Piezoelectric vibration energy collecting apparatus with resonance frequency adjustable

A piezoelectric vibration and energy harvesting technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve difficult and precise problems to maximize the energy harvesting capability and overcome the inability to precisely adjust the resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

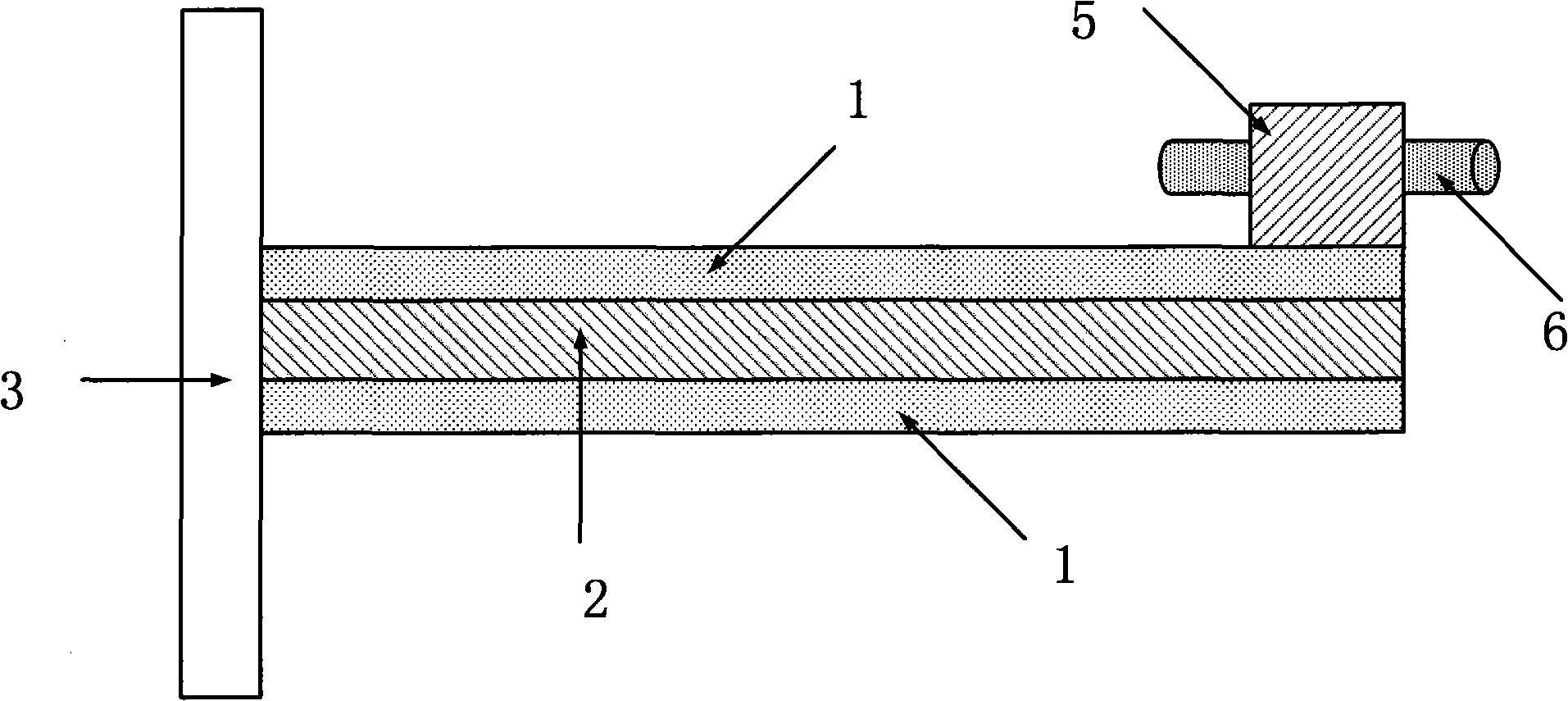

