Hybrid drive device

A hybrid drive and clutch technology, applied in power units, transmissions, gear transmissions, etc., can solve the problems of large shape, high cost, heavy weight, etc., and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

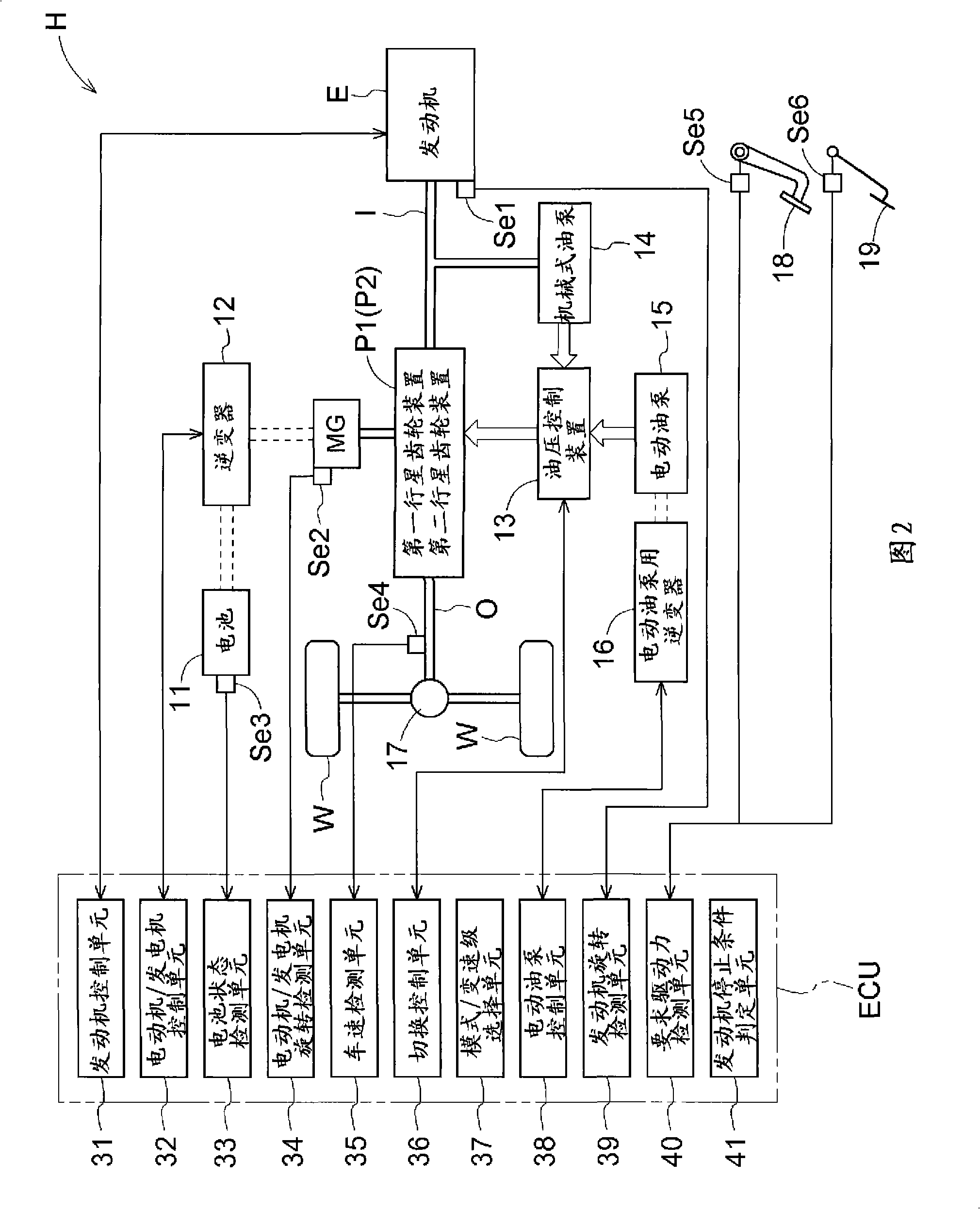

[0144] Next, a second embodiment of the present invention will be described. The hybrid drive device H according to the present embodiment has a configuration similar to that of the hybrid drive device H according to the above-described first embodiment, but has a configuration in which the parallel mode and the electric driving mode are further multi-staged, that is, in the parallel mode The lower includes the reverse stage, with 7 gear shifts, and in electric drive mode, with 3 shifts. Hereinafter, the hybrid drive device H according to the present embodiment will be described focusing on the differences from the above-described first embodiment. In addition, the system configuration of the hybrid drive device H according to the present embodiment is the same as that in FIG. 2 , and therefore, the description of this point is omitted. In addition, other structures are the same as those of the above-mentioned first embodiment unless otherwise specified.

