refrigerator

A technology for refrigerators and frost boxes, which is applied to household refrigeration devices, defrosting, lighting and heating equipment, etc. Thermal effects, reduced workload, effects of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

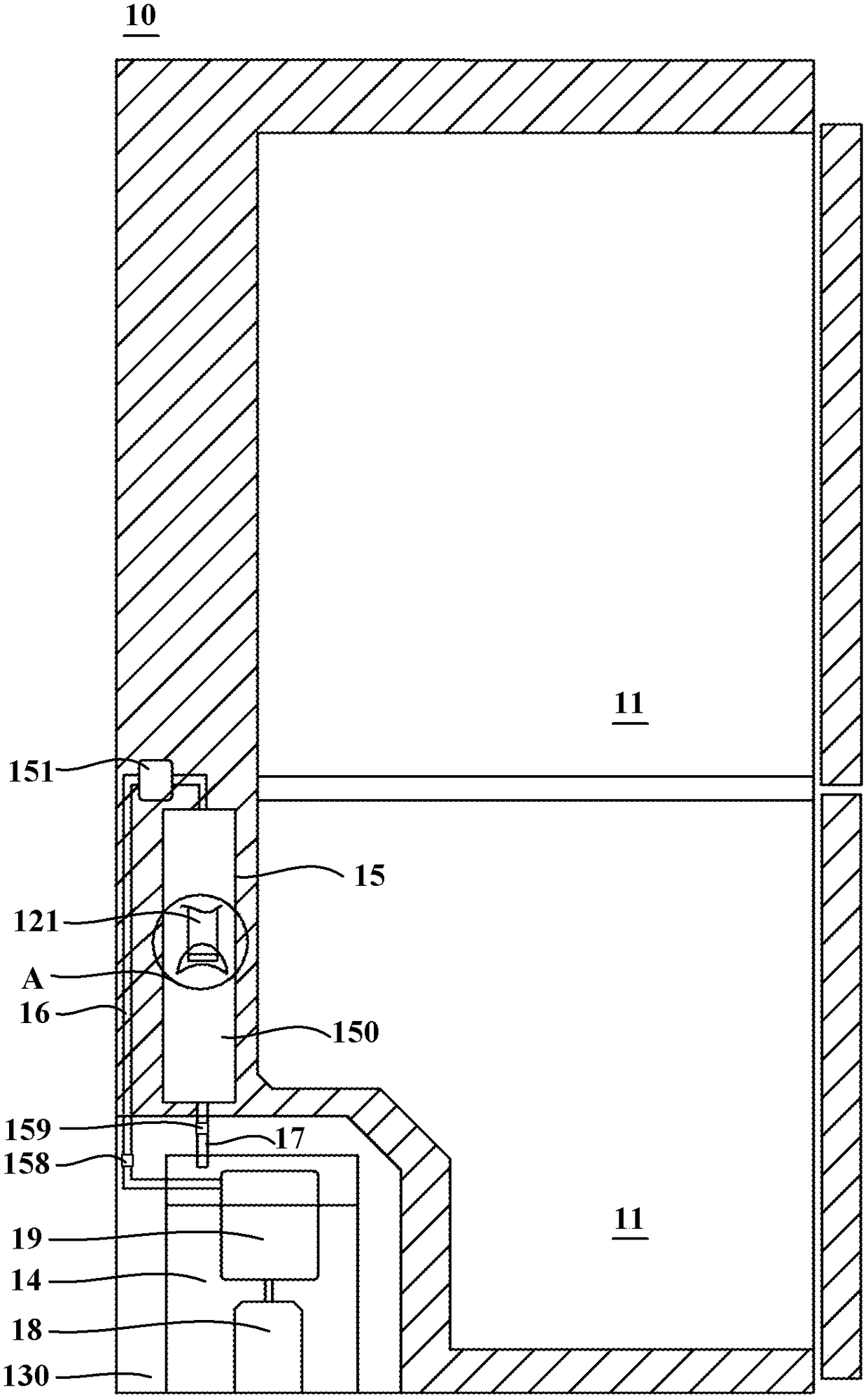

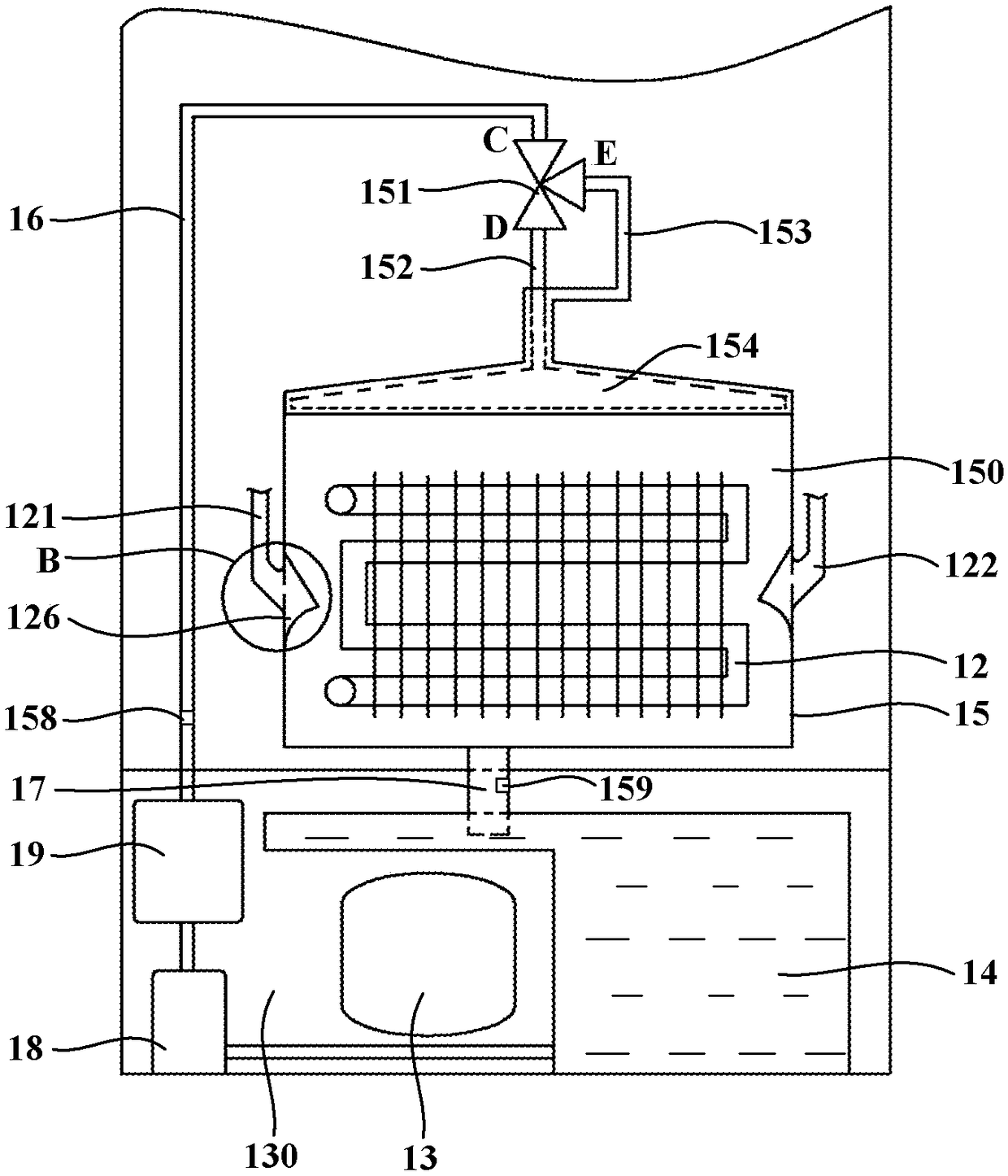

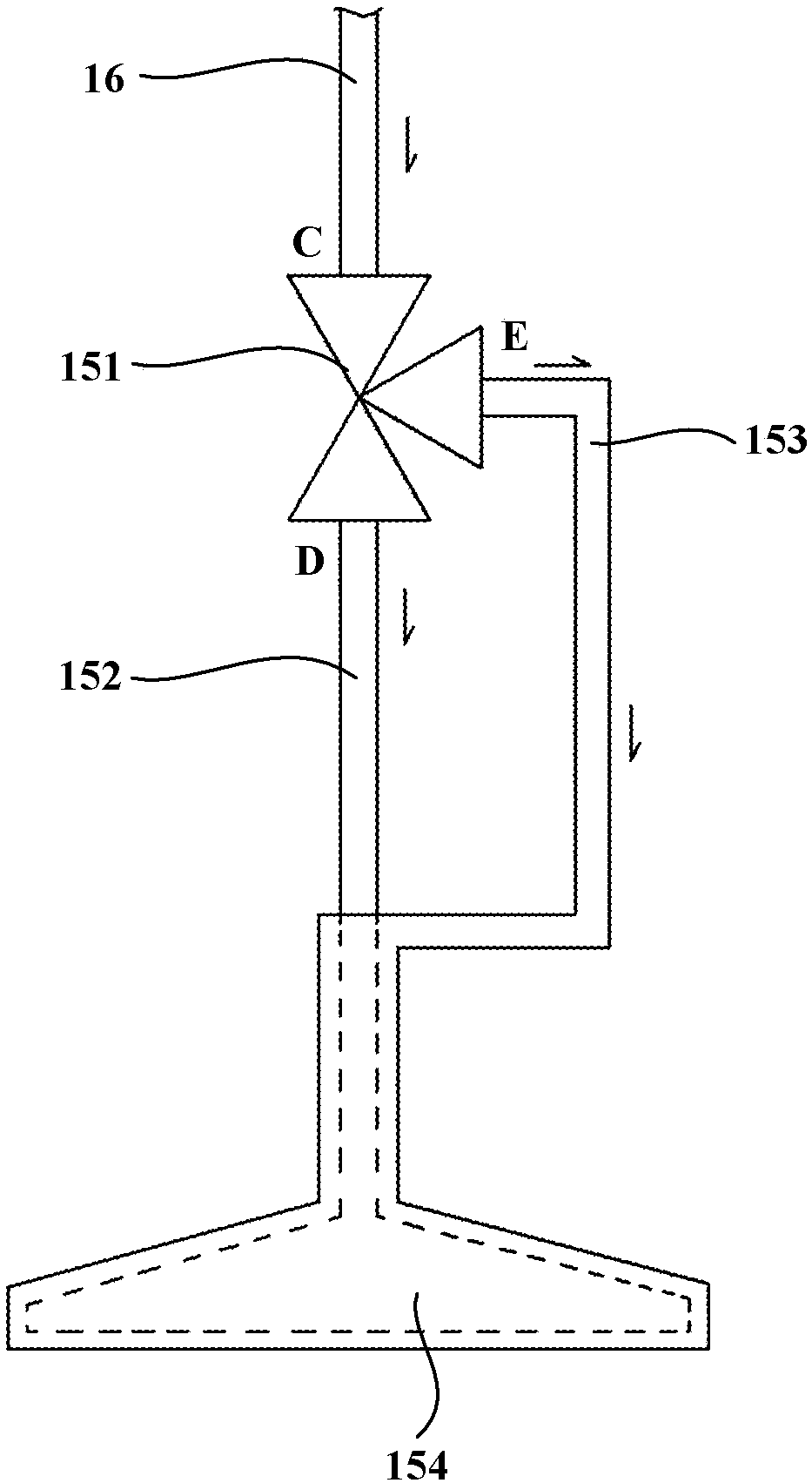

[0044] figure 1 is a schematic side view of a refrigerator 10 according to an embodiment of the present invention; figure 2 yes figure 1 A partial rear perspective view of the refrigerator 10 in FIG. see figure 1 and figure 2 , the refrigerator 10 of the embodiment of the present invention may include a storage compartment 11 and an evaporator 12 for providing cooling capacity to the storage compartment 11 . figure 1 The illustrated refrigerator 10 has two storage compartments 11 , and in an unillustrated embodiment, the refrigerator 10 may also have only one storage compartment 11 or more than two storage compartments 11 . As can be appreciated by those skilled in the art, in addition to the evaporator 12, the refrigerator 10 of the embodiment of the present invention is the same as the existing indirect refrigerator, and may also include a compressor 13, a condenser (not shown in the figure) and a compressor. Flow elements (not shown in the figure), etc. The evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com