1-wire bus DCearth fault on-line automatic monitoring apparatus

A DC grounding and automatic monitoring technology, applied in the control field, can solve the problems of irregular construction, component damage, complicated DC circuit wiring, etc., to avoid damage to electrical equipment, save I/O port lines, and facilitate expansion and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

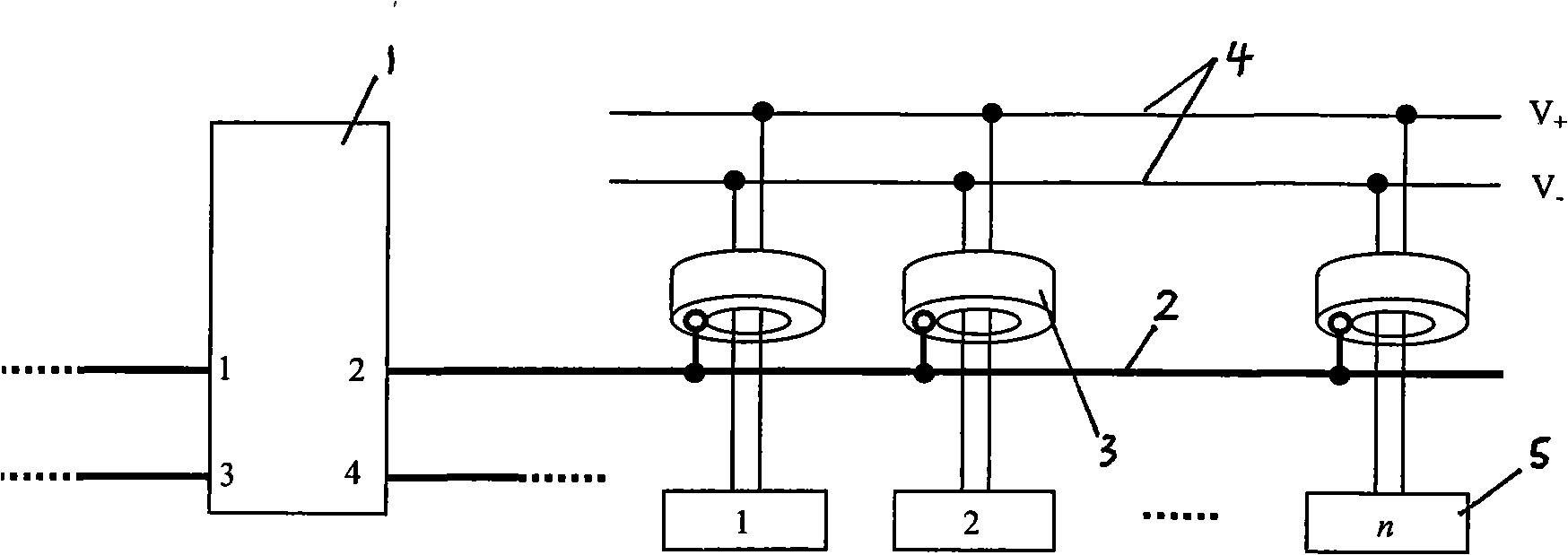

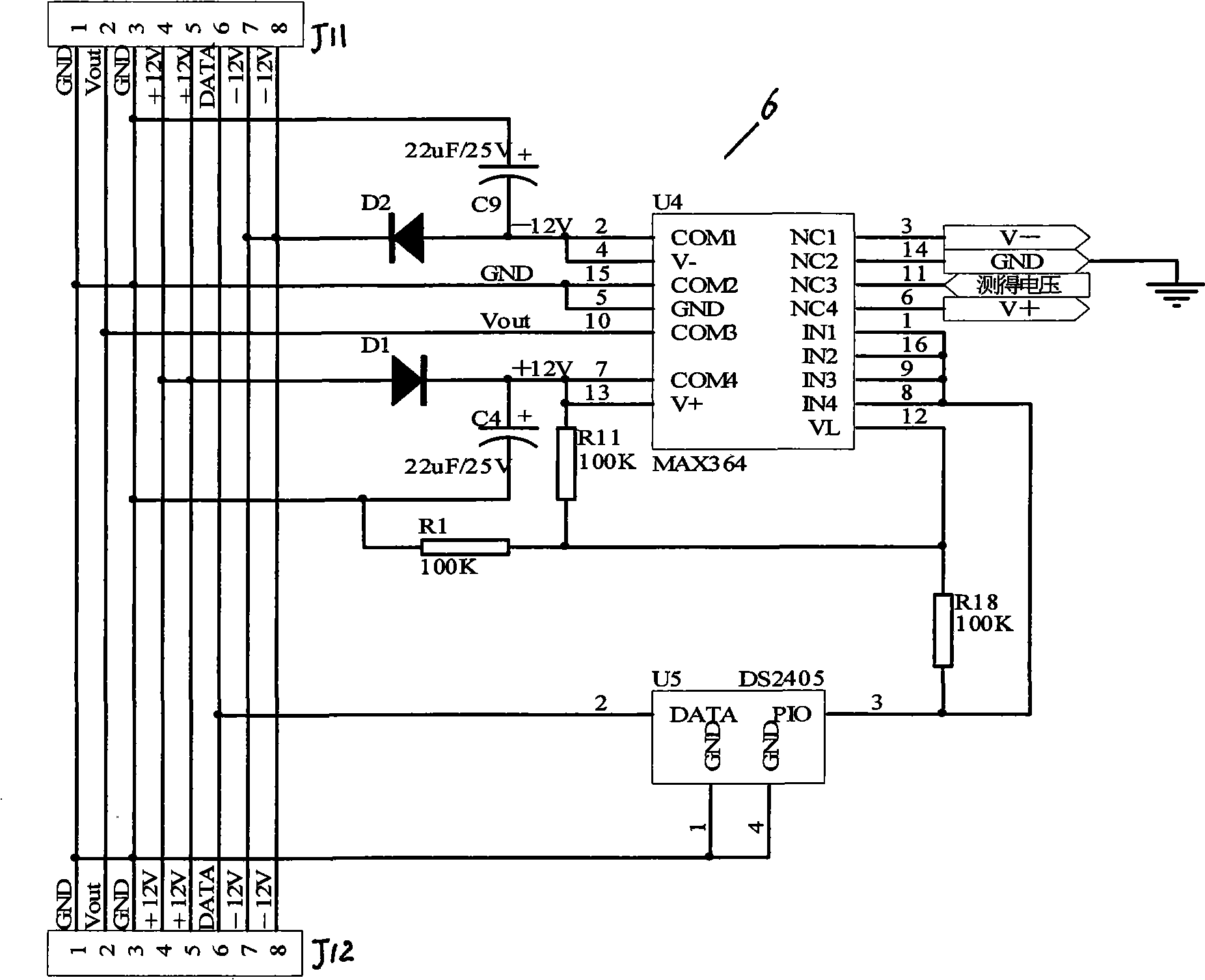

[0030] refer to figure 1 The on-line automatic monitoring device for single-bus DC grounding faults includes sensors 3 and their extended interface circuits 6 connected between several DC branches 5 and the bus 4 . The sensor 3 is connected to the single bus 2 through its extended interface circuit 6 , and the single bus 2 is connected to the host computer 1 . The sensor 3 is a commercially available magnetically modulated DC leakage current sensor.

