Structure of slant legged rigid frame bridge and cantalever pouring construction method

A technology of inclined legs and cantilevers, which is applied in infrastructure engineering, bridges, bridge construction, etc., can solve the problems of heavy superstructure weight, small spanning capacity, and large force on bridge pier foundations, so as to improve structural bearing efficiency and spanning capacity , good engineering economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

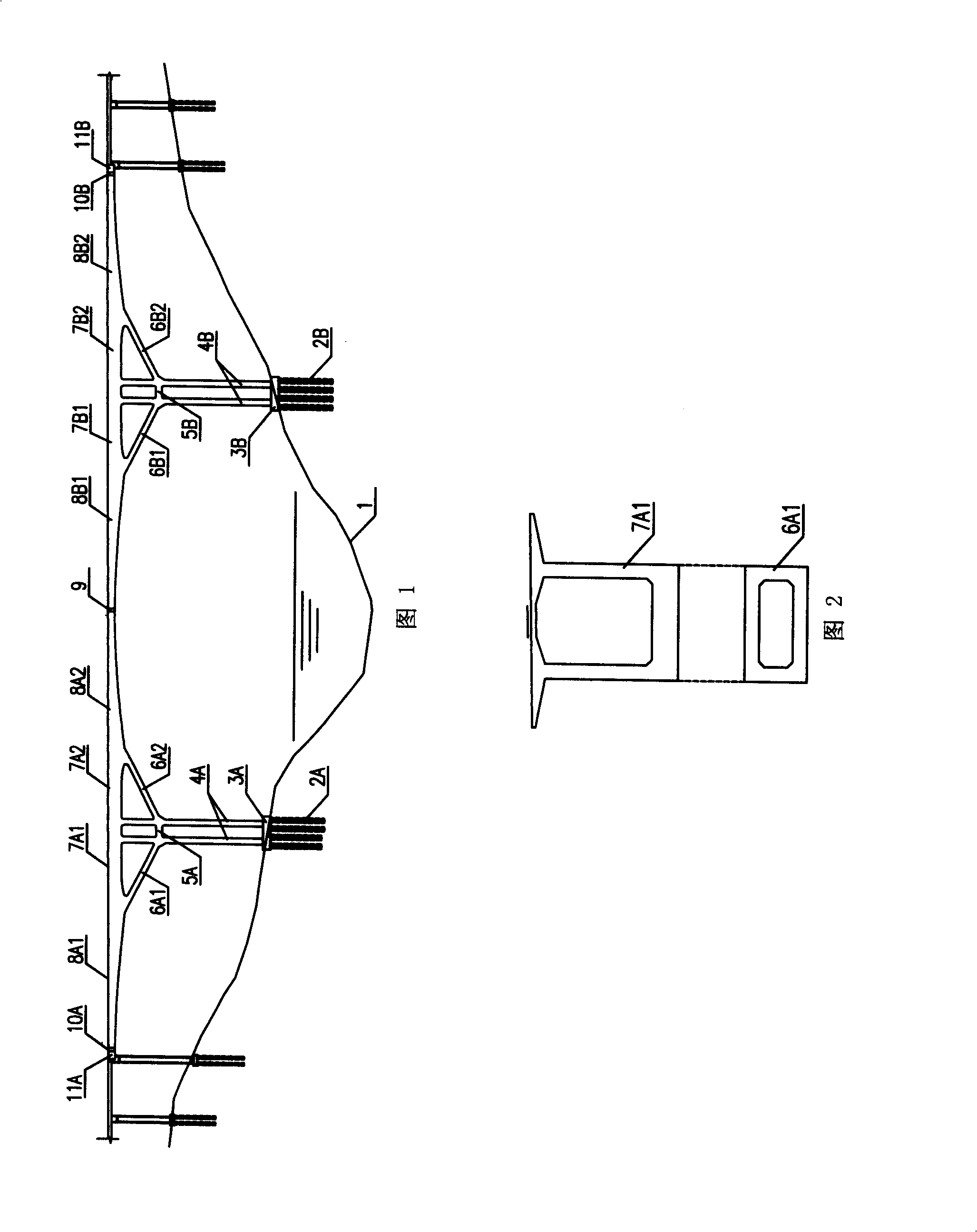

