Full automatic silt separation apparatus

A fully automatic technology for sediment separation, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as failure of hydroelectric generating units, and achieve the effects of saving water, reducing siltation, eliminating hazards and abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

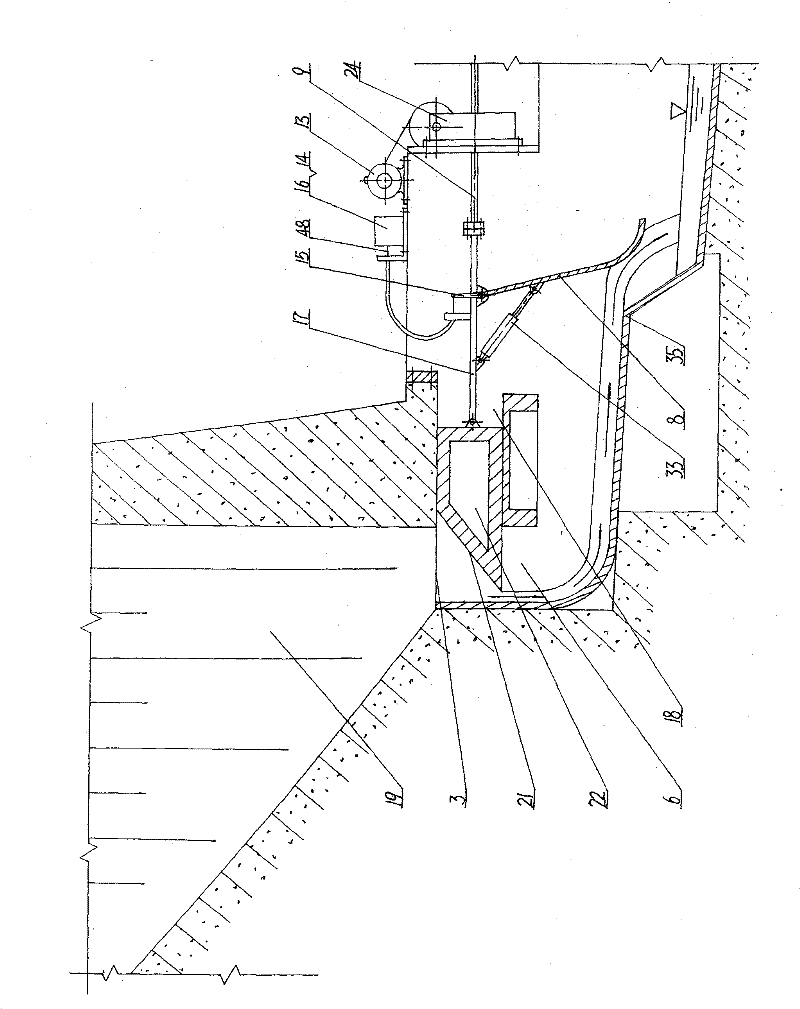

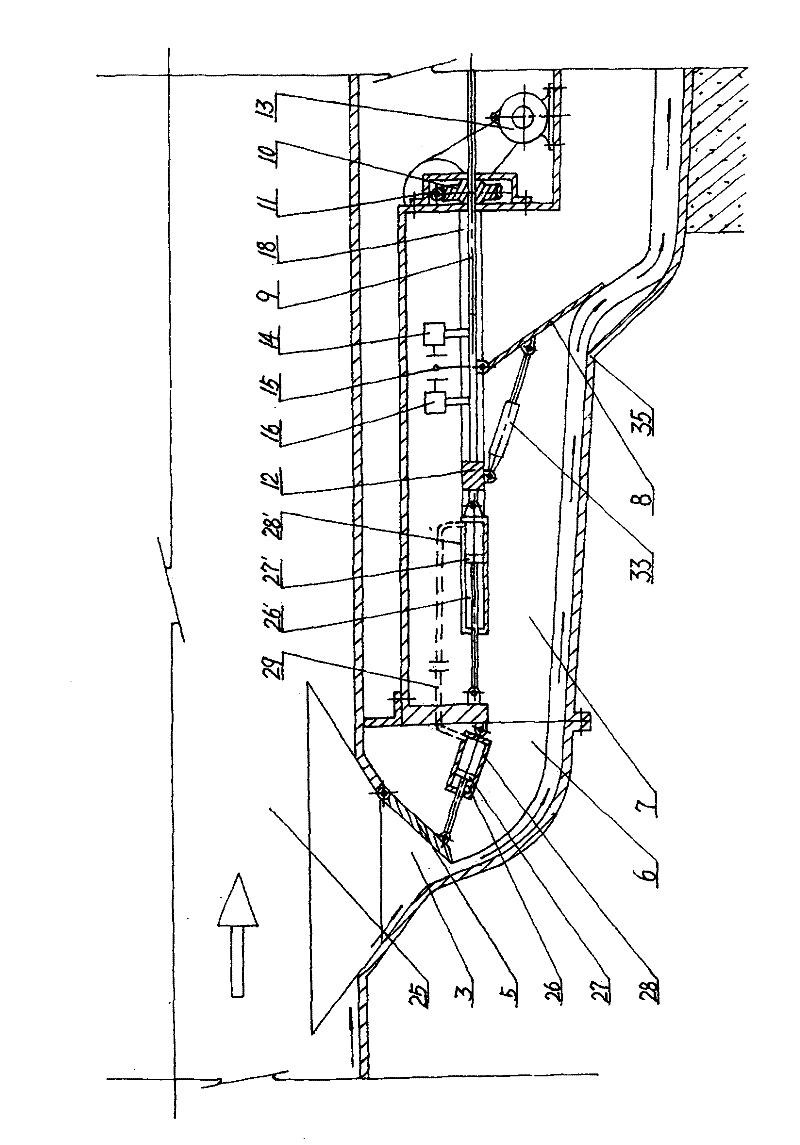

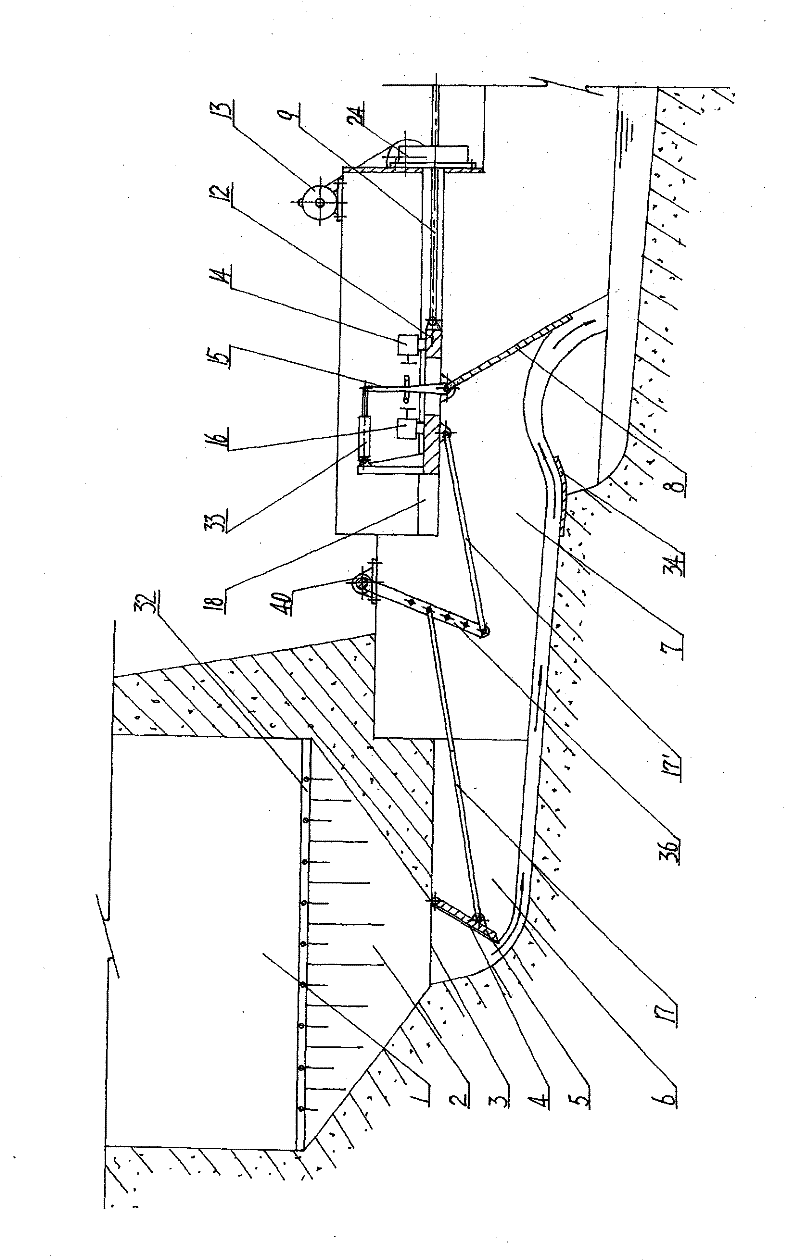

[0032] figure 1 A first embodiment of the invention is shown.

[0033] Such as figure 1 As shown: a trapezoidal groove 2 is developed at the bottom of the water diversion channel 1, and a rectangular sand discharge outlet 3 arranged horizontally is opened at the bottom of the trapezoidal groove 2, and a sand discharge flow channel 6 with a certain slope at the bottom is connected to the bottom of the rectangular sand discharge outlet 3 , the outlet end of the sand discharge channel 6 is connected to the falling water channel 7 provided with a pick-up ridge 34 . A trash rack 32 is arranged on the top surface level of the trapezoidal groove 2. A rectangular sand discharge throttling plate 5 is hinged on the edge of the rectangular sand discharge port 3 connected to the top surface of the sand discharge flow channel 6 , and seals 4 are arranged on both sides and the hinged end of the sand discharge throttle plate 5 . When the sand discharge throttling plate 5 hangs down, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com