Adjustable energy-saving type constant temperature and humidity machine unit

A constant temperature and humidity, adjustable technology, applied in the direction of irreversible cycle compressors, refrigerators, compressors, etc., can solve the problems of energy waste, large heating capacity of heaters, and shortened service life of compressors, so as to avoid energy loss , save energy and prevent excessive heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

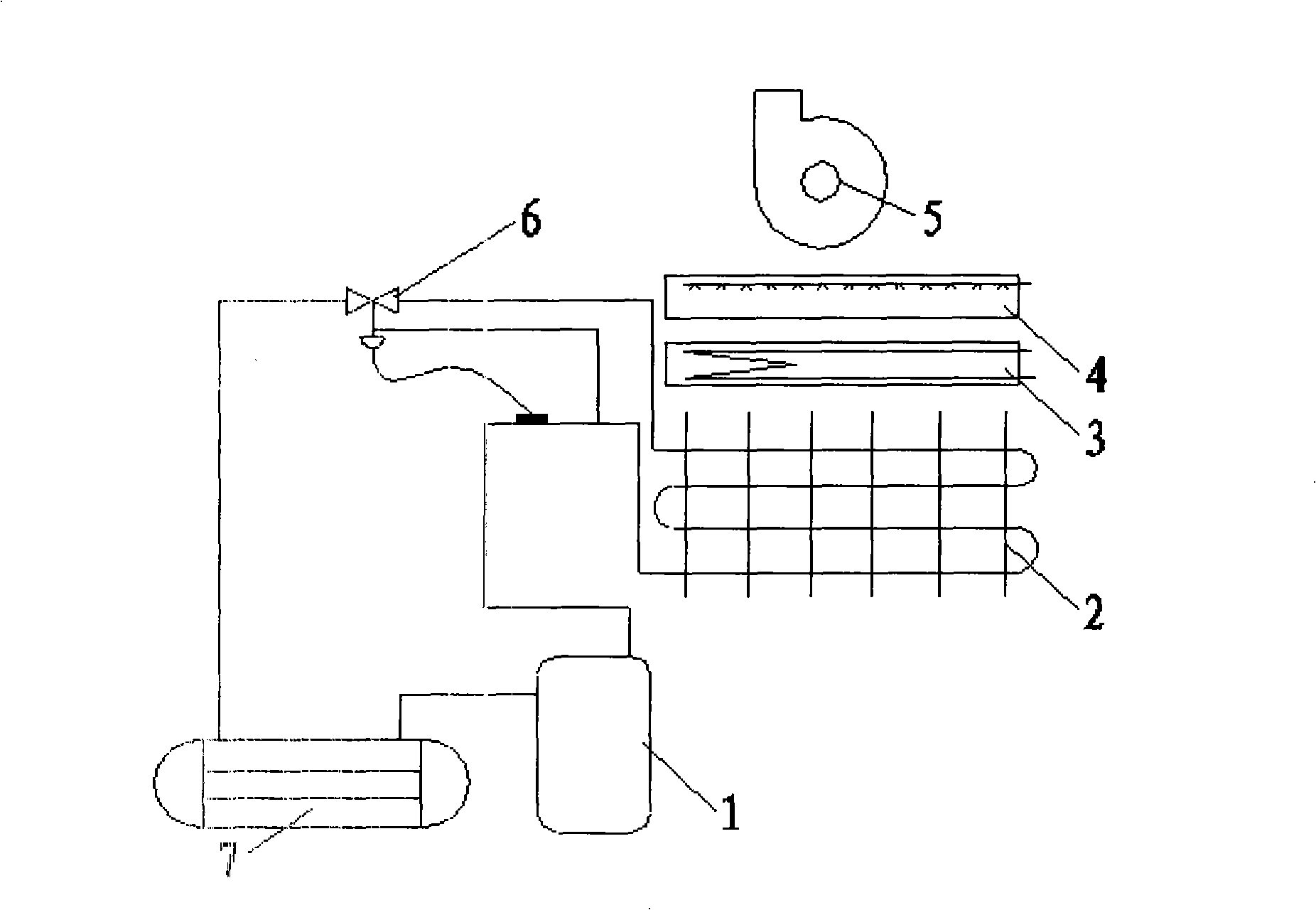

[0008] Such as figure 1 As shown, the present invention includes a frequency conversion compressor 1, an evaporator 2, a single-pipe adjustable heater 3, a steam adjustable humidifier 4, a centrifugal fan 5, a thermal expansion valve 6, and a condenser 7, and is characterized in that the frequency conversion compression The machine 1 is connected to the condenser 7, the condenser 7 is connected to the thermal expansion valve 6, the thermal expansion valve is connected to the evaporator 2, and the evaporator 2 is connected to the inverter compressor 1. In addition, a single-pipe adjustable heater 3, a steam adjustable humidifier 4 and a centrifugal fan 5 are connected next to the evaporator for processing the air. When the cooling load required by the unit is the largest, the frequency conversion compressor runs at full load, and if the load decreases, the compressor frequency conversion adjusts the output cooling capacity to match the corresponding load. When the heat load re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com