Assembling portion structure and assembling method of door or window decorative piece

An assembly method and technology for decorative parts, which are applied to vehicle parts, doors, sealing devices, etc., can solve problems such as deterioration of appearance quality, and achieve the effects of improving appearance quality, reducing assembly errors, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Next, an embodiment of the present invention will be described with reference to the drawings. In the following description, unless otherwise specified, up, down, front, and rear represent up, down, front, and rear of the vehicle body, respectively.

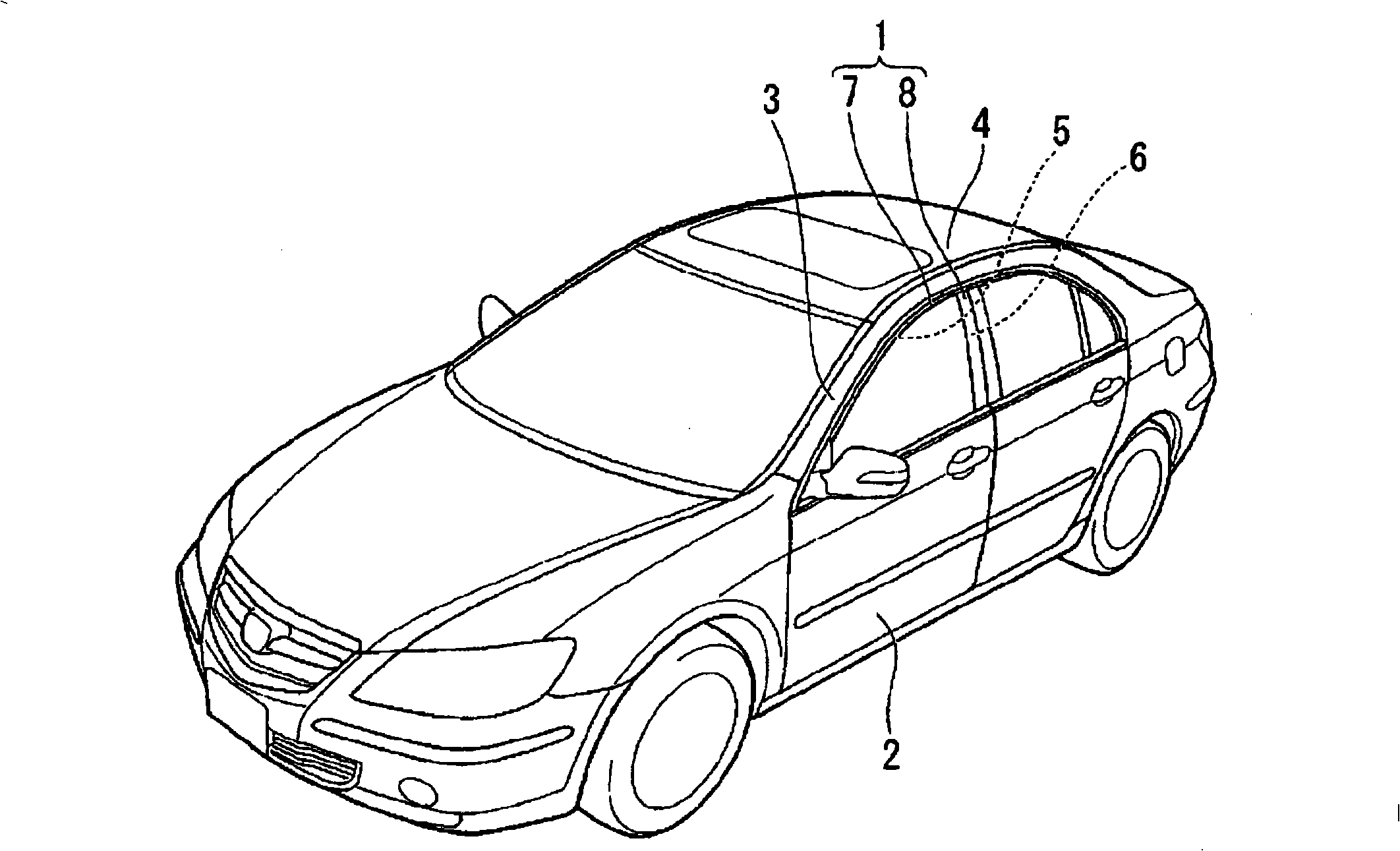

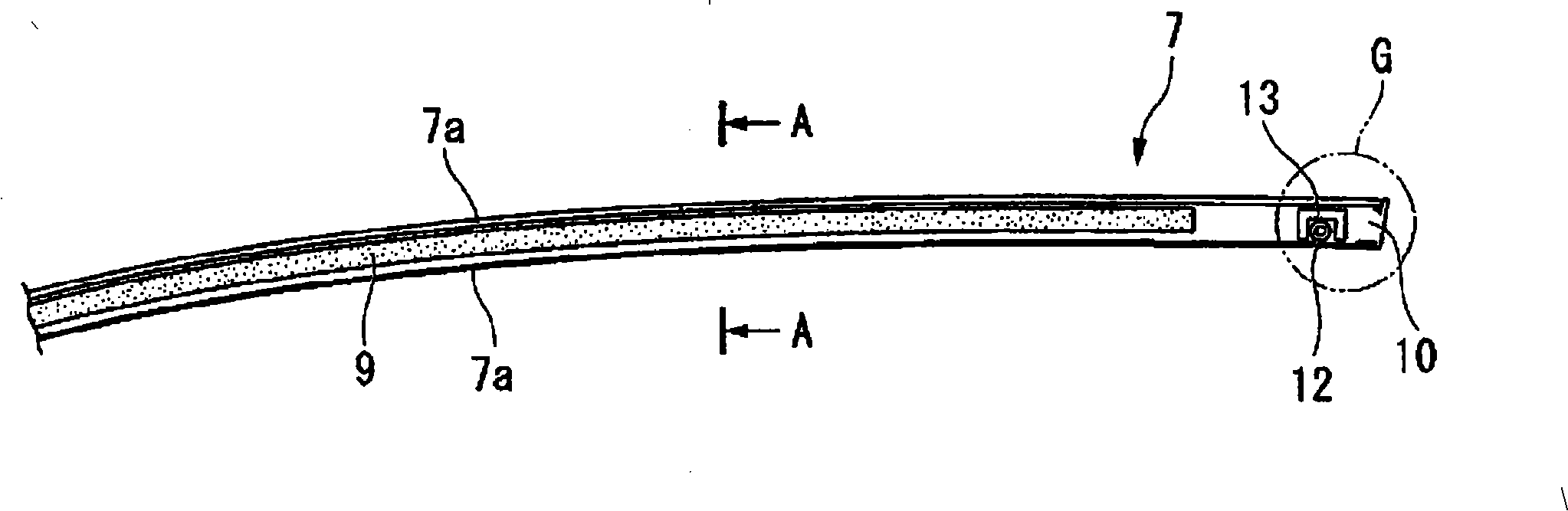

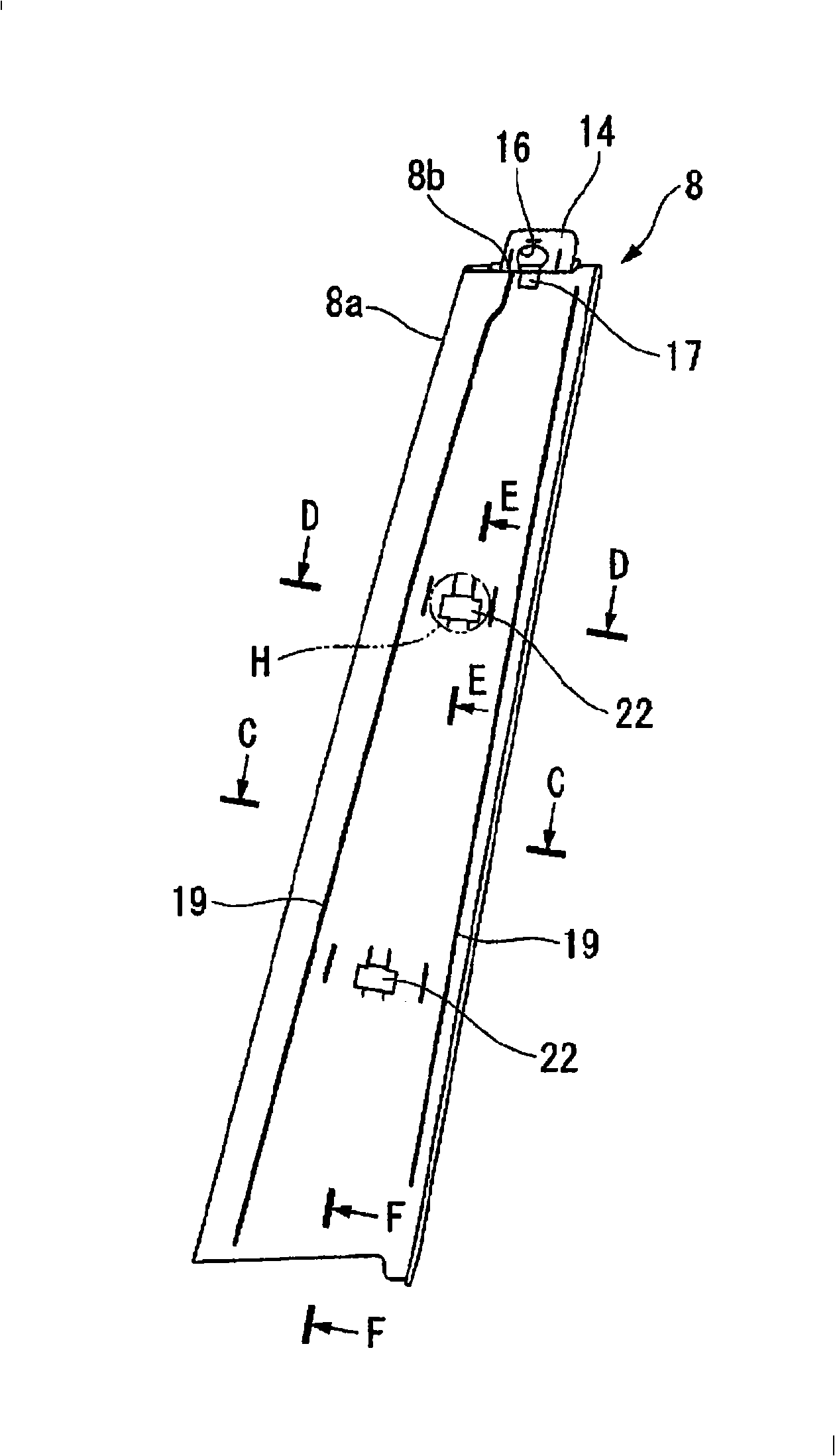

[0035] figure 1 Shown is a vehicle adopting the structure of the mounting part of the door sash trim 1 of the present invention, and the door sash trim 1 is mounted on the vehicle body outer surface of the door sash of the front door 2 . The door sash of the front door 2 includes a top-side sash portion 5 and a pillar-side sash portion 6, wherein the top-side sash portion 5 is located at the upper portion of the door, following the shape of the vehicle body side from the front pillar (A-pillar) 3 to the roof 4. Extending, the pillar-side sash portion 6 extends in the vertical direction at the center pillar (B-pillar) on the rear side of the door (front door 2 ). The door sash trim 1 includes a top side sash trim 7 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com