Shaft member for dynamic pressure bearing device

A technology for dynamic pressure bearings and shaft components, which is applied in the direction of bearing elements, sliding contact bearings, and rotating bearings, etc., and can solve the problem of depth or shape deviation of dynamic pressure grooves, inability to exert sufficient dynamic pressure, and decreased accuracy of outer peripheral surfaces, etc. problem, to achieve the effect of superior wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

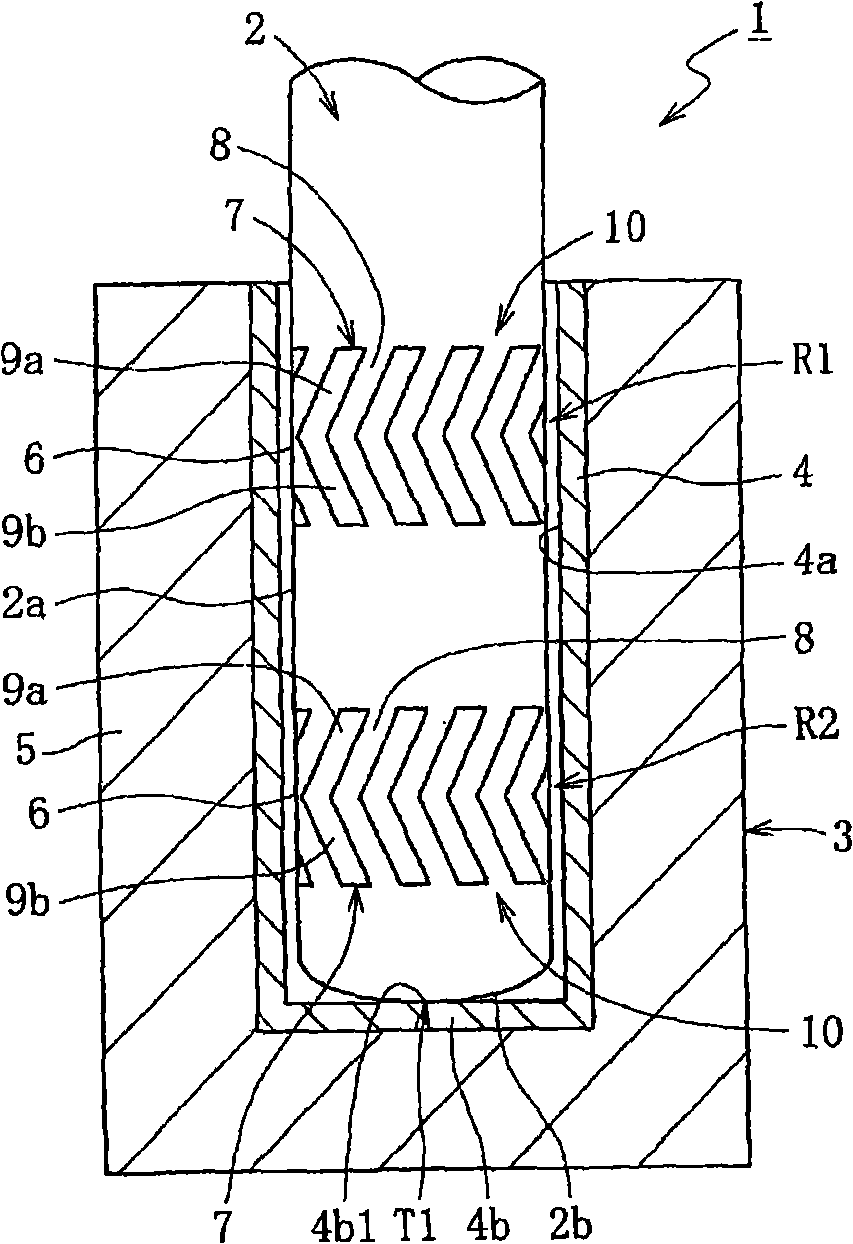

[0067] figure 1 A sectional view showing the dynamic pressure bearing device 1 of the first embodiment. In this figure, a dynamic pressure bearing device 1 includes a shaft member 2 and a bearing member 3 capable of inserting the shaft member 2 into the inner periphery.

[0068] In this embodiment, the bearing member 3 is a bottomed cylindrical body composed of an electroformed part 4 and a molded part 5, and the electroformed part 4 integrally or separately from the main body (master) is used as an insert part by integral injection molding of resin. The inner peripheral surface 4a of the electroformed portion 4 facing the outer peripheral surface 2a of the shaft member 2 has a perfect circular shape.

[0069] The shaft member 2 has a shaft shape with a constant diameter, and is made of, for example, a highly workable metal material (about 300Hv to 400Hv in terms of hardness) such as carbon steel, stainless steel, and various alloy steels. Of course, it is also possible to u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com