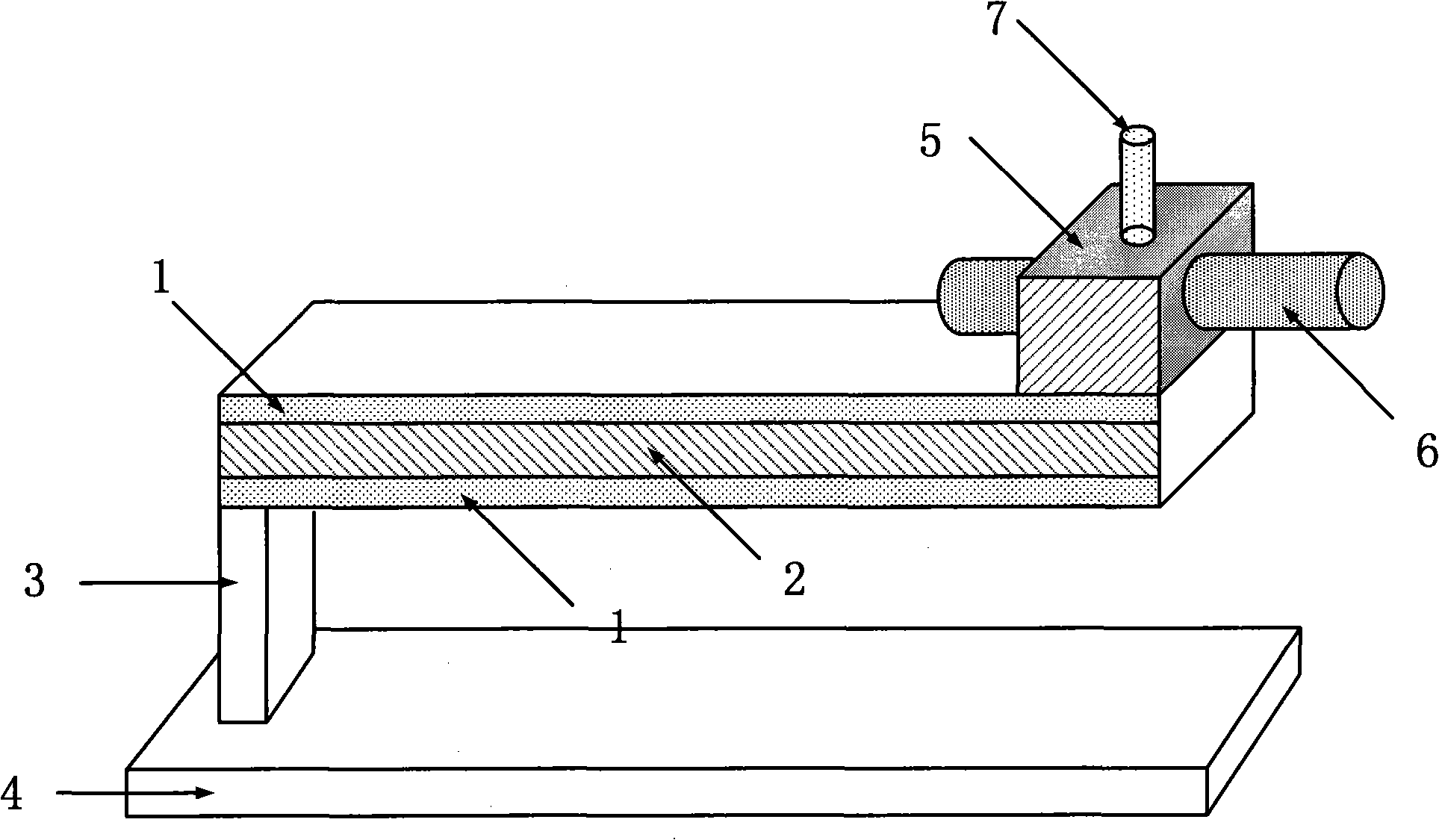

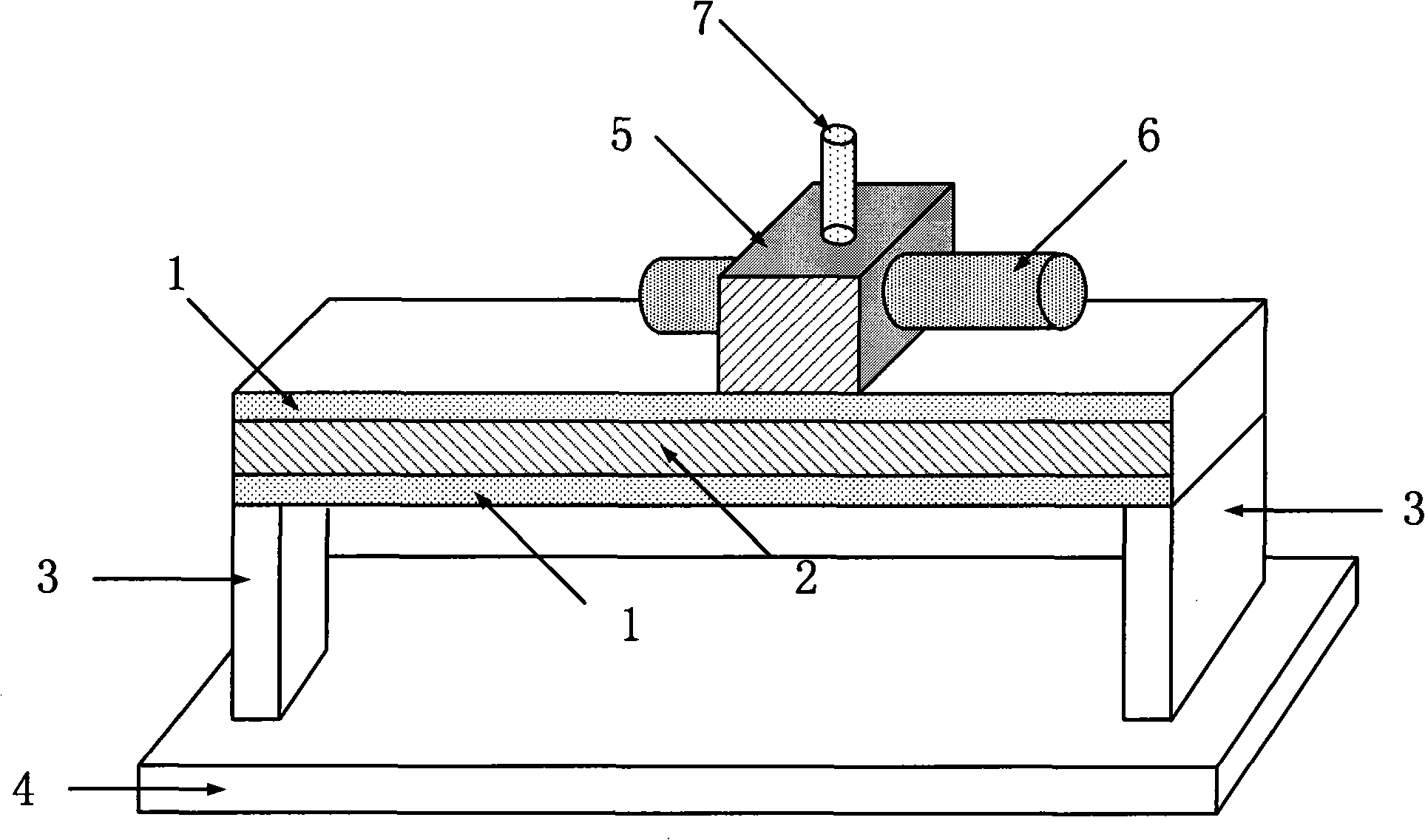

[0018] figure 2 A device according to a preferred embodiment of the invention is shown. The supporting substrate 2 and the piezoelectric layer 1 of the device are fixed on the vibrating platform 4 through the spacer 3 , and then the vibration energy is collected from the vibrating platform 4 . Spacer 3 can be metal, or other materials with greater hardness, to allow the support substrate to be bonded on the spacer, and the thickness should meet the requirements of the relative movement of support substrate 2 and vibration platform 4, so as to avoid support The substrate 2 and the vibration platform 4 collide. The piezoelectric layer 1 is fixed on opposite upper and lower sides of the support substrate 2 . The supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com