Ozone generating electrolysis cell

An ozone generation and electrolytic cell technology, which is applied to electrolytic components, electrolytic processes, electrodes, etc., and can solve the problems of unstable operation, decomposition, and unstable compounds of electrolytic cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

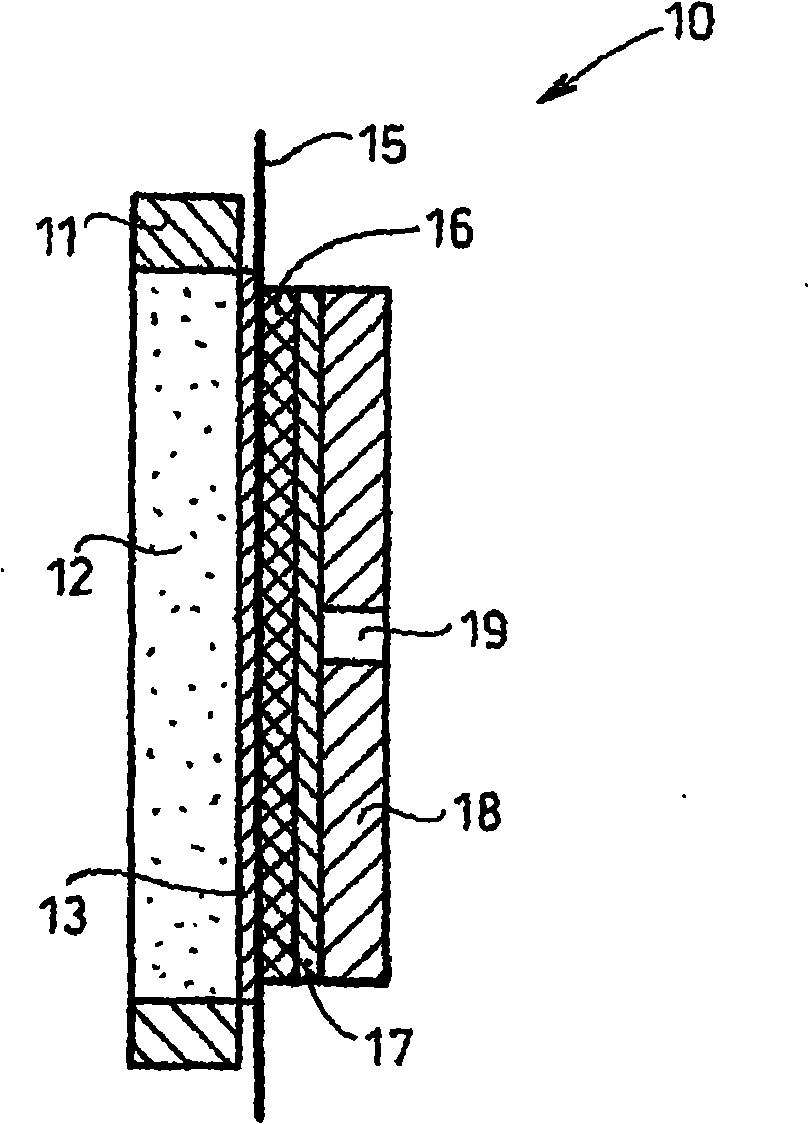

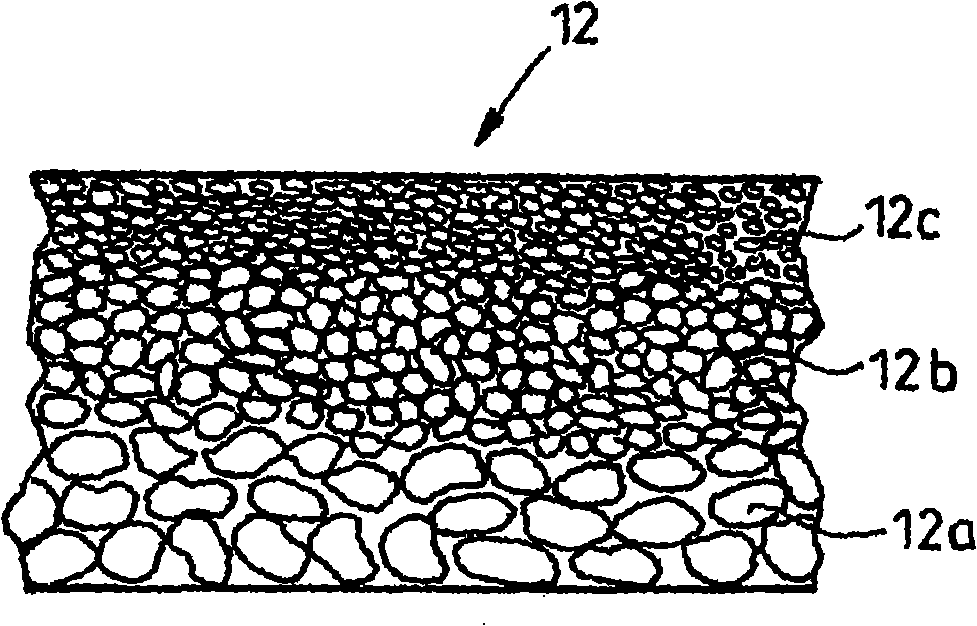

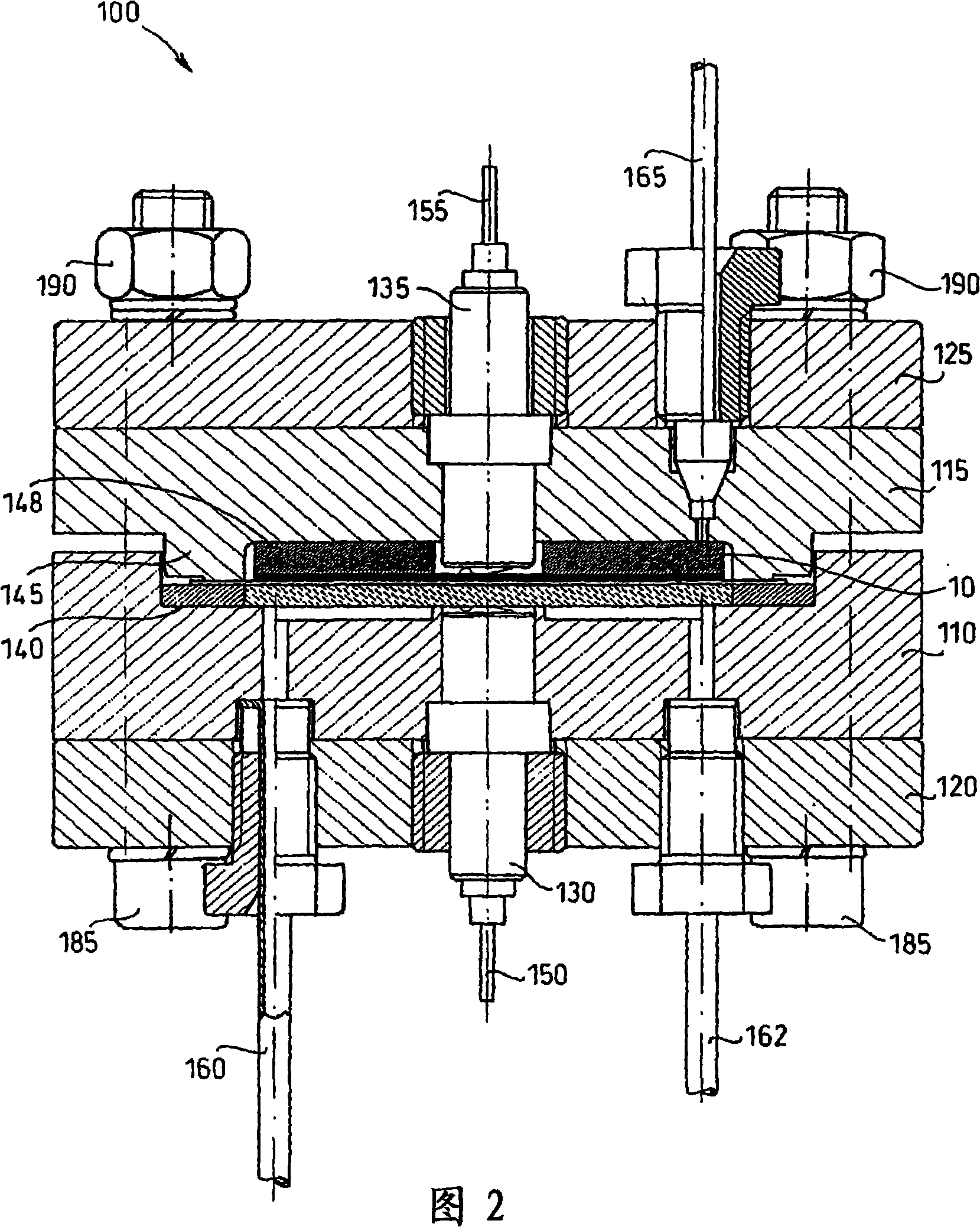

[0017] used in the ozone generating electrolytic cell according to the present invention Figure 1A The electrode structure 10 mainly comprises a negative electrode (or negative electrode) 13, an ozone generating positive electrode (or anode) 16, a proton exchange membrane 15 arranged between the electrodes 13, 16, and the positive electrode 16 connected to the A first (positive electrode or anode side) electrode support 17 on the opposite side of the membrane 15 . The electrode support 17 is arranged on a (anode-side) support 18 which is provided with through-openings 19 for electrical contacting. The electrode 13 is formed on a second (cathode side) electrode support 12 provided on the (cathode side) support 11 .

[0018] The electrode support 12 serves on the one hand to provide electrical contact between an external DC power source (not shown) and the negative electrode 13, and on the other hand to direct the water required for electrolysis to the electrode 13 and to allow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap