Sealing method of wind import and export of reduction distilling furnace and rapid sealing closure

A technology for the air inlet and outlet and distillation furnace, which is applied in the sealing field of the inlet and outlet of the reduction distillation furnace, which can solve the problems of poor sealing reliability, impact on production capacity, and long time required for the installation of the cover, so as to achieve product quality and production capacity guarantee, and stable sealing performance Reliable, low operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the examples, but not as a limitation to the present invention.

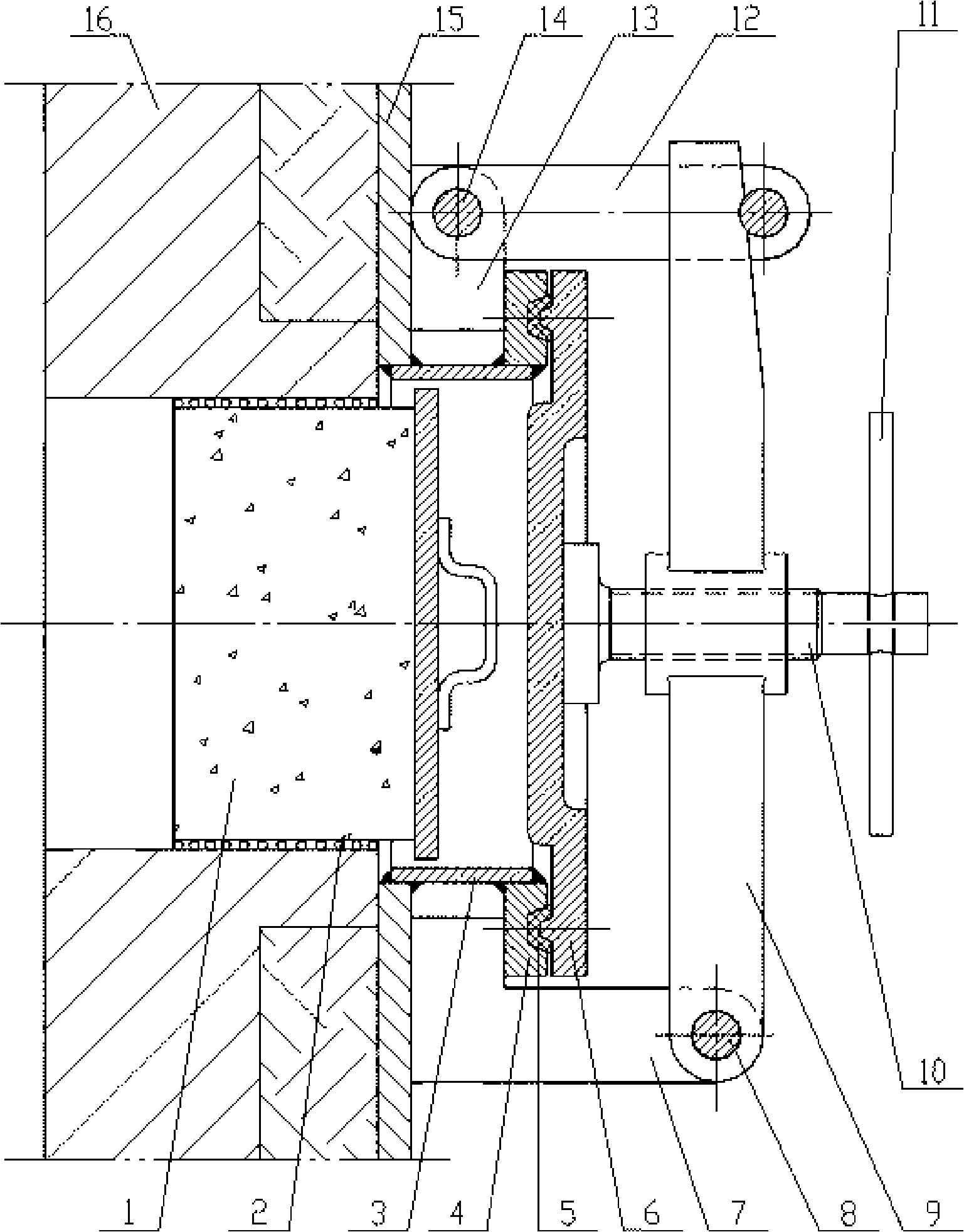

[0013] Embodiment of the present invention: when adopting the sealing method of the air inlet and outlet of the reduction distillation furnace of the present invention to seal the air inlet and outlet of the reduction distillation furnace, an air inlet and outlet mask that can cover the air inlet and outlet is first fixed at the air inlet and outlet of the existing reduction distillation furnace. Then use the inner cover to block the air inlet and outlet, set the rubber sealing ring on the port of the steel pipe, and then press the gland tightly on the rubber sealing ring, so that a gap is formed between the inner cover and the gland. Confined space, so promptly complete the sealing work to the air inlet and outlet of reducing distillation furnace.

[0014] During implementation, it is preferable to adopt the technical sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com