Electromagnetical vibrating counter

A technology of electromagnetic vibration and counting machine, applied in vibration conveyors, counting mechanisms/items, conveyors, etc., can solve problems such as inaccurate number of parts, easy disputes, and no better solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

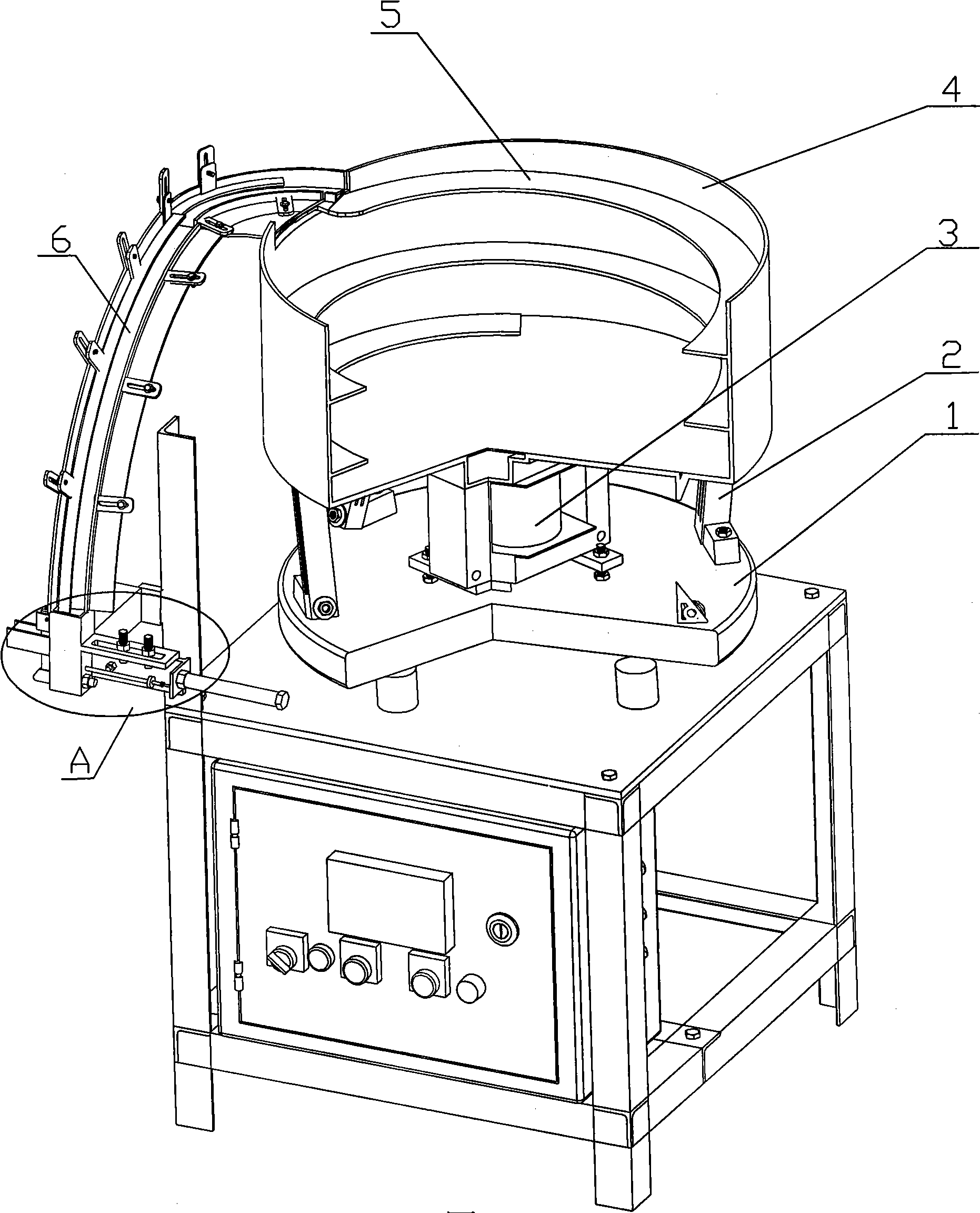

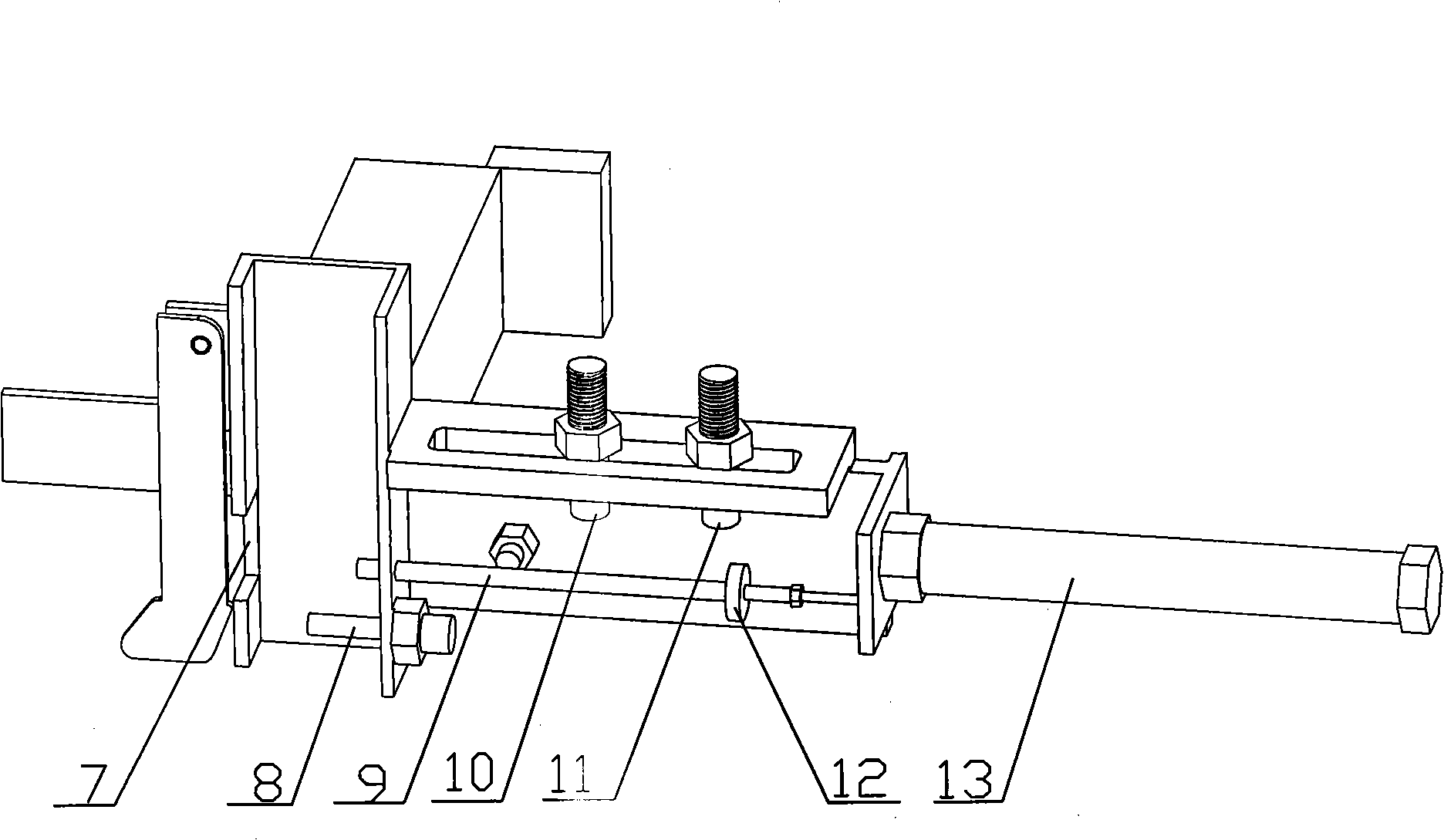

[0012] Such as figure 1 , figure 2 As shown, this embodiment includes a base 1, a vibrating plate 4, an electromagnet 3, a discharge track 6, a counting induction head 8 and a parts pushing device. The side wall of the vibration plate is provided with a right spiral track 5, the electromagnet 3 is fixed on the center position of the base 1 plane, the upper half iron core of the electromagnet 3 is fixed on the bottom of the vibration plate, and the electromagnet 3 is the center, There are several groups of bakelite support bars 2 inclined clockwise and vertically at a certain angle along the circumference of the base 1 , and the upper ends of the bakelite support bars 2 are fixedly connected to the bottom of the vibrating plate 4 . The outlet of the right spiral track 5 on the vibration plate is connected with the discharge track 6, the discharge port 7 is set on the side of the discharge track, and the counting induction head 8 is set on the discharge track 6 at the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com