Motor provided with holding structure for radial bearing

A technology for electric motors and bearings, applied in the field of electric motors, can solve problems such as radial vibration of the rotating shaft, increased shaking, and increased vibration, and achieve the effects of preventing radial vibration, suppressing deformation of the inner diameter, and high coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the motor of the present invention will be described in detail below with reference to the drawings.

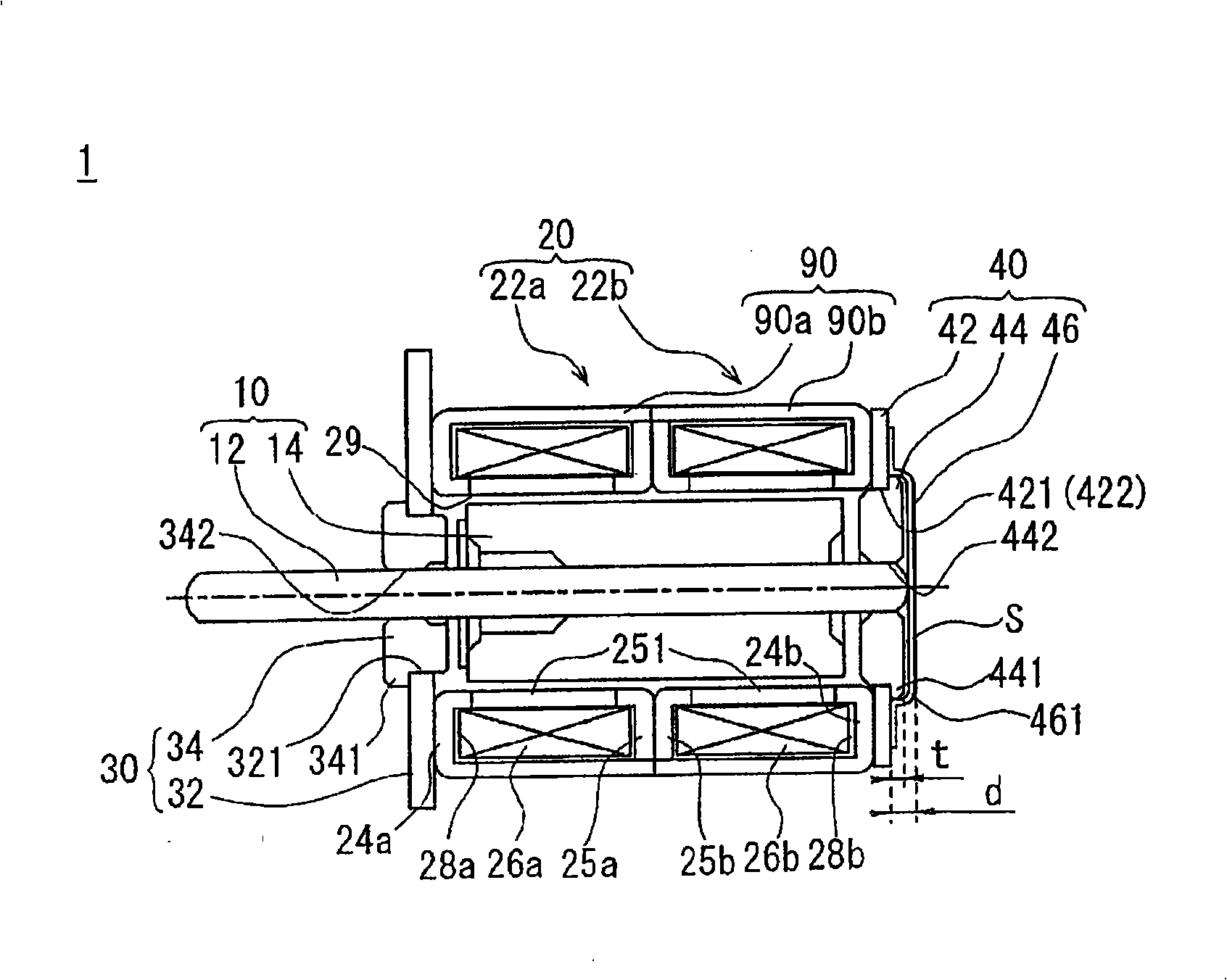

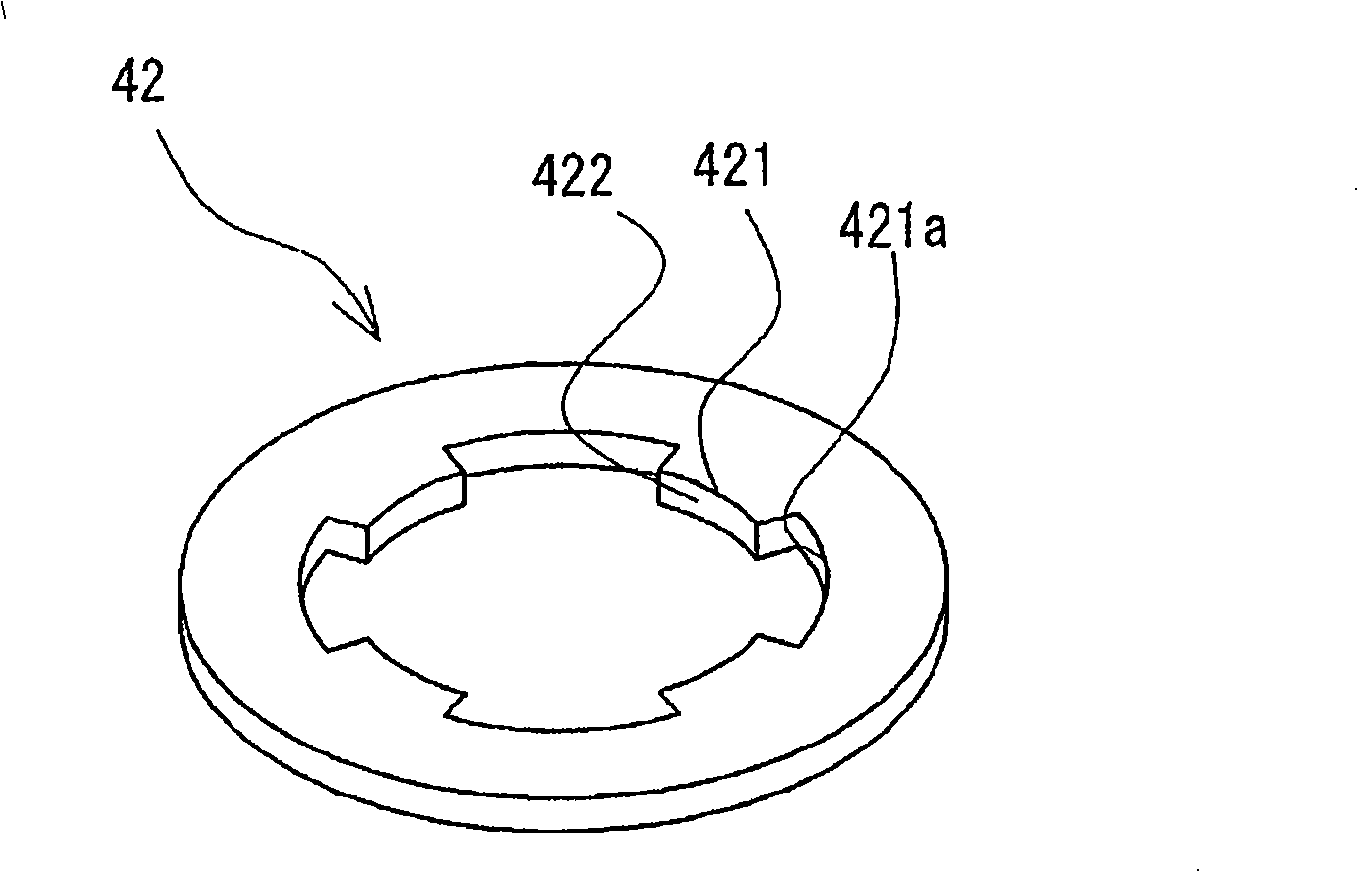

[0050] figure 1It is a sectional view of the motor 1 of this embodiment. The motor 1 of the present embodiment includes: a rotor 10, a stator 20, a first bearing part 30, and a second bearing part 40, wherein the first bearing part 30 is formed by a first bearing part rotatably supporting the rotor 10 on the output side of the motor 1. A radial bearing 34 and the first plate 32 that is fixedly connected to the output side end face of the stator 20 to install the first radial bearing 34 are formed, and the second bearing part 40 is formed by placing the rotor 10 on the anti-output side of the motor 1 (with the output The second radial bearing 44 rotatably supported on the opposite side of the stator 20 , and the second plate 42 fixedly connected to the end surface of the stator 20 on the opposite output side to mount the second radial bearing 44 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com