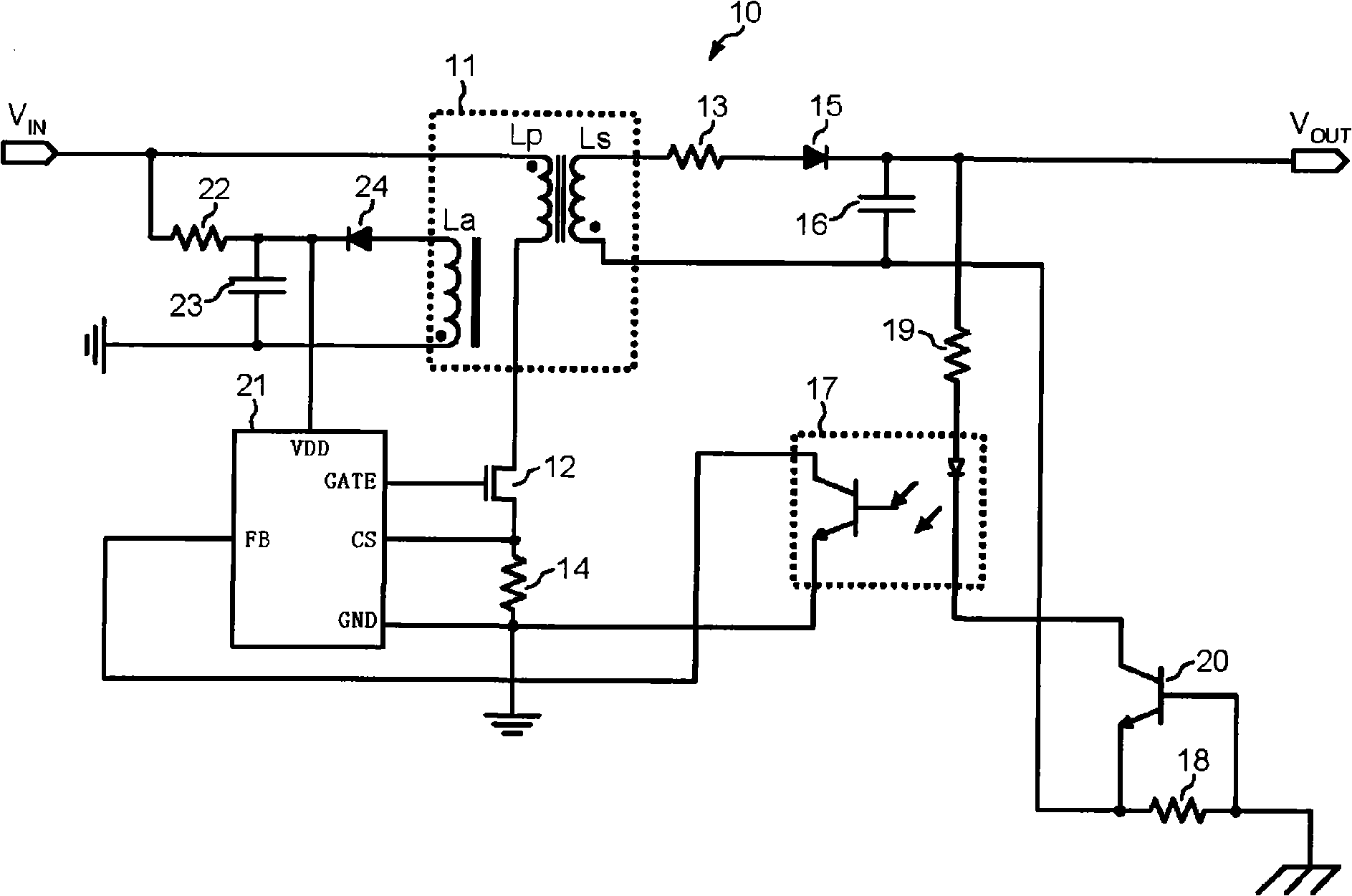

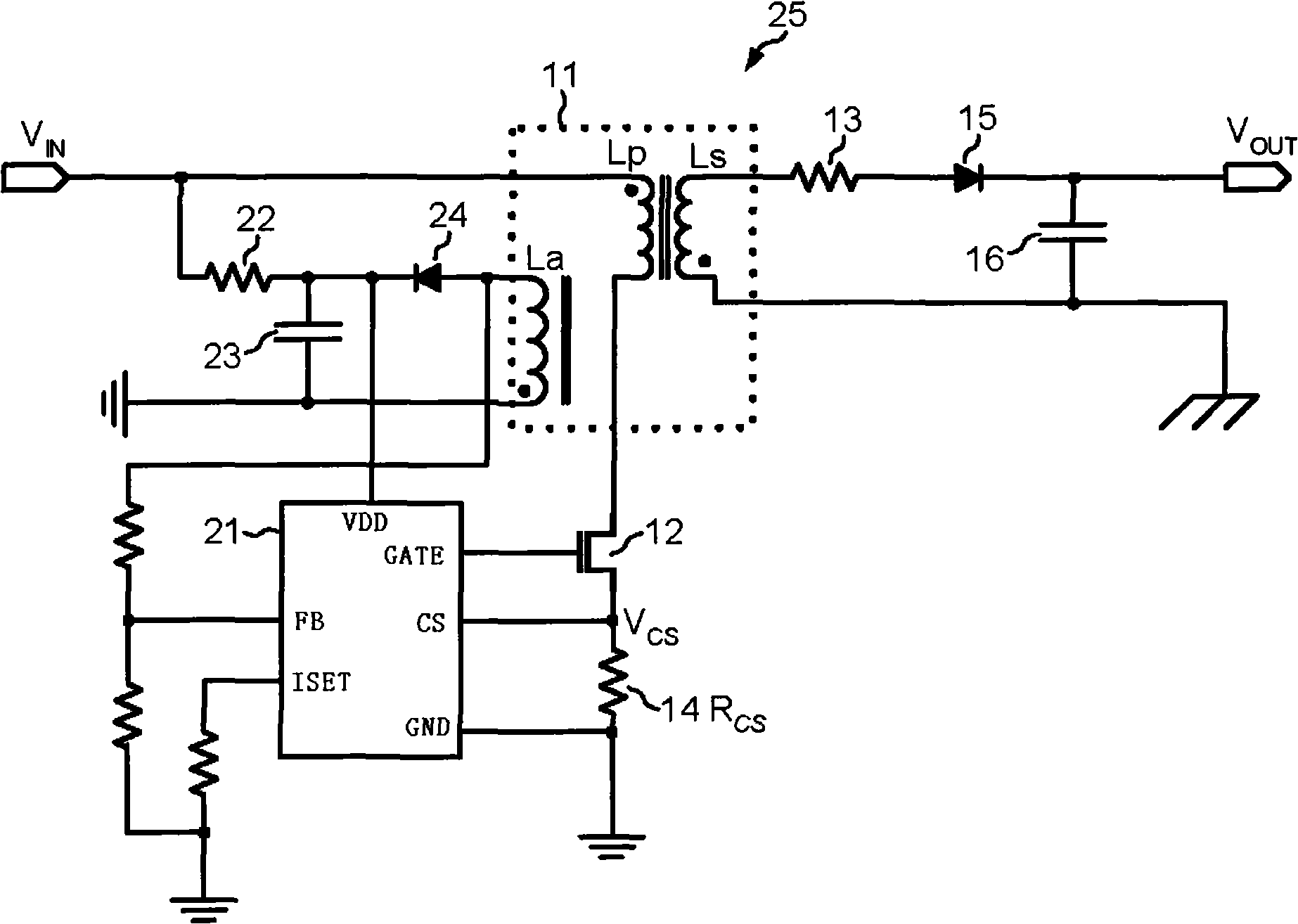

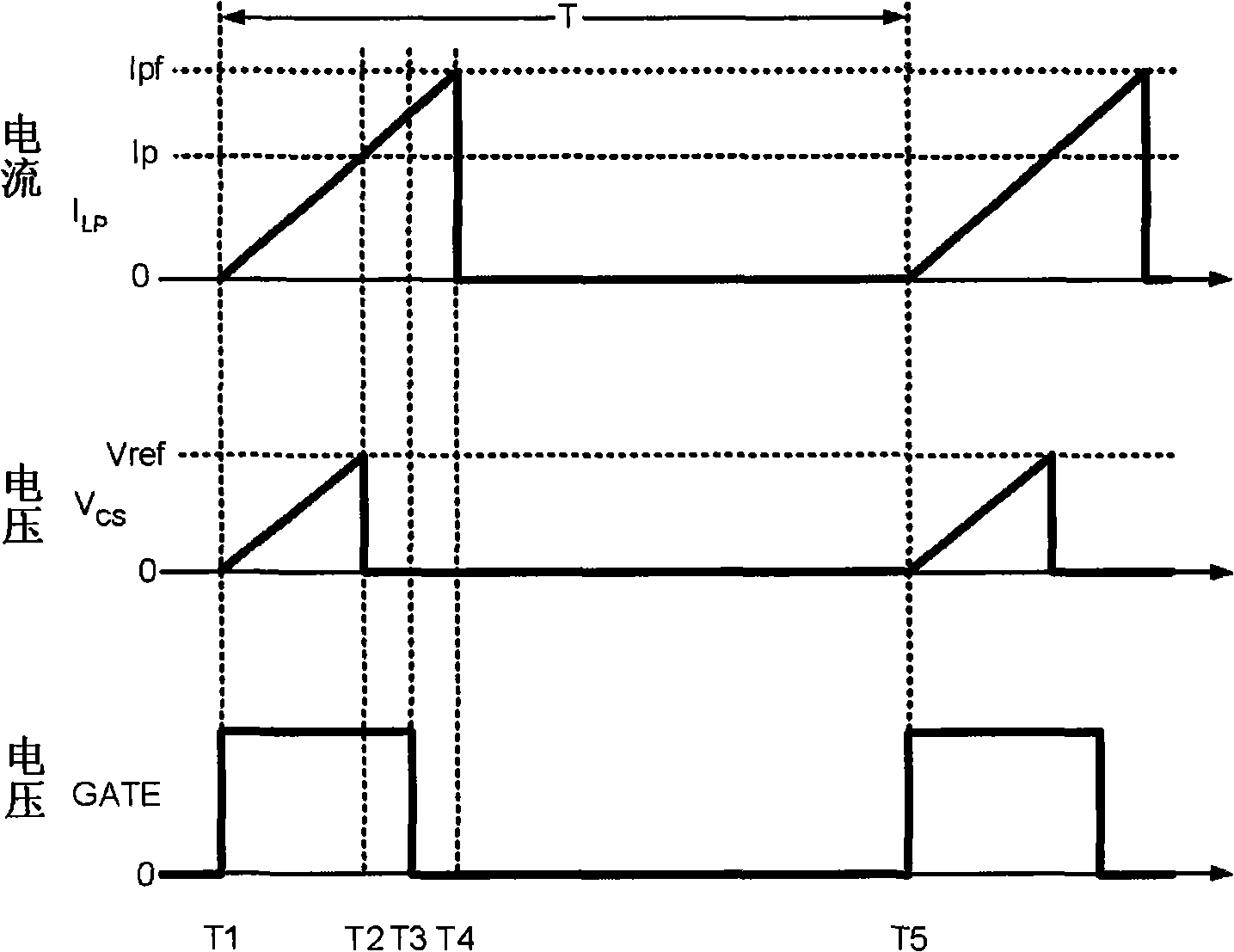

Primory feedback controller implementing high precision constant current output and method thereof

A controller and control signal technology, applied in the direction of output power conversion device, DC power input conversion to DC power output, control/regulation system, etc., can solve the problem of inaccurate output current and error of flyback converter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Unless otherwise stated, in this embodiment below, the inductive switch refers to the main power switch tube 44 , and the switch pin refers to the SW terminal or SW pin (that is, 99 in the drawings). For the convenience of expression and writing, the present invention adopts different technical terms for the same technical feature, but its substantive meaning or representative or pointed objects are the same, such as the so-called primary inductance (referring to the inductance on the primary winding or primary coil), The primary winding and the primary coil are all 39 in the accompanying drawings; for another example, the secondary inductance (referring to the inductance on the secondary winding or the secondary coil), the secondary winding and the secondary coil are also the same, all of which are 40 in the accompanying drawings; There are also auxiliary level inductance (refers to the inductance on the auxiliary winding, auxiliary level winding or auxiliary level coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com