Fermentation device comprising a coupled substrate and sediment transport mechanism and method for operating the fermentation device

A fermentation device and substrate technology, applied in the field of fermentation devices, can solve the problems of damage to fermentation tanks, increase production technology costs and management engineering costs, and achieve the effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

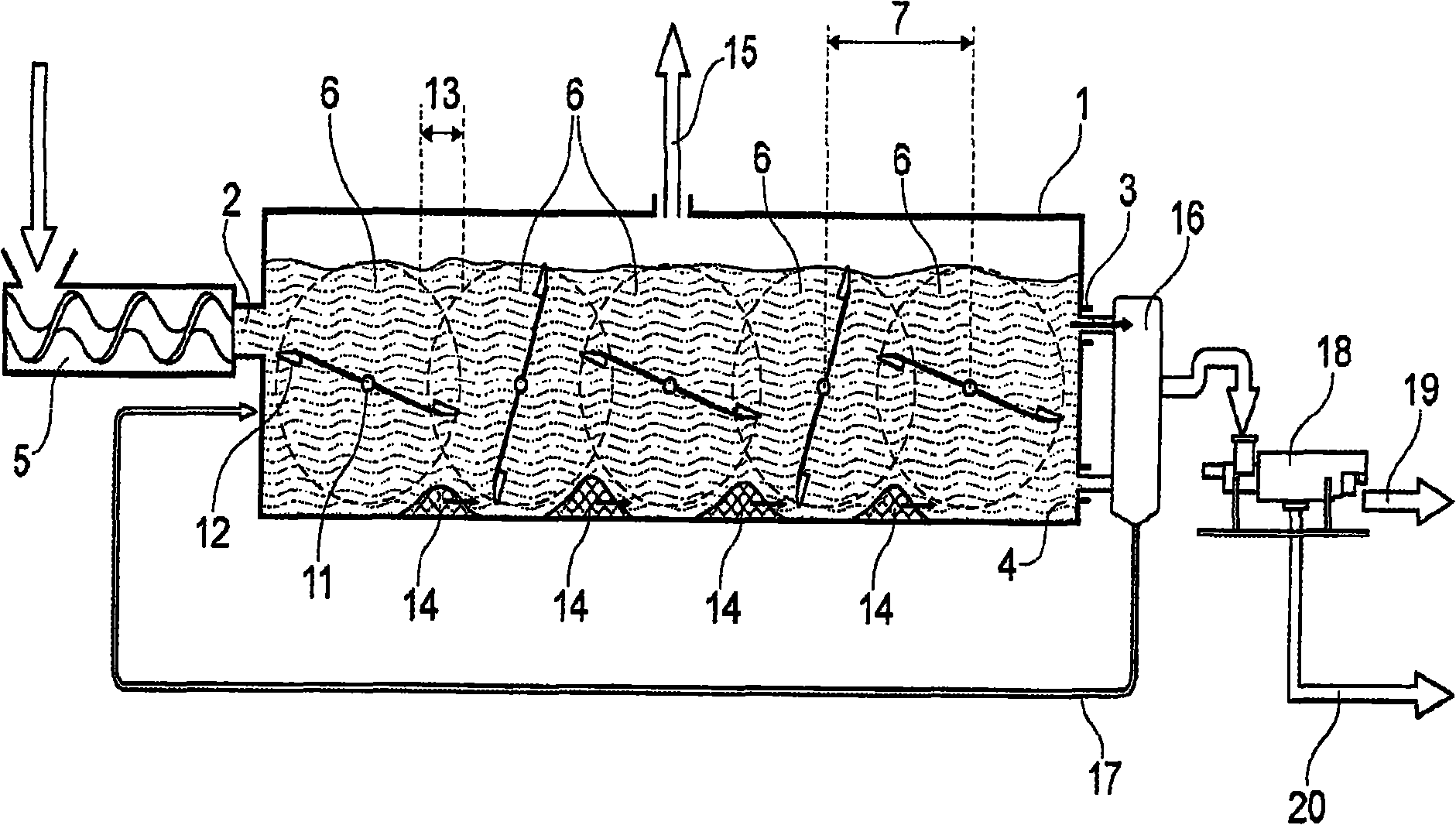

[0022] figure 1 Denotes a fermentation apparatus having a closed horizontal vessel 1 with a feed opening 2 for the substrate to be treated at the front end and discharge openings 3 and 4 at the opposite end. A substrate consisting, for example, of biowaste or recycled raw materials is fed into the feed opening 2 of the container 1 via a feed screw 5 . A plurality of stirring elements 6 arranged transversely to the vessel axis, each having a separately driven stirring shaft 11 oriented transversely to the vessel axis, is arranged in the vessel 1 . Mounted on the stirring blades of the stirring mechanism 6 are a plurality of stirring rods 12 which are spaced apart in relation to the width of the container and are arranged on the stirring shaft at an angle of 120° relative to one another. Furthermore, the stirring shafts 11 are arranged at an axial distance which is smaller than the diameter of the stirring mechanism, so that the stirring rods 12 interlock. Reference numeral 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com