Connector of rotary pressing pile

A technology of connecting parts and rotary pressing, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems that cannot be eliminated, the foundation is not fully compacted, etc., and achieve the effect of reducing the reduction of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

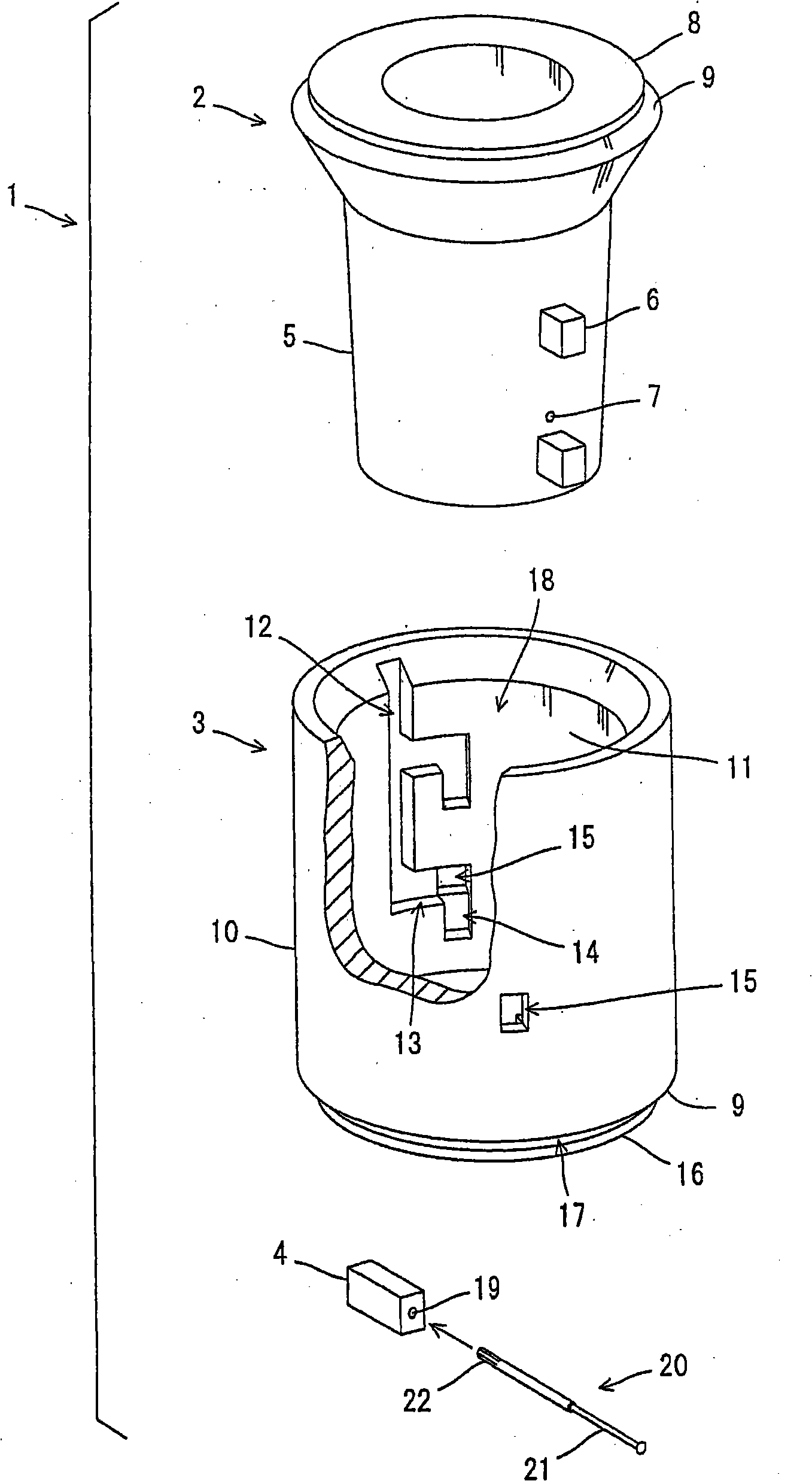

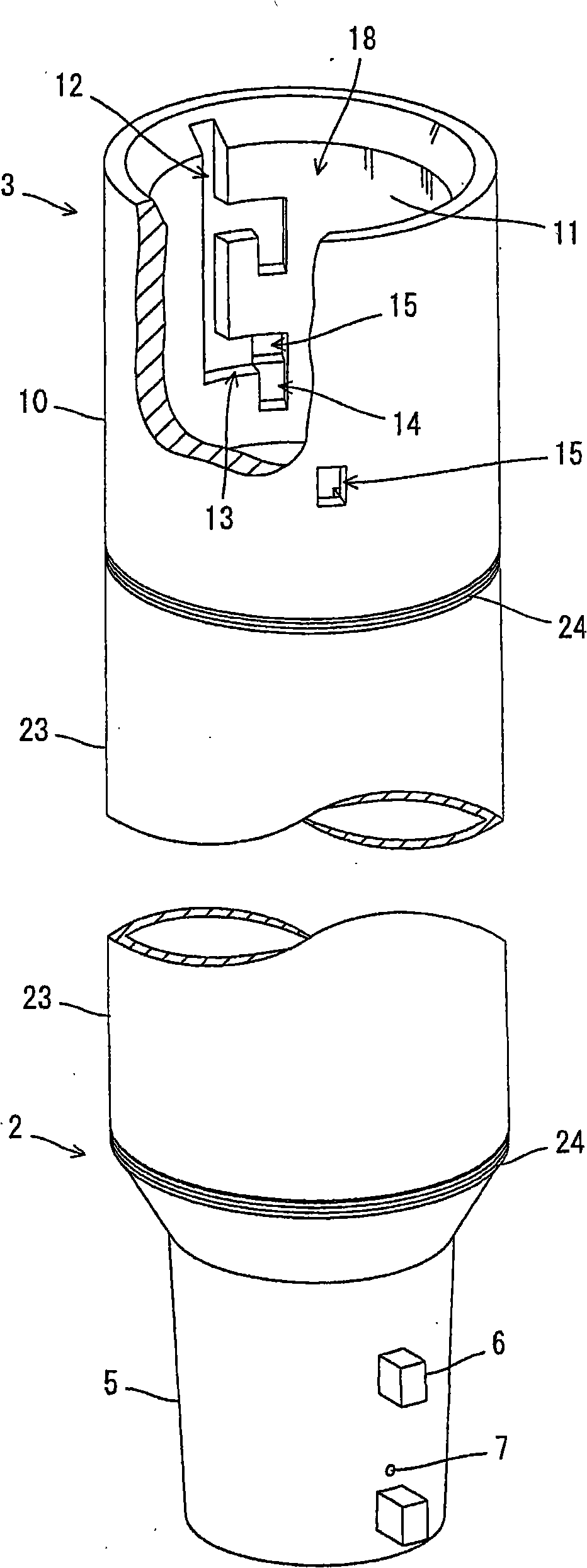

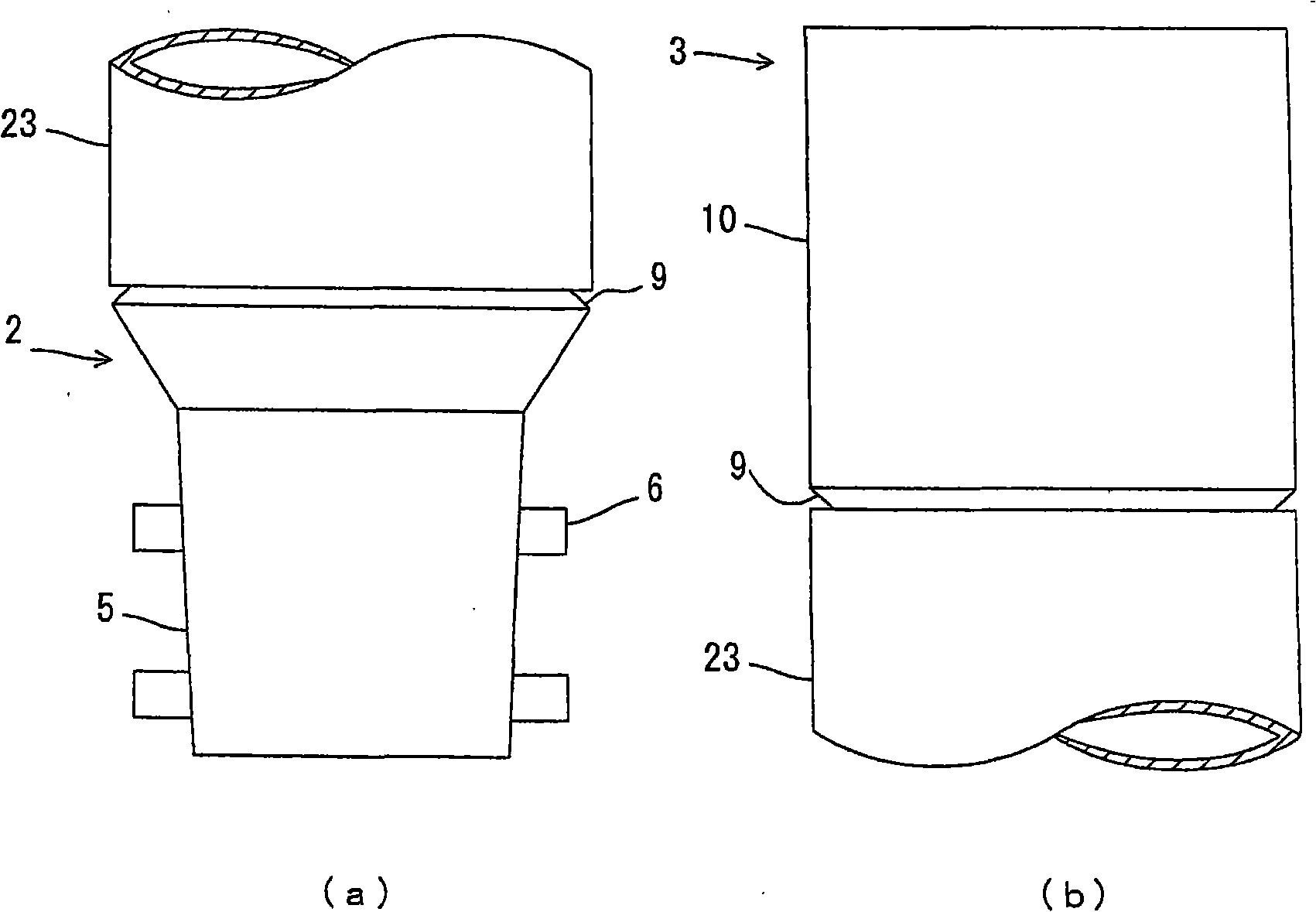

[0063] Next, the connecting member of the rotary press-in pile according to the present invention will be described with reference to the drawings.

[0064]Such as figure 1 As shown, the connection part 1 is composed of a male joint 2 connected to the lower end of the pile, a female joint 3 connected to the upper end of the pile, and an anti-extraction member 4 embedded in the window 15 of the female joint 3 .

[0065] On the outer periphery of the lower small-diameter portion 5, the male joint 2 is provided with an engagement protrusion 6 protruding in the radial direction with a rectangular cross-section, and has a fixed pin 20 passing through a through hole 19 of the pull-out preventing member 4 described later. The pin through hole 7 and the fitting small-diameter portion 8 as an attachment portion fitted to the end opening of the pile made of a steel pipe that is a rotary press-in pile. This fitting small-diameter part 8 has a structure which can be fitted inside when a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com