[0145] 2-1. Config...

no. 3 Embodiment approach

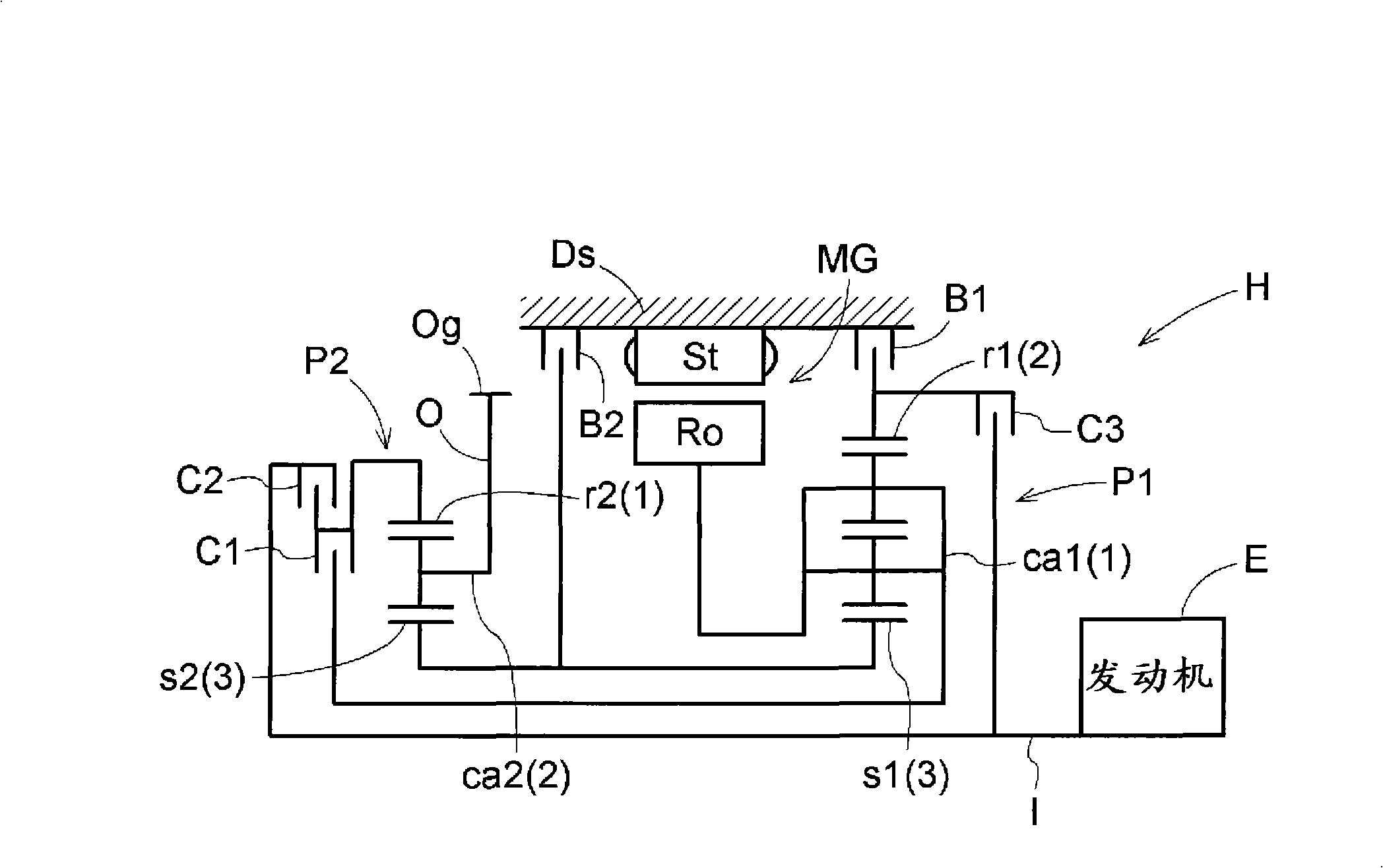

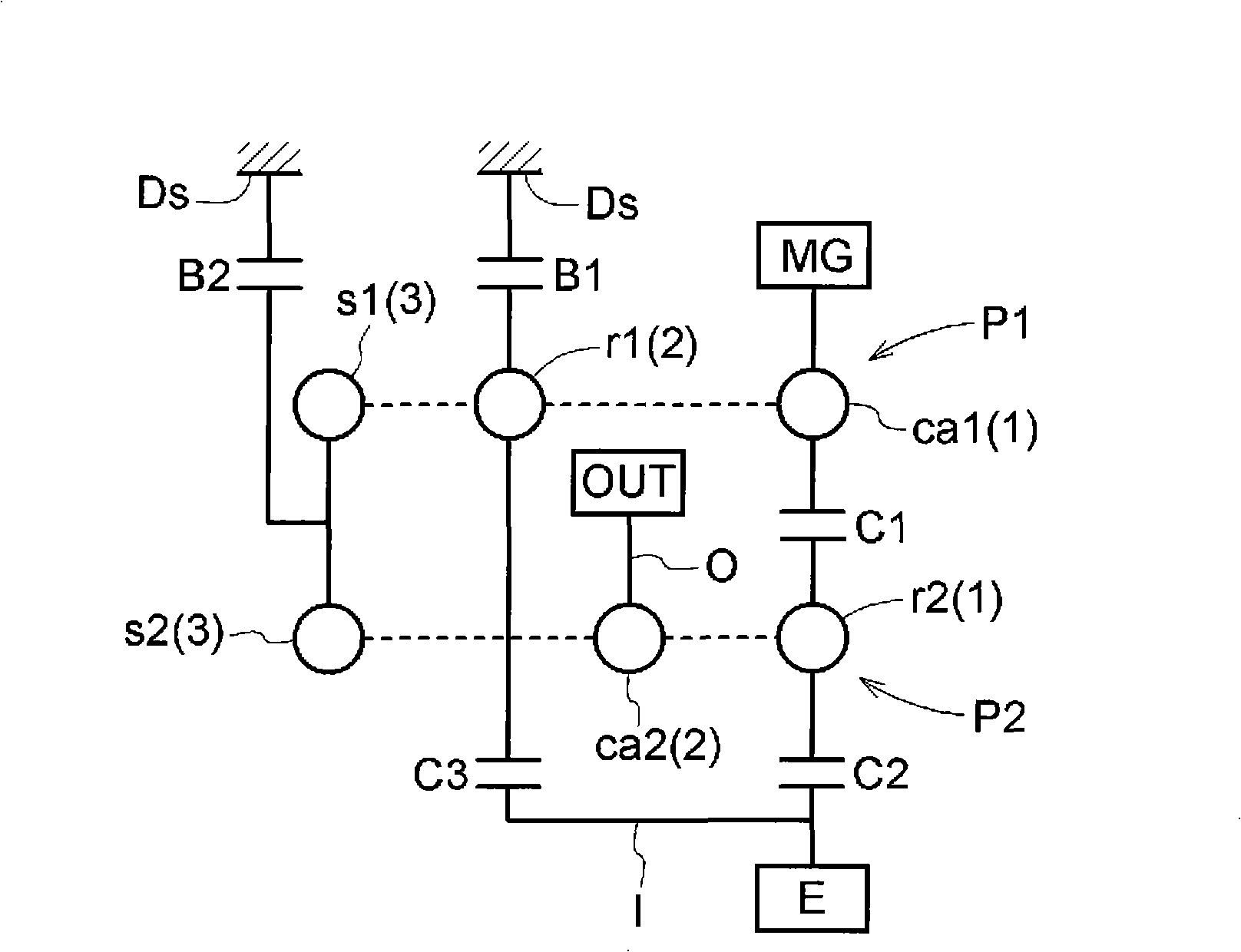

[0179] Next, a third embodiment of the present invention will be described. The hybrid drive device H according to the present embodiment is configured to integrally rotate the carrier ca1, which is the “second rotation member” of the first planetary gear device P1, and the carrier ca2, which is the “third rotation member” of the second planetary gear device P2. The ring gear r1, which is the "third rotating member" of the first planetary gear device P1, is selectively fixed to the case Ds by the first brake B1. This point is the same as the configuration of the first embodiment described above, that is, the "third rotating element (3) (sun gear s1)" of the first planetary gear device P1 and the "third rotating element (3) (sun gear s1)" of the second planetary gear device P2 The sun gear s2)" is integrally rotatably connected, and the "second rotation element (2) (ring gear r1)" of the first planetary gear device P1 is selectively fixed to the case Ds by the first brake B1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com