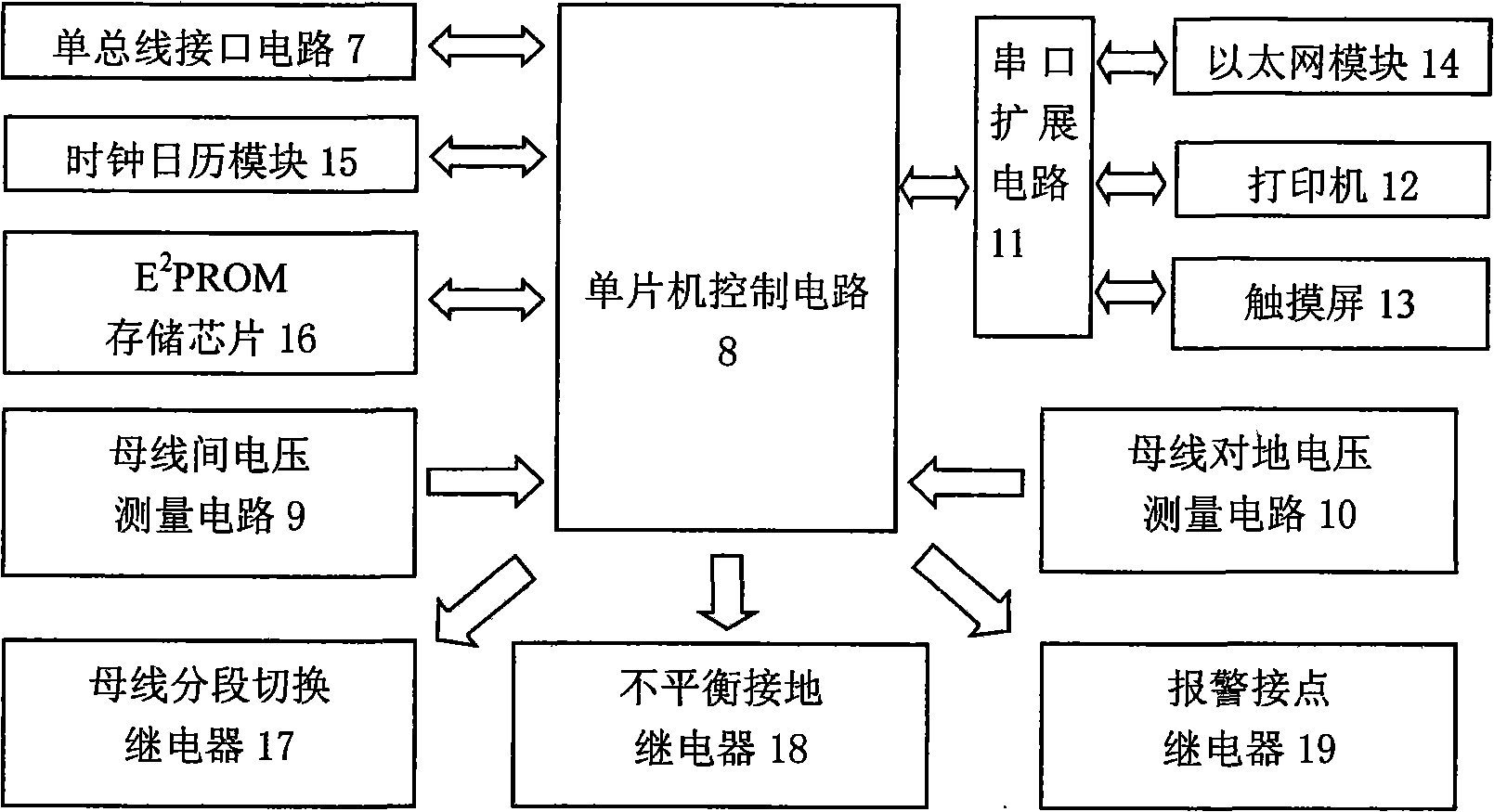

[0031] refer to figure 1 and 2 , the host 1 includes a single-chip control circuit 8, the single-chip control circuit 8 is connected with the single bus 2 through the JTAG interface, and the model is ATMEGA16 single-chip and the single-bus interface circuit 7, the bus voltage measurement circuit 9, and the bus-to-ground voltage measurement circuit respectively 10. Serial port expansion circuit 11. Clock cale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com