Super-resolution compound shade differential confocal measuring device and method

A measuring device and differential confocal technology, applied in the field of ultra-precision measurement, can solve the problems of inability to perform correction, difficult processing, and high installation and adjustment requirements, achieve common mode interference suppression, easy engineering application, and large axial response range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

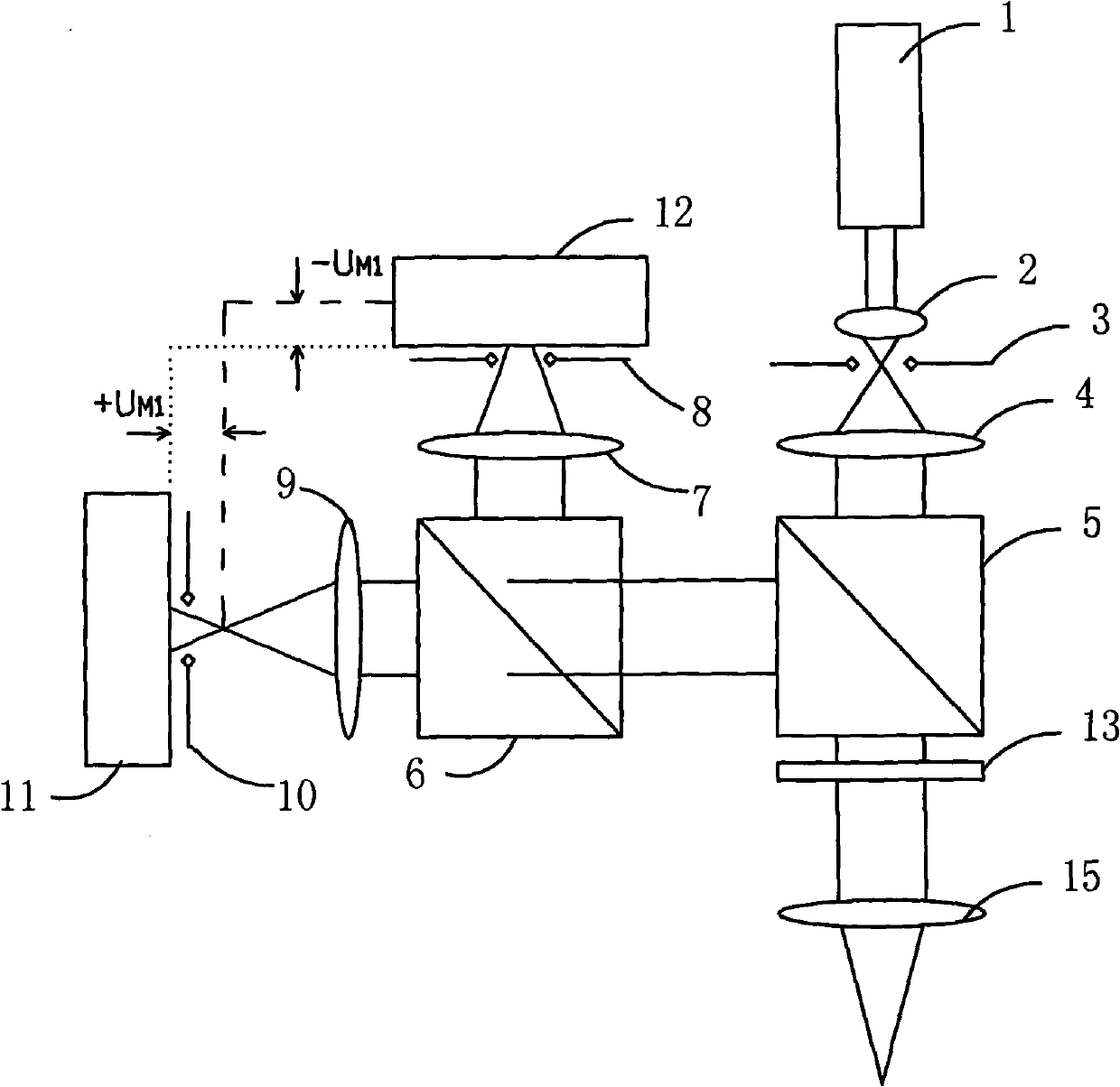

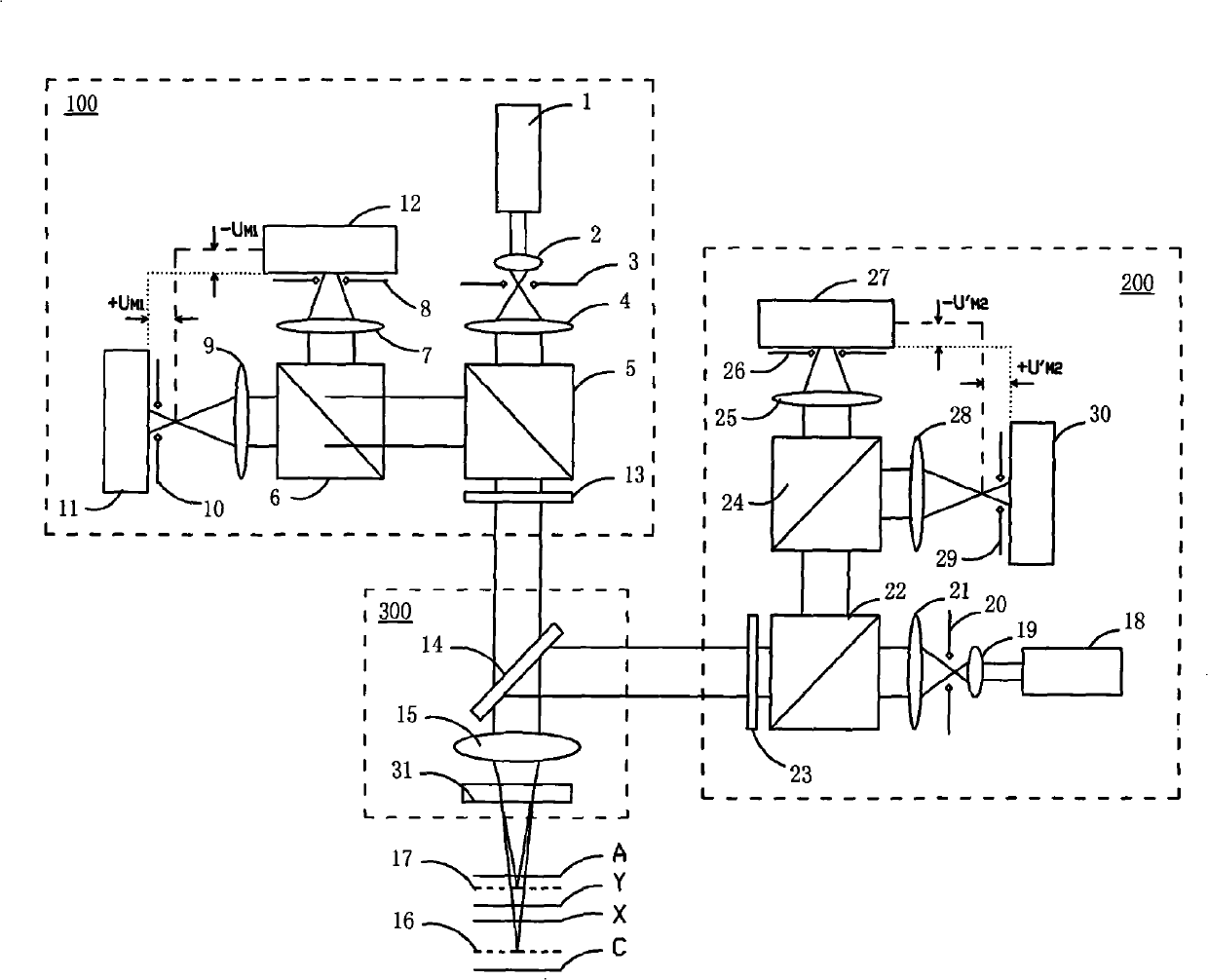

[0026] refer to image 3 , the super-resolution polychromatic differential confocal measurement device based on parallel plate chromatic aberration correction of the present invention includes a first differential confocal measurement device 100 , a second differential confocal measurement device 200 and a parallel plate corrected chromatic aberration super-resolution probe 300 .

[0027] The first differential confocal measurement setup 100 includes an emission wavelength λ 1 The first laser 1, the first collimating and focusing objective lens 2, the first pinhole 3, the first collimating beam expanding objective 4, the first polarizing beam splitter 5 and the first four are sequentially arranged on the axis of the laser emitting end One-third of the glass slide 13 and the first beam splitter 6, the first detection objective lens 9, the second pinhole 10 and the first photodetector 11 away from the focal plane, which are arranged on the axis of the reflection end of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com