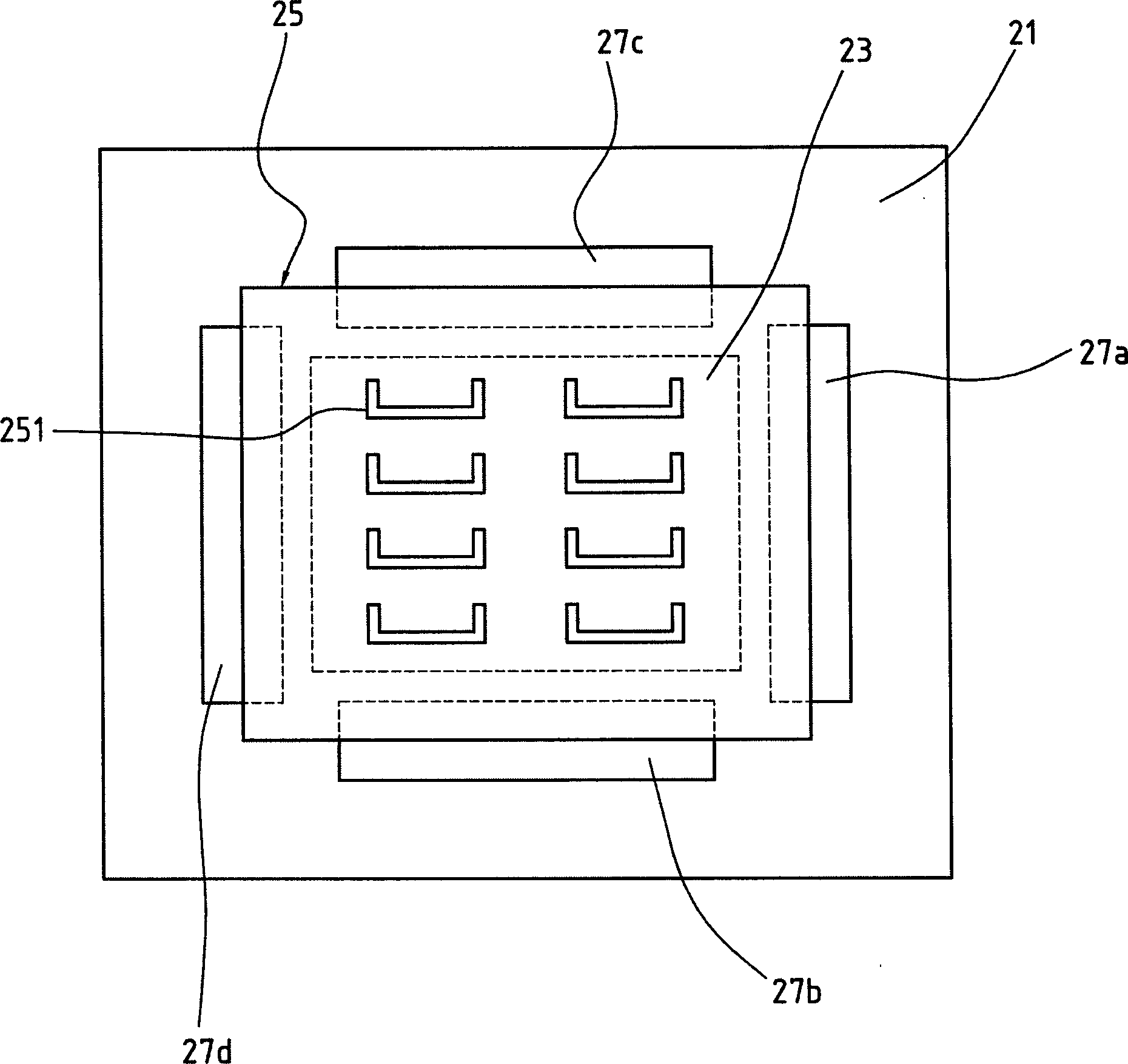

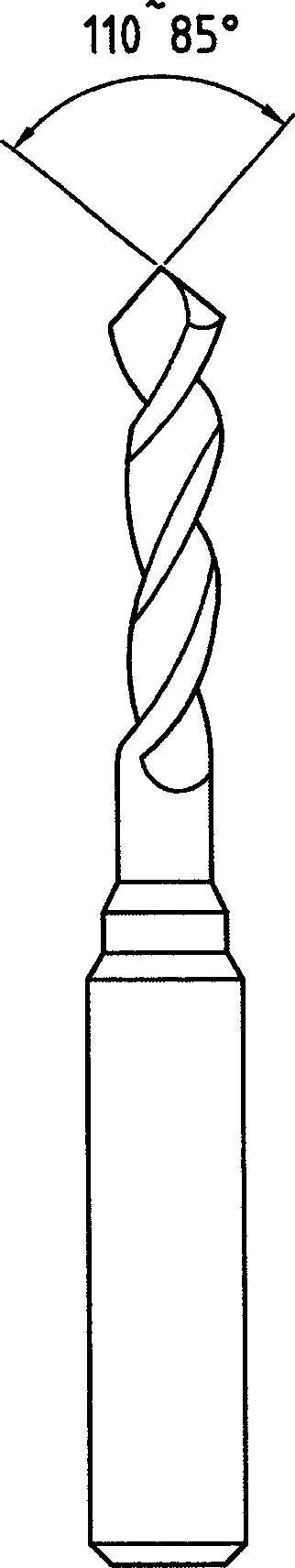

[0030] The present invention provides a processing method for adding a bevel after slotting in the layout of a multi-piece printed circuit board, which is to use a computer numerical control (CNC) tool machine with depth control to process the multi-piece printed circuit board. The beveled edge is added after slotting in the typesetting, and the burr on the cutting edge is removed at the same time when the beveled edge is cut, so that the multi-row printed circuit board after the treatment has a beveled edge structure. The method steps and structure are as follows figure 1 and Figure 4 shown. Step 11 is to provide a working pad, which is installed on the working table of the CNC machine tool to adjust the depth reference plane of the milling cutter. The working pad can be a plate with good surface polishing and flatness. Bakelite. St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com