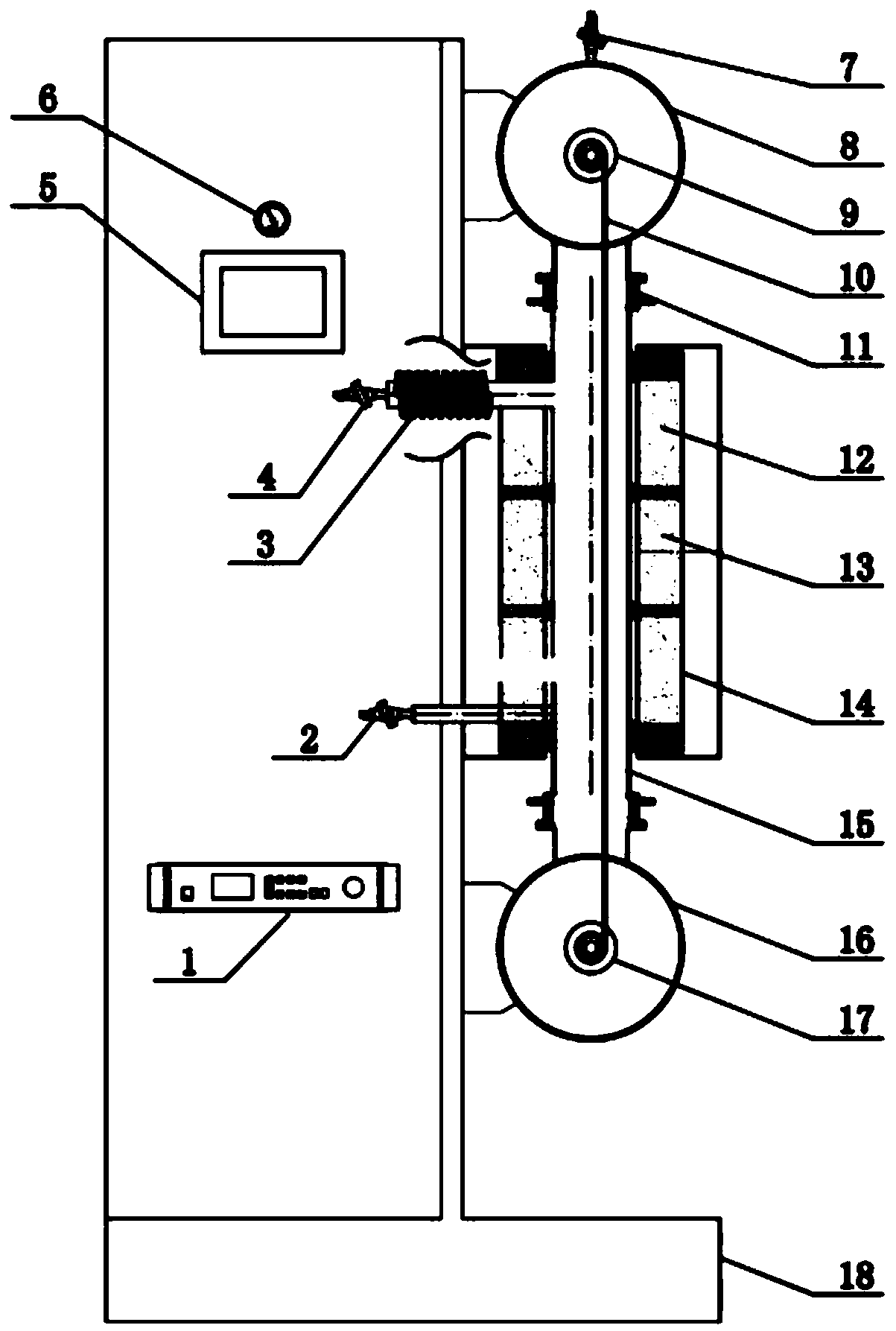

Vertical continuous PE reinforced reel-to-reel graphene film growth equipment

A graphene film, roll-to-roll technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems affecting the effective contact of reactive gases, easy softening and adhesion of copper foil, film interference, etc. Improve the quality and efficiency of film formation, high utilization rate, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0023] Such as figure 1 As shown, a vertical continuous PE enhanced roll-to-roll graphene film growth equipment includes an equipment frame 18, and the front end outer surface of the equipment frame 18 is sequentially installed with a pressure gauge 6, a touch control screen 5 and a radio frequency Controller 1, wherein the model adopted by radio frequency controller 1 is RF, a quartz tube 15 is installed on one side of the equipment frame 18, and an unwinding cabin 8 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com