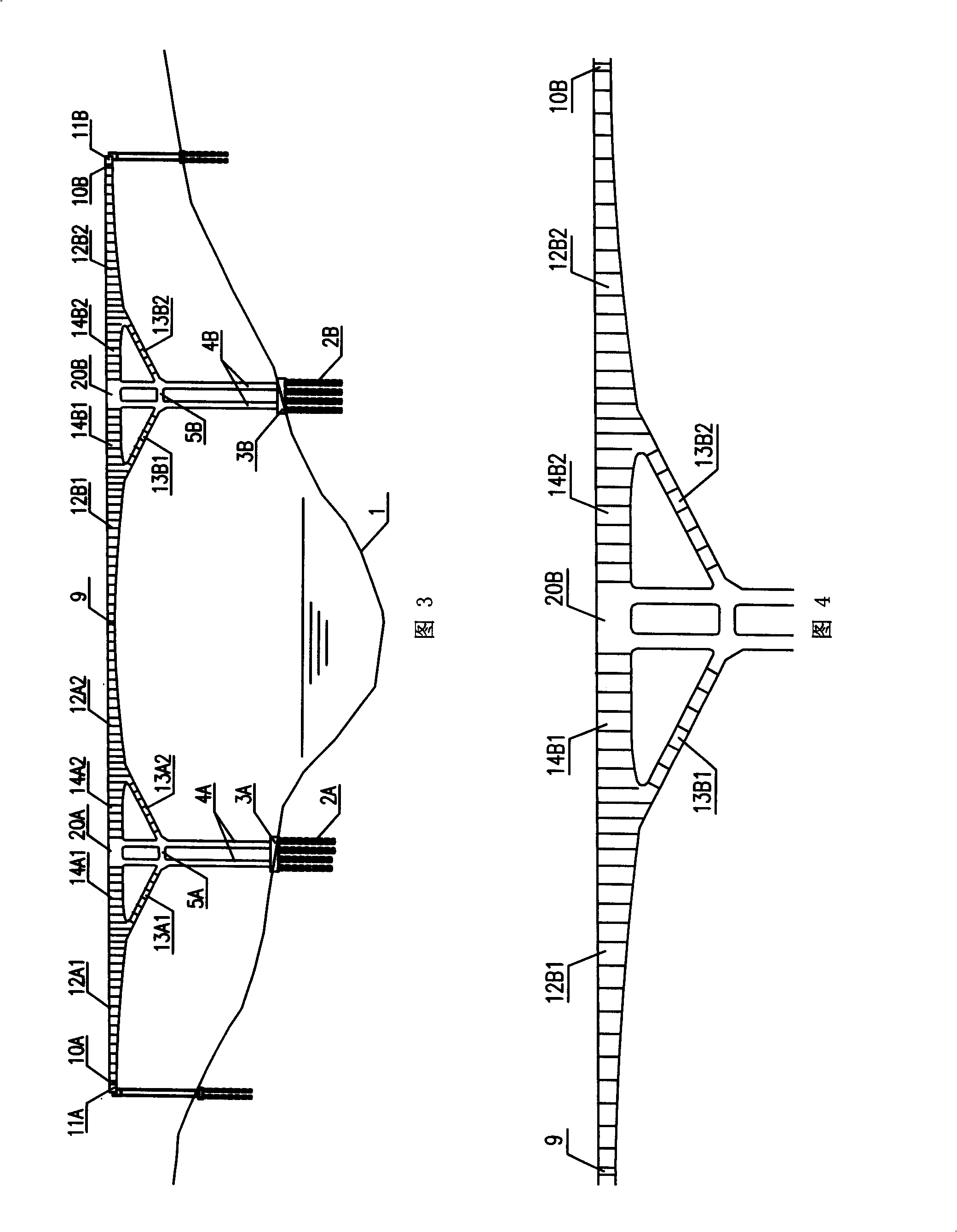

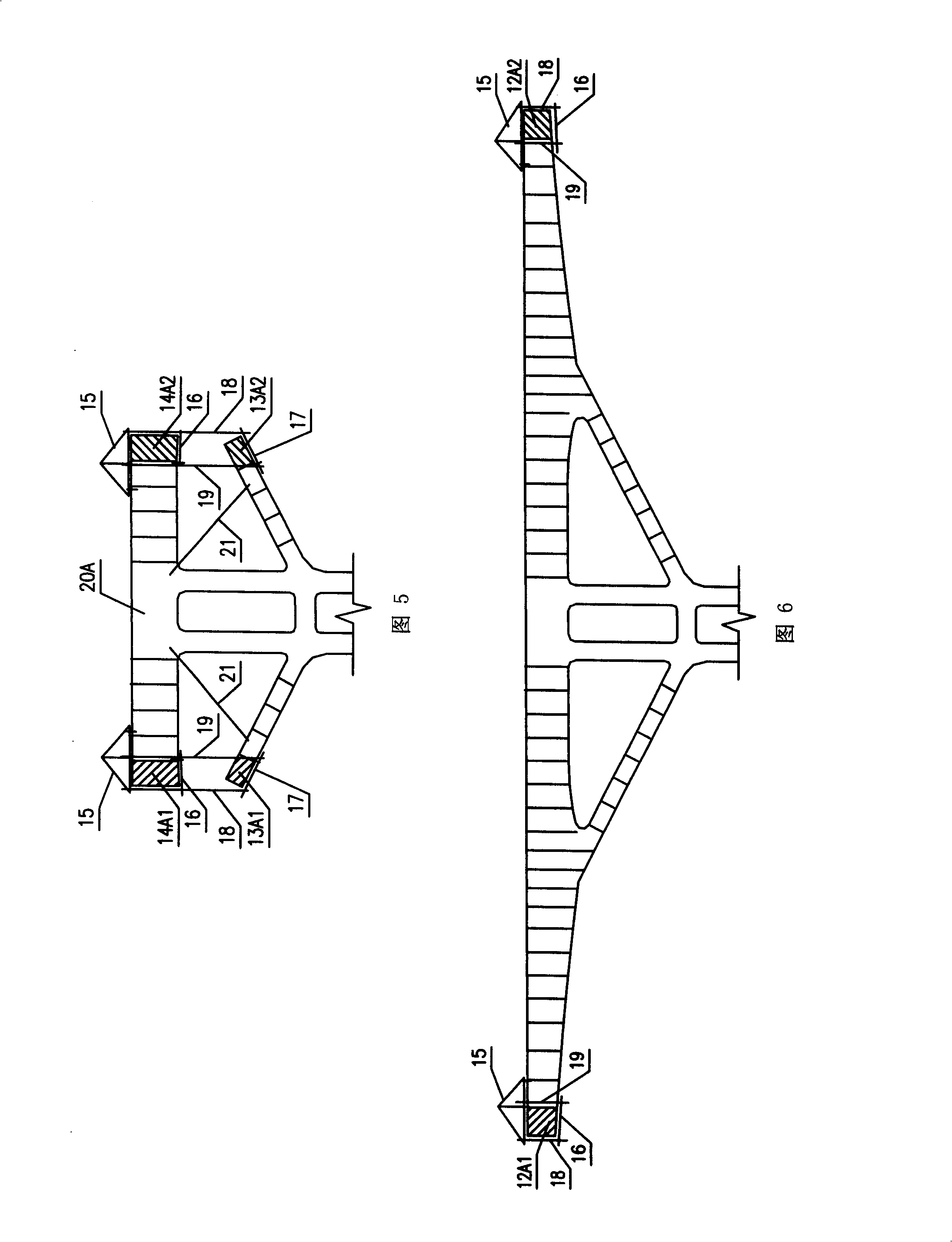

[0051] The implementation of the structural form of a kind of slanted leg (emptier type) continuous rigid frame bridge comprises:

[0052] 5. Reasonably determine the lengths of the lower strings (oblique legs) 6A1, 6A2, 6B1, and 6B2

[0053] The length of the lower chord (oblique leg) 6A1, 6A2, 6B1, and 6B2 should be comprehensively considered according to the force requirements of the cantilever construction of the lower chord, the compressive stress of the lower chord after the completion of the bridge, and the force requirements of the mid-span solid belly section, and optimized according to mechanical calculations , generally take 1 / 6~1 / 5 of the span L (distance between two adjacent piers).

[0054] 6. Reasonably determine the root truss height and the beam height of each section

[0055] The height from the root of the lower chord (oblique leg) 6A1, 6A2, 6B1, and 6B2 to the top of the girder—the height of the truss at the root, generally takes 1 / 10 to 1 / 8 of the span L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com